Segmented ferroalloy casting machine and process method for producing ferroalloy casting pellets

A ferroalloy and granulator technology, which is applied in the field of continuous production of ferroalloy ingot forming, can solve problems such as reducing the service life of related equipment, affecting the operation accuracy and running stability of the granulator system, and small effective volume of the mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

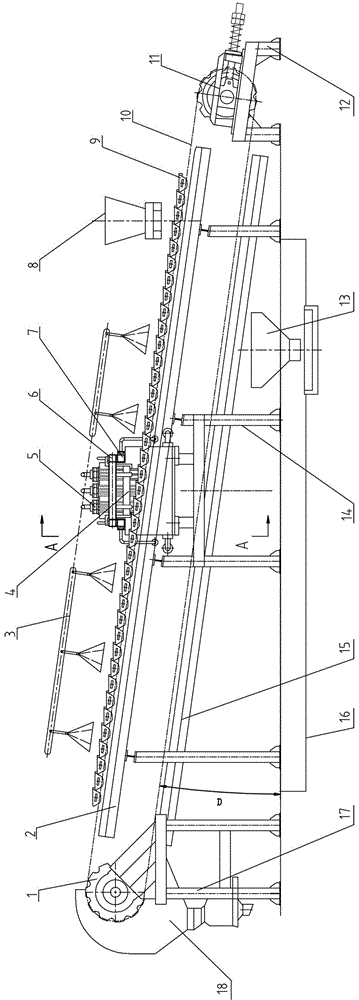

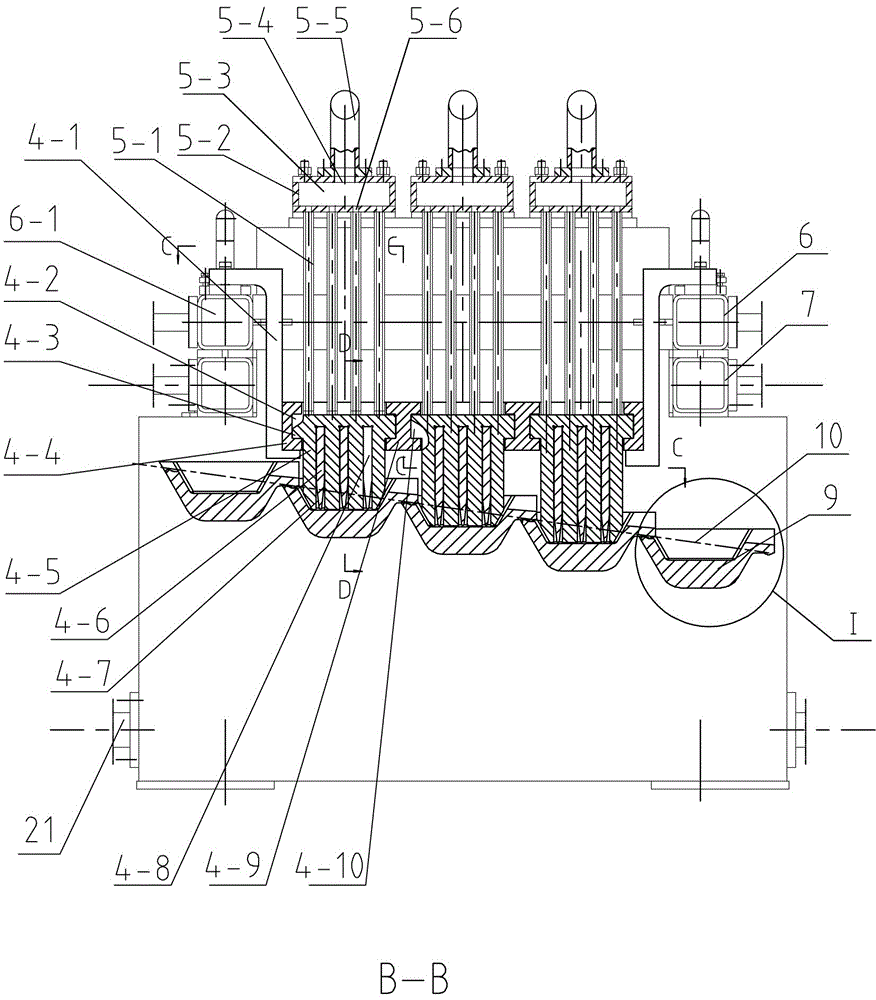

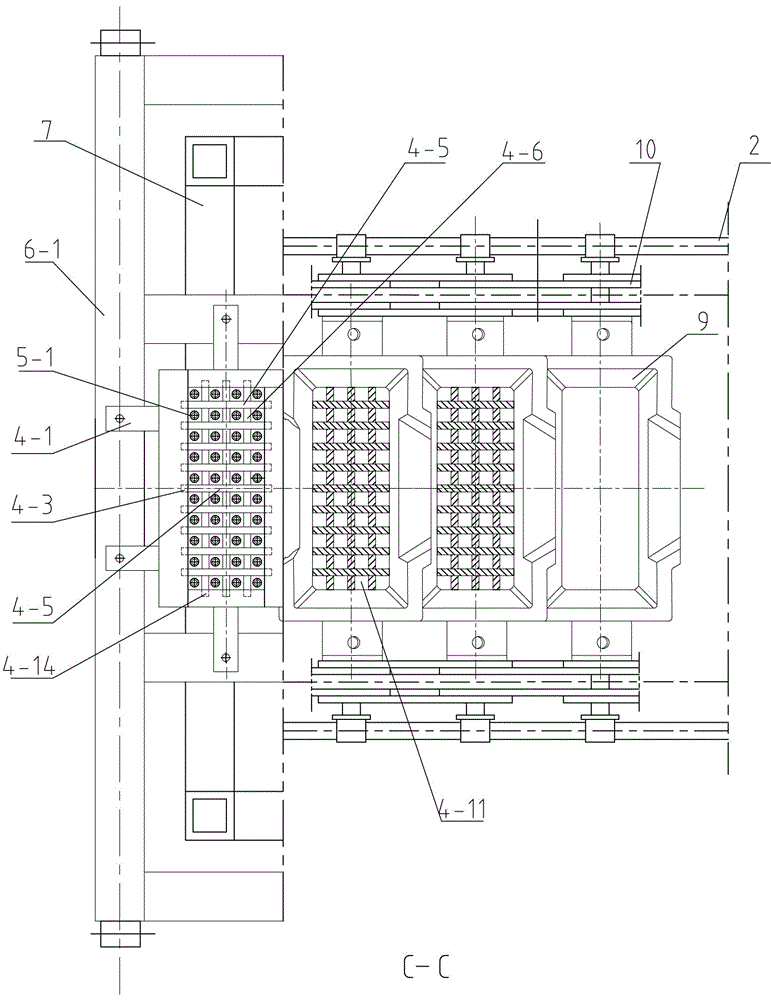

[0052] Such as figure 1 As shown, the split-type ferroalloy casting machine of the present invention includes an equipment frame, a chain drive device 1 located at the head of the equipment frame, and a material block finished material receiving device 18 located below the chain drive device 1. The chain tensioner 11 at the tail of the equipment rack is longitudinally arranged on the upper double-row inclined track 2 of the equipment rack respectively, and the lower double-row inclined track 15 parallel to the upper double-row inclined track 2 is respectively connected with The upper double-row inclined track 2 and the two annular plate conveyor chains 10 that are rollingly connected to the lower double-row inclined track, the cooling spray system 3 above the two annular plate conveyer chains 10, and the ferroalloy liquid casting i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com