Functionalized graphene composite fused salt

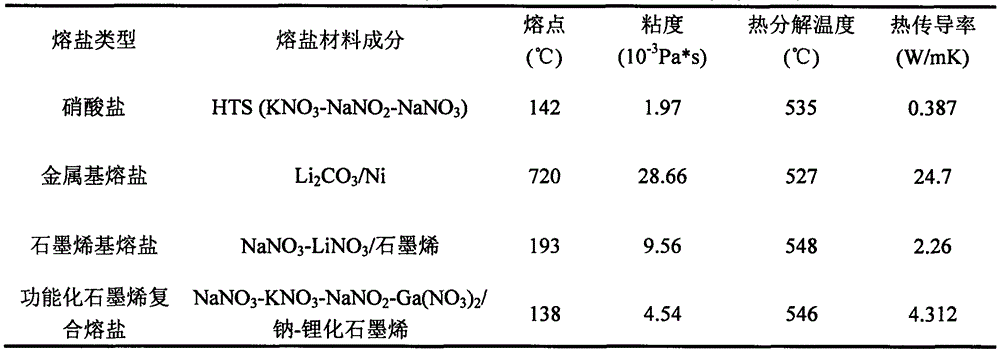

A graphene composite and functionalization technology, applied in the field of molten salt, can solve the problems of low melting point and low thermal conductivity of graphite-based molten salt composite materials, and achieve the effects of improving thermal stability, high heat storage density and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through examples.

[0020] Preparation of functionalized graphene composite molten salt:

[0021] Add 1 g of graphene oxide to 100 mL of deionized water for ultrasonic dispersion, and dropwise add an aqueous solution of 1.0 mol / L hydroxide. The hydroxide is a mixture of sodium hydroxide and lithium hydroxide, and the mass ratio of sodium hydroxide to lithium hydroxide is 100.0 : 10.0, and sodium-lithium graphene was obtained by separation after the reaction. The mixture composed of 44% sodium nitrate, 16% potassium nitrate, 33% sodium nitrite and 7% calcium nitrate was dried in an oven at 120°C, and after mechanical mixing, placed in a heater with an ultrasonic and stirring device, The temperature is raised until the molten salt is melted, and then functionalized graphene is added, and the mass ratio of functionalized graphene and molten salt is 20:100. Ultrasonic, stirring and mixing, and grinding to powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com