Screw support device and twin-screw extruder with same

A twin-screw extruder and support device technology, applied in the field of screw support devices, can solve problems such as melt conveying capacity drop, melting capacity drop, pressure fluctuation, etc., to reduce equipment maintenance costs, reduce downtime, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

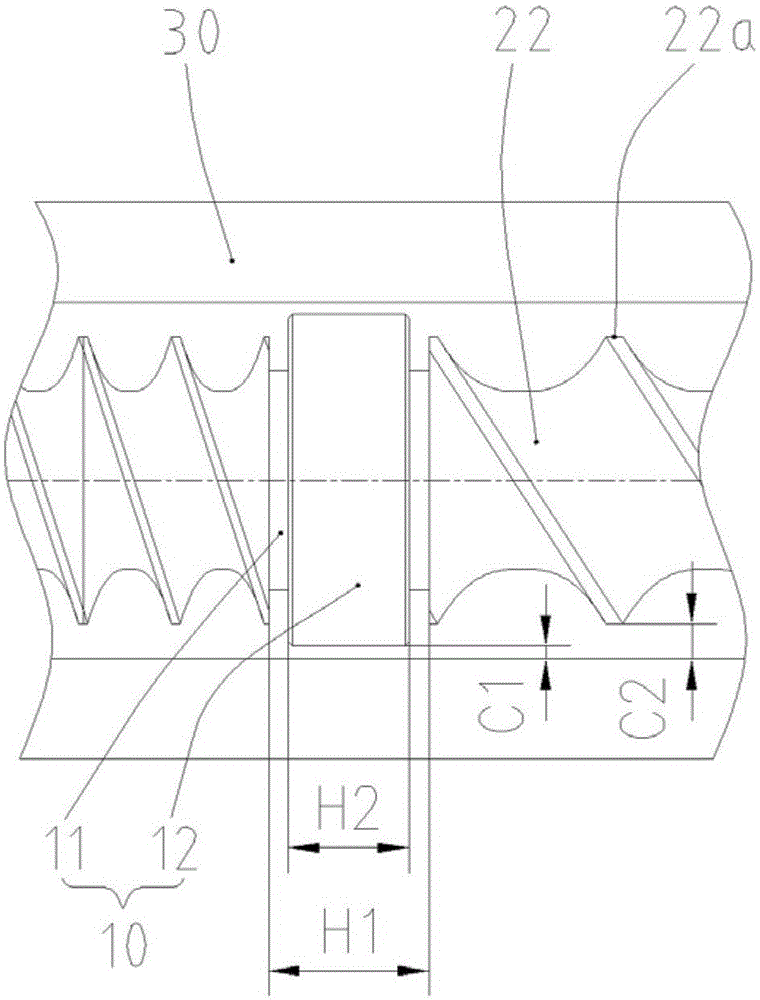

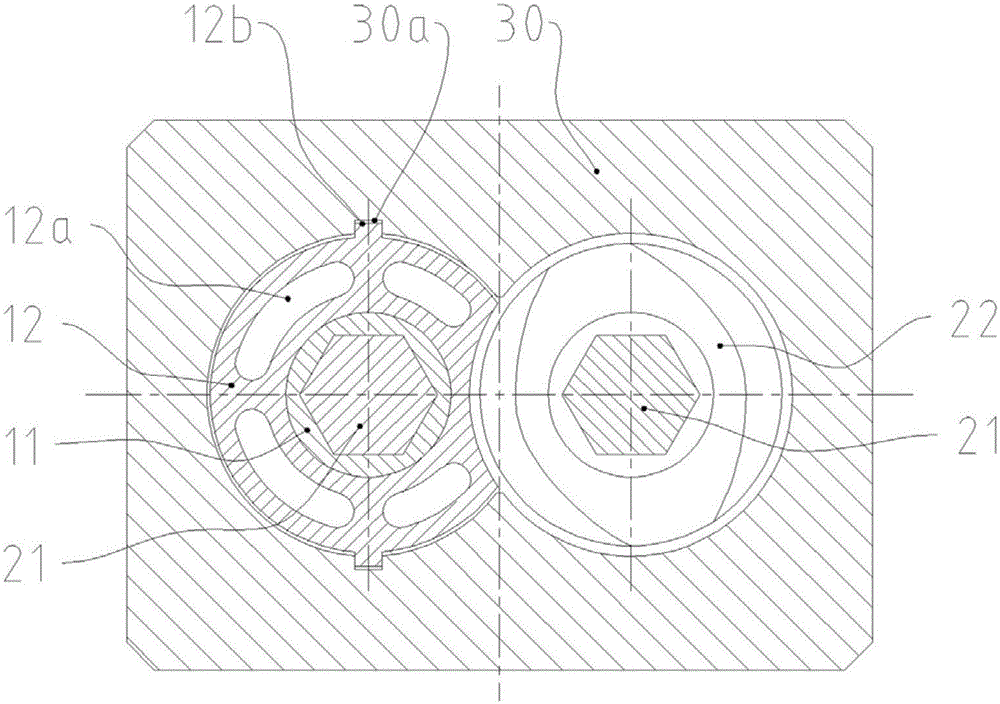

[0050] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims without being limited to the embodiments described herein. In addition, these embodiments are for the purpose of fully disclosing the present invention and facilitating a complete understanding of the scope of the claims by those skilled in the art. For ease of description, the size and relative size of each layer and area in the figure are exaggerated. The same reference numerals refer to the same elements in the figures.

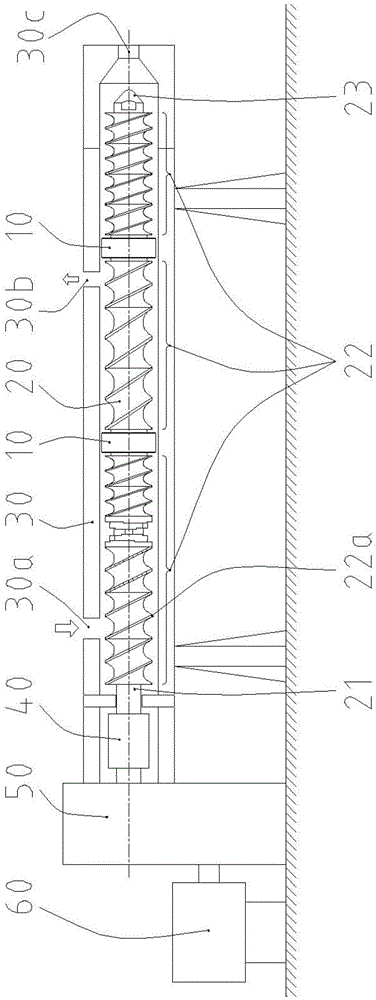

[0051] Such as Figure 1A As shown, in the twin-screw extruder, the power is provided by the motor 60, and the torque is distributed and decelerated through the gear box 50. The screw 20 is connected with the output shaft of the gear box 50 through the connecting sleeve 40, and the material enters the barrel through the feeding port 30a. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com