Machine tool thermal error modeling method based on ant colony neural network

A modeling method and neural network technology, applied in the field of thermal error modeling of machine tools based on ant colony neural network, can solve the problems of falling into local extremum and long convergence time, achieve strong thermal error approximation ability, improve prediction ability, Controlling the Effect of Thermal Distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

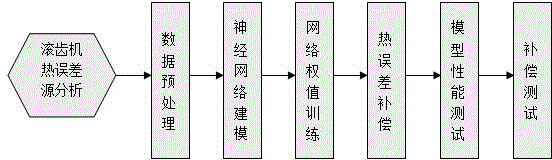

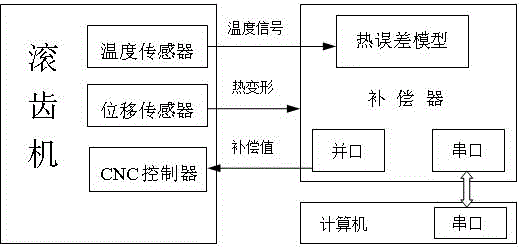

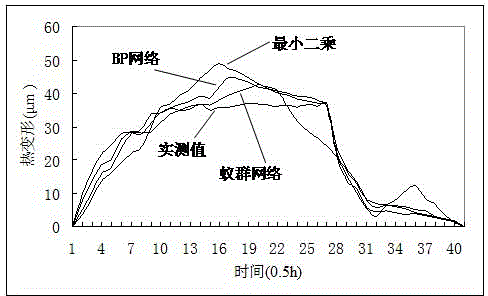

[0020] The technical flow chart of the present invention is as figure 1 As shown, the main heat source of the gear hobbing machine during processing and the influence of thermal deformation on the machining accuracy of the gear are analyzed. The measured temperature signal is used as the model input layer, and the thermal deformation error is used as the model output layer. Based on the neural network algorithm, the thermal error model of the gear hobbing machine is established. , based on the ant colony algorithm to optimize the weights in the learning process of the neural network, the ant colony neural network model is obtained. Through the self-developed thermal error compensation system, the approximation performance of the built model is verified, and the three models are applied to predict and analyze the radial thermal deformation err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com