A filter barrel for solar cell manufacturing process

A technology of solar cells and filter barrels, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of small debris splashing, increase production cost, waste of slurry, etc., and achieve the structure of the filter barrel. Robustness, ease of manufacture and mass production, improved filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] In actual use, the filter barrel is used with the upper opening of the housing on the upper side and the lower opening on the lower side. The upper and lower in this embodiment correspond to the upper pressing plate and the lower pressing plate of the filter cartridge respectively.

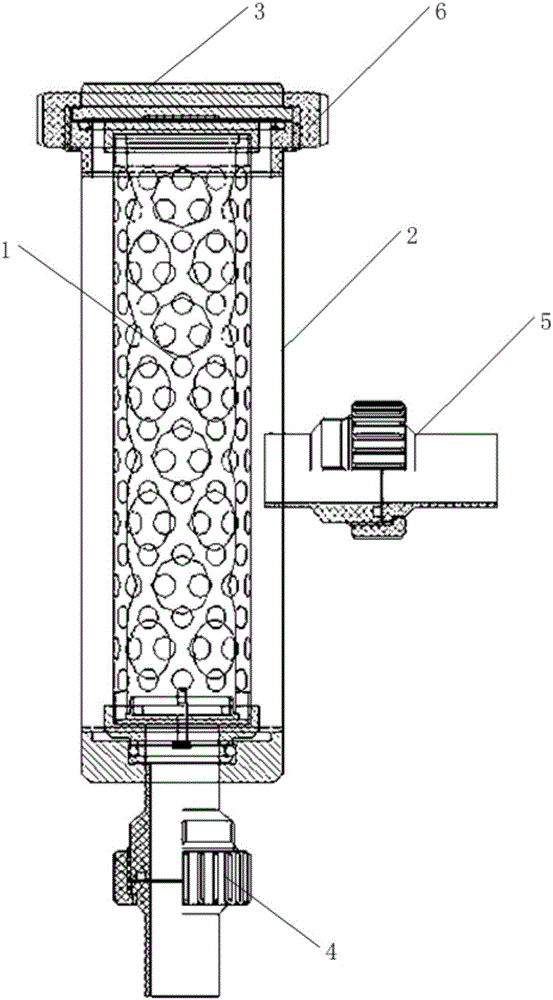

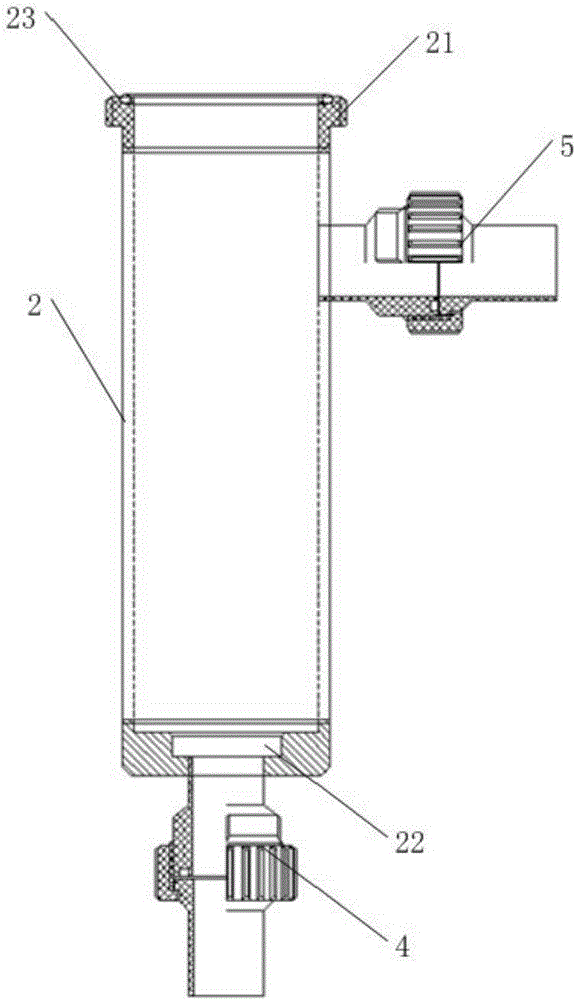

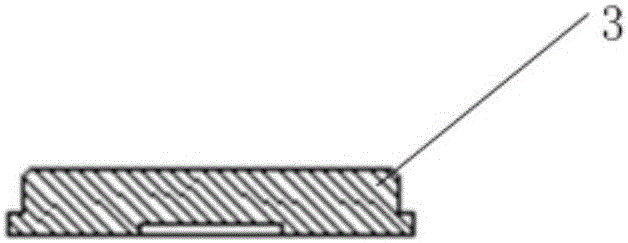

[0042] See Figure 1-Figure 8, the embodiment of the present invention provides a filter barrel for solar cell manufacturing process, including a housing 2 made of non-metallic materials, an upper cover 3, a filter cartridge 1, a liquid inlet joint 4 and a liquid outlet joint 5,

[0043] The housing 2 is a hollow cylindrical structure, and the two ends of the housing 2 have an upper opening and a lower opening respectively; There is a gap between the inner walls of the body 2; the upper cover 3 is arranged on the upper opening of the housing 2 to block the upper opening, and the liquid inlet joint 4 is connected to the lower opening of the housing 2; The liquid outlet joint 5 is arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com