Aroma brewing flavor for cigarettes and application thereof in improving smoking quality of cigarettes

A spice and aroma brewing technology, which is applied in the field of improving the smoking quality of cigarettes, compound fermentation of glutinous rice, tobacco and flavor material raw materials, and can solve the problems that affect the style characteristics and sensory quality of cigarettes, reduce the user's throat comfort, and smoke. The problem of increased gas irritation, etc., achieves the effect of good cigarette application effect, enriches the aroma of cigarettes, and reduces irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

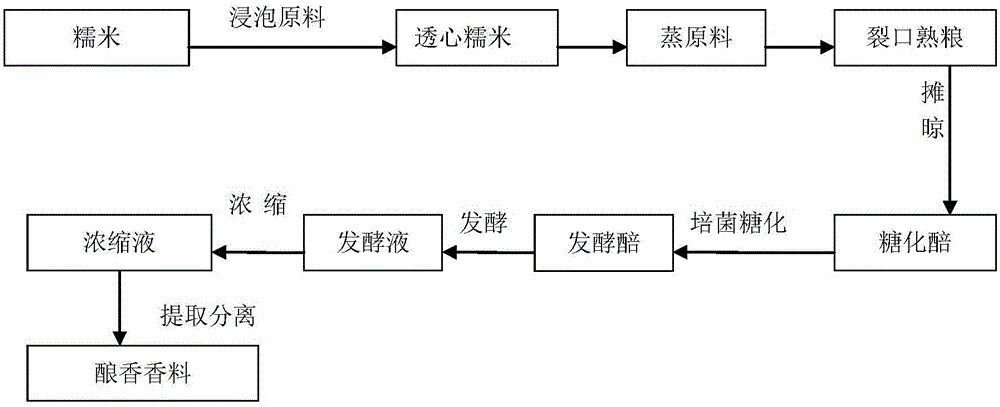

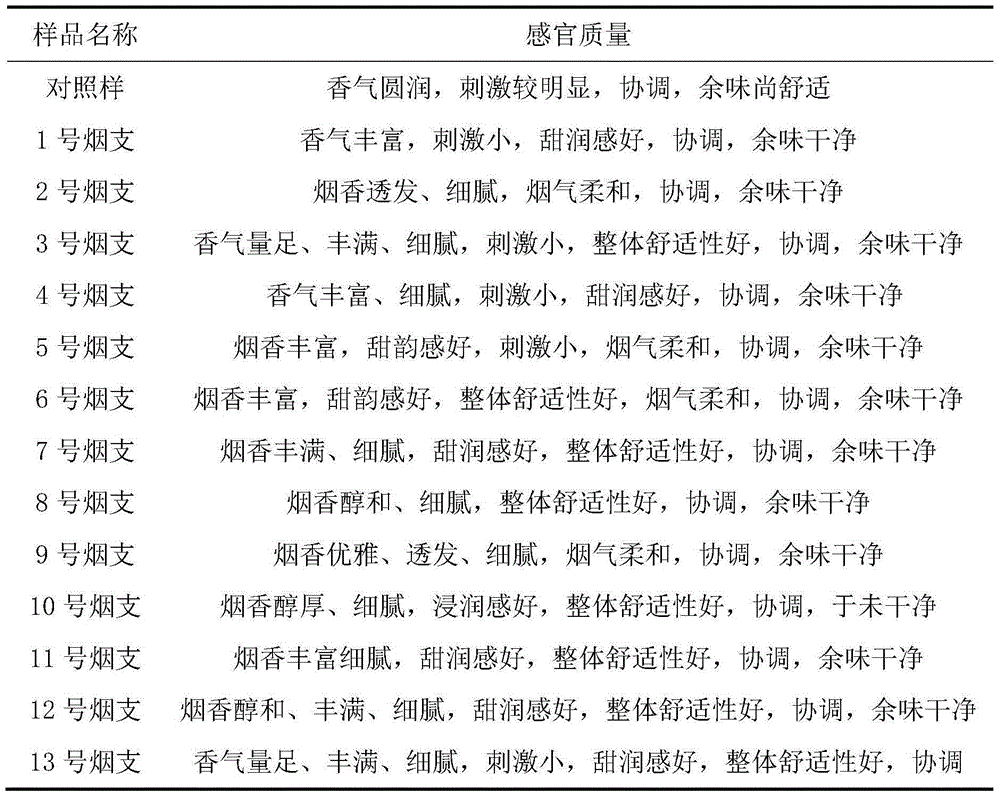

Embodiment 1

[0044] The glutinous rice was washed and soaked in distilled water for 20 hours. After draining, the glutinous rice, shredded tobacco and green tea were steamed at 120°C for 40 minutes until there was no white heart. When steamed glutinous rice, tobacco and green tea were naturally cooled to 30°C, rice koji, yeast and Bacillus pumilus C-5 (strain preservation number: BRIL00540) were inoculated for saccharification and fermentation, rice koji, yeast and Bacillus pumilus C- 5, the inoculum amounts were 0.6%, 0.07%, and 0.25%. The saccharification temperature is 29°C. After saccharification for 24 hours, distilled water is added at a water ratio (volume ratio) of 1:1, fermented at 29°C for 5 days to obtain a fermented liquid, which is directly concentrated, and then liquid glutinous rice and tobacco are prepared by extraction, freezing, separation, and concentration. Green tea compound fermented spices. Take 0.15g of glutinous rice, tobacco and green tea compound fermentation ar...

Embodiment 2

[0046] The glutinous rice was washed and soaked in distilled water for 25 hours. After draining, the glutinous rice, shredded tobacco and angelica were steamed at 100°C for 40 minutes until there was no white heart. Inoculate rice koji, yeast and Bacillus pumilus M-4 (strain preservation number: BRIL00543) when steamed glutinous rice, shredded tobacco and angelica are naturally cooled to 32°C for saccharification and fermentation, rice koji, yeast and Bacillus pumilus M-4 The inoculum amounts were 0.7%, 0.05%, and 0.1%. The saccharification temperature is 25°C. After 36 hours of saccharification, add distilled water at a water ratio (volume ratio) of 1:1, ferment at 25°C for 7 days to obtain a fermented liquid, concentrate directly, and then prepare liquid glutinous rice and tobacco by extraction, freezing, separation, and concentration. Angelica compound fermented aromatic spices. Take 0.25g of glutinous rice, tobacco and angelica composite fermentation fragrance brewing spi...

Embodiment 3

[0048] The glutinous rice was washed and soaked in distilled water for 25 hours. After draining, the glutinous rice, shredded tobacco, lavender and moringa were steamed for 40 minutes at 100°C until no white heart was found. When steamed glutinous rice, shredded tobacco, lavender and Moringa were naturally cooled to 32°C, rice koji, yeast and Bacillus pumilus M-4 (strain preservation number: BRIL00543) were inoculated for saccharification and fermentation, rice koji, yeast and Bacillus pumilus M The inoculum amounts of -4 were 0.7%, 0.05%, and 0.1%, respectively. The saccharification temperature is 25°C. After saccharification for 36 hours, distilled water is added at a water ratio (volume ratio) of 1:1, fermented at 25°C for 7 days to obtain a fermented liquid, which is directly concentrated, and then extracted, frozen, separated, and concentrated to prepare liquid glutinous rice and tobacco. Lavender and Moringa compound fermented aromatic spices. Take 0.25g of glutinous ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com