Device for removing powder coating

A cleaning device and powder coating technology, applied in the direction of spraying devices, etc., can solve the problems of dust permeating in the air, cumbersome manual powder cleaning, and polluting the working environment, so as to avoid pollution, improve powder cleaning efficiency, and good powder cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

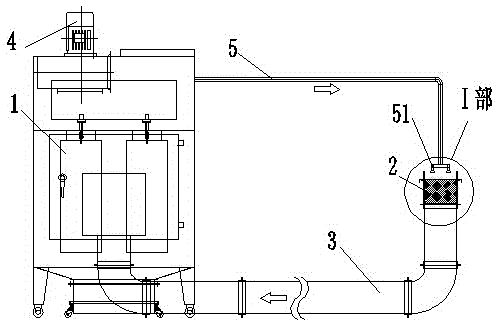

[0019] The present invention includes a powder recovery chamber 1 and a containment device 2 arranged outside the powder recovery chamber 1; one end of the containment device 2 is provided with an exhaust fan 4 that absorbs the content powder into the powder recovery chamber 1 through a suction pipe 3, so that The air outlet of the exhaust fan 4 extends to the other end of the accommodating device 2 through a blowing pipe 5 .

[0020] A blowing nozzle 51 is arranged at the end of the blowing pipe 5, and the blowing nozzle 51 is rotatably arranged.

[0021] Filtering devices are arranged on the paths of the exhaust pipe 3 and the air blowing pipe 5 .

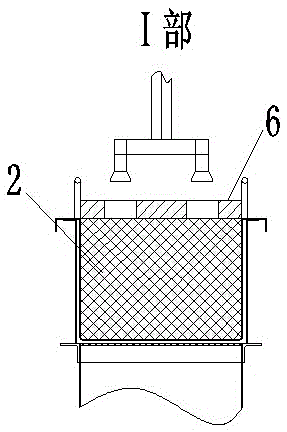

[0022] The exhaust pipe 3 is arranged on the lower part of the container 2, the blowing pipe 5 is arranged on the upper part of the container 2, and the upper part of the container 2 is provided with a cover 6;

[0023] The cover 6 is provided with a through hole corresponding to the blowing nozzle 51 , and the blowing nozzle 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com