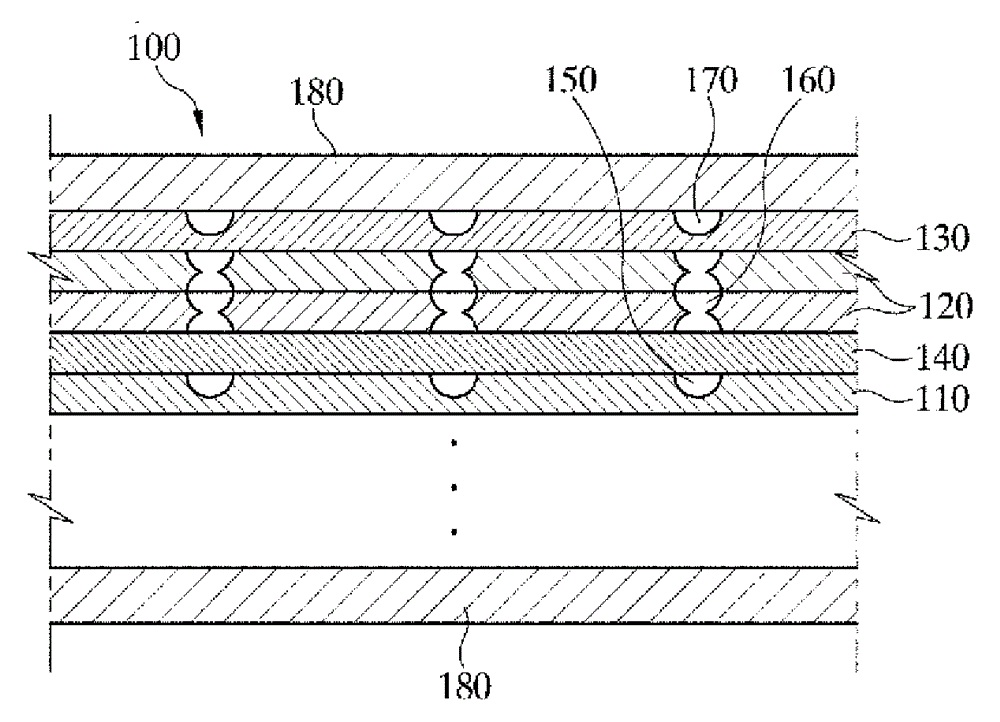

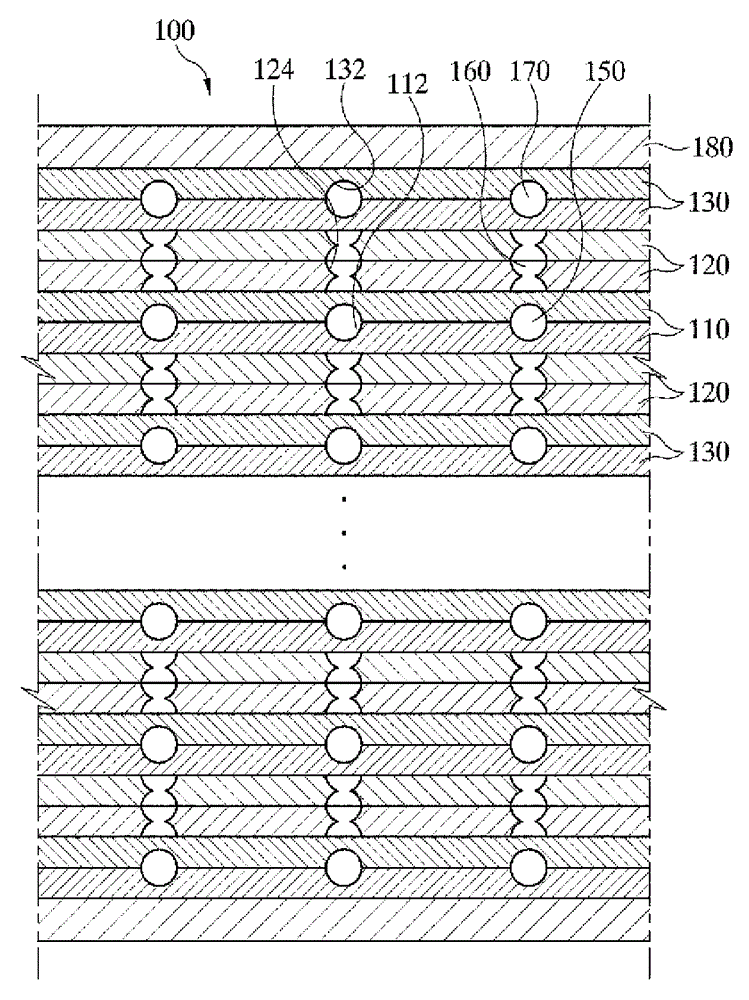

3-D channel gas heat exchanger

A heat exchanger, 3-D technology, applied in the direction of heat exchanger fixation, heat exchange equipment, indirect heat exchangers, etc., can solve the problems of insulation box size increase, heavy weight, fatigue cracking, etc., and achieve the improvement of blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. In describing the principle of operation of the exemplary embodiments of the present invention, however, when it is determined that a detailed description of a relevant function or configuration makes the subject matter of the present invention unnecessarily unclear, the detailed description will be omitted.

[0045] Also, the same reference numerals are used throughout the drawings to indicate elements having similar functions and operations. Throughout the specification, when it is described that one element is coupled with one element, the one element may be directly coupled with the other element or may be indirectly coupled with the other element through a third element.

[0046] Also, when a recited element includes any element, it means that the element does not exclude other elements, but may also include another element, unless st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com