Fluorescent carbon quantum dot composite light-emitting material, preparation method therefor and application on LED

A technology of carbon quantum dots and luminescent materials, which is applied in the fields of fluorescent carbon quantum dot composite luminescent materials and its preparation and application in LEDs. problems, and achieve the effects of low cost, short production cycle and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Preparation of silane-functionalized fluorescent carbon quantum dots: under nitrogen protection, preheat 100mL of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane in vacuum to 240°C and perform magnetic Stir. 4 g of anhydrous citric acid was quickly added to the above solution, and after constant temperature reaction for 5 minutes, it was taken out and cooled to room temperature. The crude product was purified three times with petroleum ether to obtain a silane-functionalized fluorescent carbon quantum dot solution.

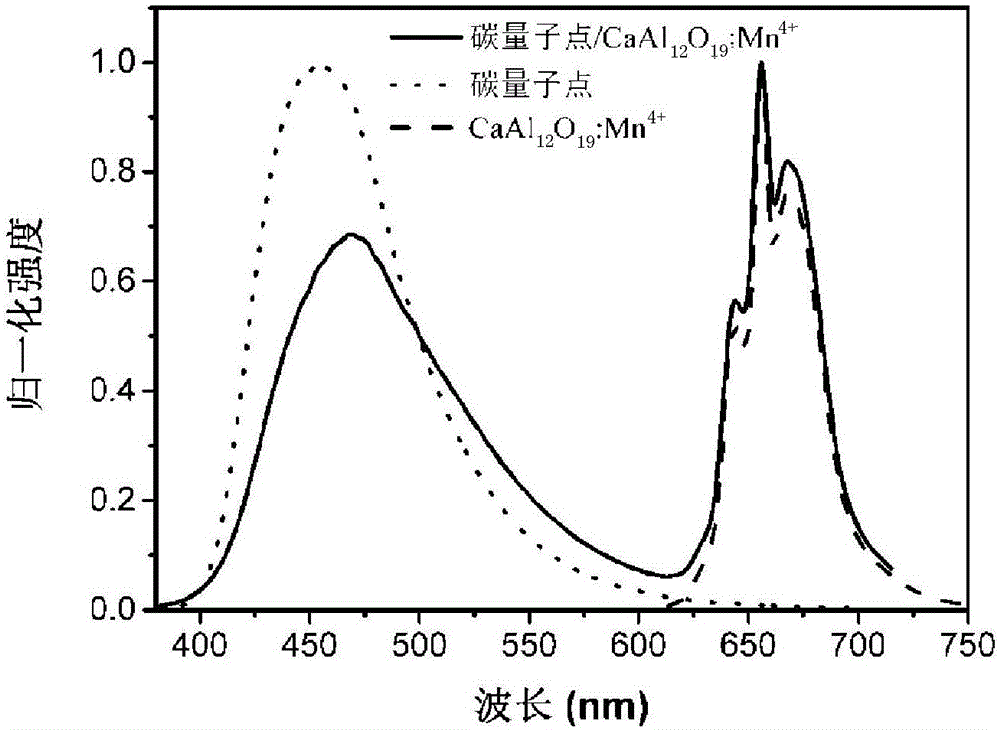

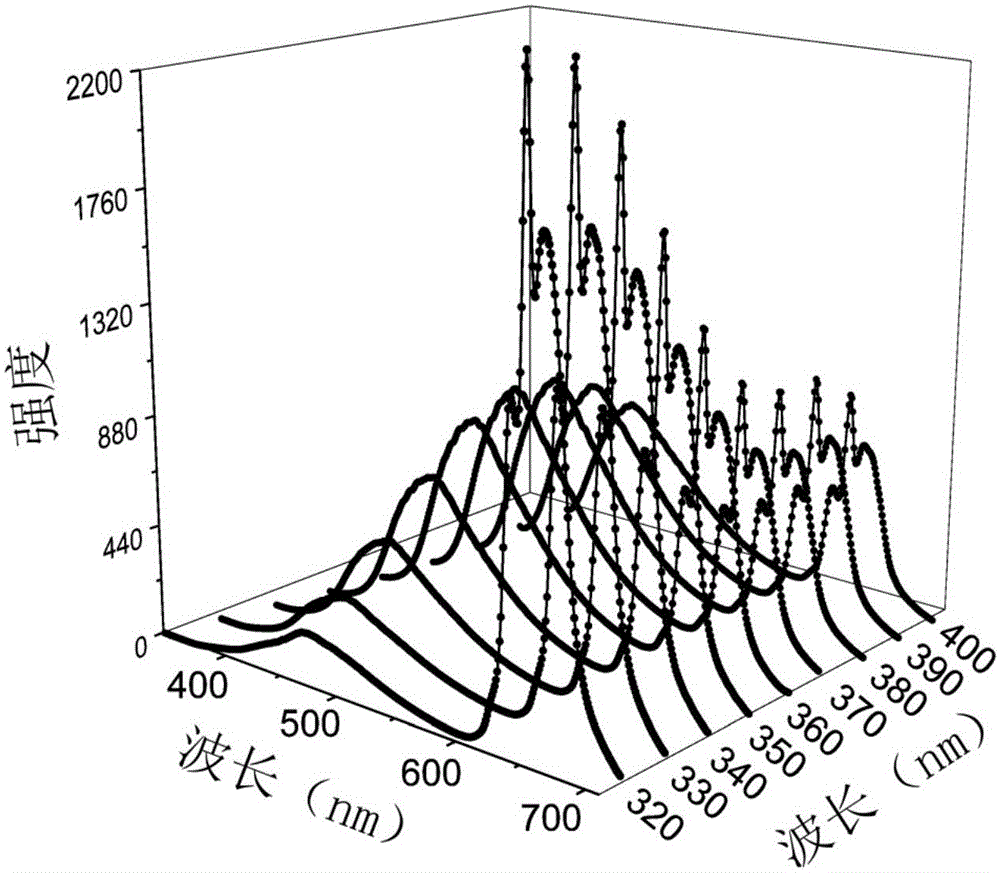

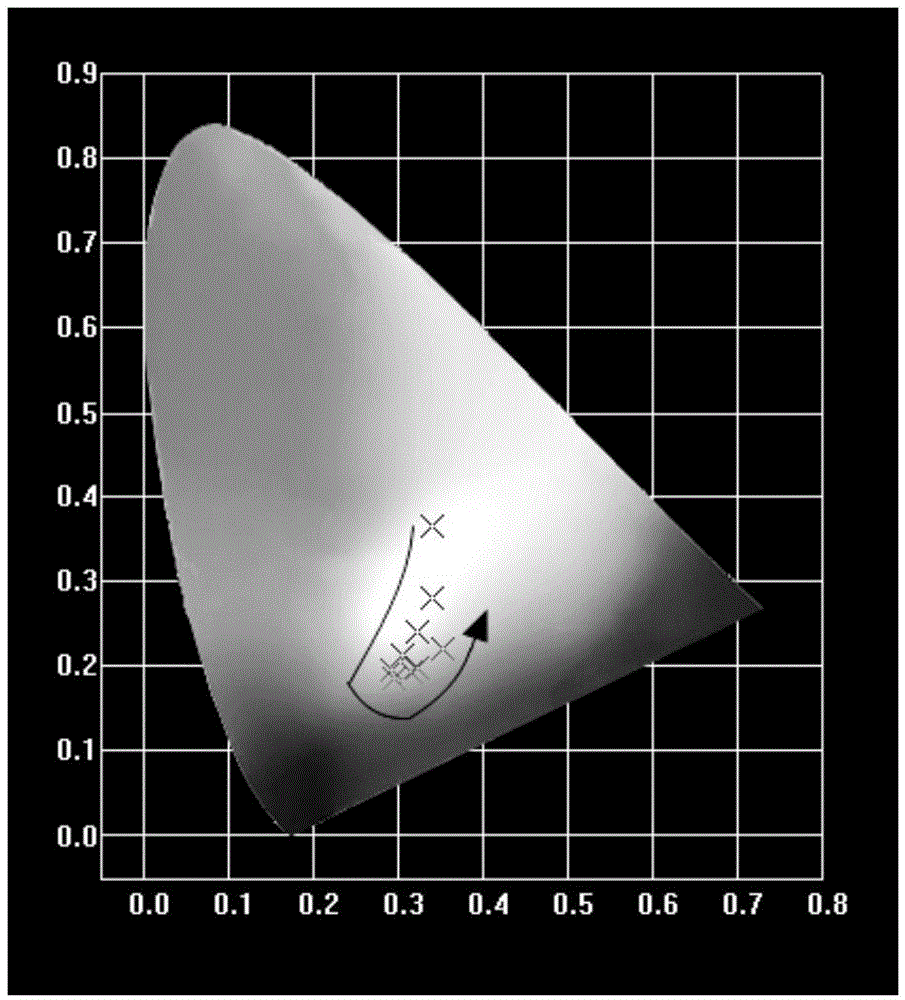

[0060] (2) Fluorescent carbon quantum dots / CaAl 12 o 19 :Mn 4+ Preparation of fluorescent powder composite luminescent material: Weigh 0.005 g of the silane-functionalized carbon quantum dot solution prepared in step (1), add 1 mL of absolute ethanol, and adjust the pH to 6.5 with 2 mol / L hydrochloric acid solution. Then add 8 mL of ethyl orthosilicate, absolute ethanol, distilled water, 2mol / L hydrochloric acid mixed solution, ethyl orthosilicate: ab...

Embodiment 2

[0070] (1) Preparation of silane-functionalized fluorescent carbon quantum dots: under the condition of nitrogen protection, preheat 100mL N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane in vacuum to 180°C and carry out Magnetic stirring. 1 g of anhydrous citric acid was quickly added to the above solution, and after constant temperature reaction for 10 minutes, it was taken out and cooled to room temperature. The crude product was purified three times with petroleum ether to obtain a silane-functionalized fluorescent carbon quantum dot solution.

[0071] (2) Fluorescent carbon quantum dots / Sr 2 Si 5 N 8 :Eu 2+ Preparation of fluorescent powder composite luminescent material: Weigh 0.01 g of the silane-functionalized carbon quantum dot solution prepared in step (1), add 1 mL of absolute ethanol, and adjust the pH to 4.0 with 2 mol / L hydrochloric acid solution. Then add 3 mL of ethyl orthosilicate, absolute ethanol, distilled water, 2mol / L hydrochloric acid mixed solution, e...

Embodiment 3

[0075] (1) Preparation of silane-functionalized fluorescent carbon quantum dots: under the condition of nitrogen protection, preheat 100mL N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane in vacuum to 250°C and carry out Magnetic stirring. 7 g of anhydrous citric acid was quickly added to the above solution, and after constant temperature reaction for 30 minutes, it was taken out and cooled to room temperature. The crude product was purified three times with petroleum ether to obtain a silane-functionalized fluorescent carbon quantum dot solution.

[0076] (2) Fluorescent carbon quantum dots / 3.5MgO·0.05MgF 2 · GeO 2 :Mn 4+ Preparation of fluorescent powder composite luminescent material: Weigh 1 g of the silane-functionalized carbon quantum dot solution prepared in step (1), add 5 mL of absolute ethanol, and adjust the pH to 7.0 with 2 mol / L hydrochloric acid solution. Then add 20mL of ethyl orthosilicate, dehydrated alcohol, distilled water, 2mol / L hydrochloric acid mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com