Ash fusibility tester and standard indicating supporting plate thereof

A technology of ash fusion and tester, which is applied in the field of test equipment, can solve the problems of reducing the distance between ash cones of coal samples, affecting the test effect, and inconsistency of captured images, so as to avoid relative bending, facilitate program operation, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

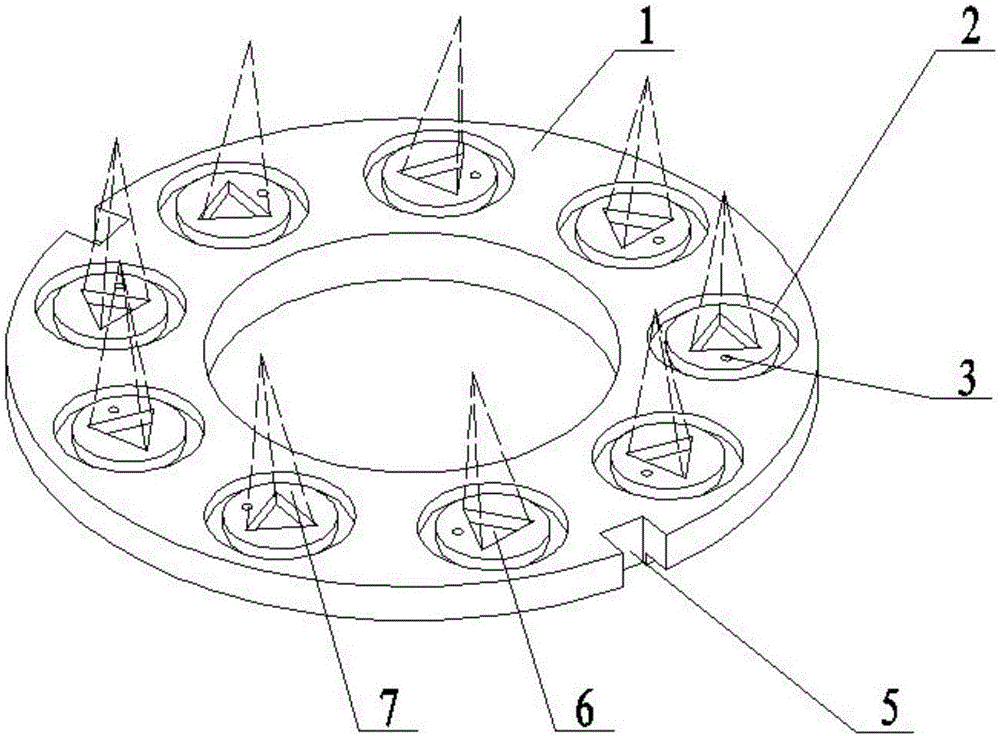

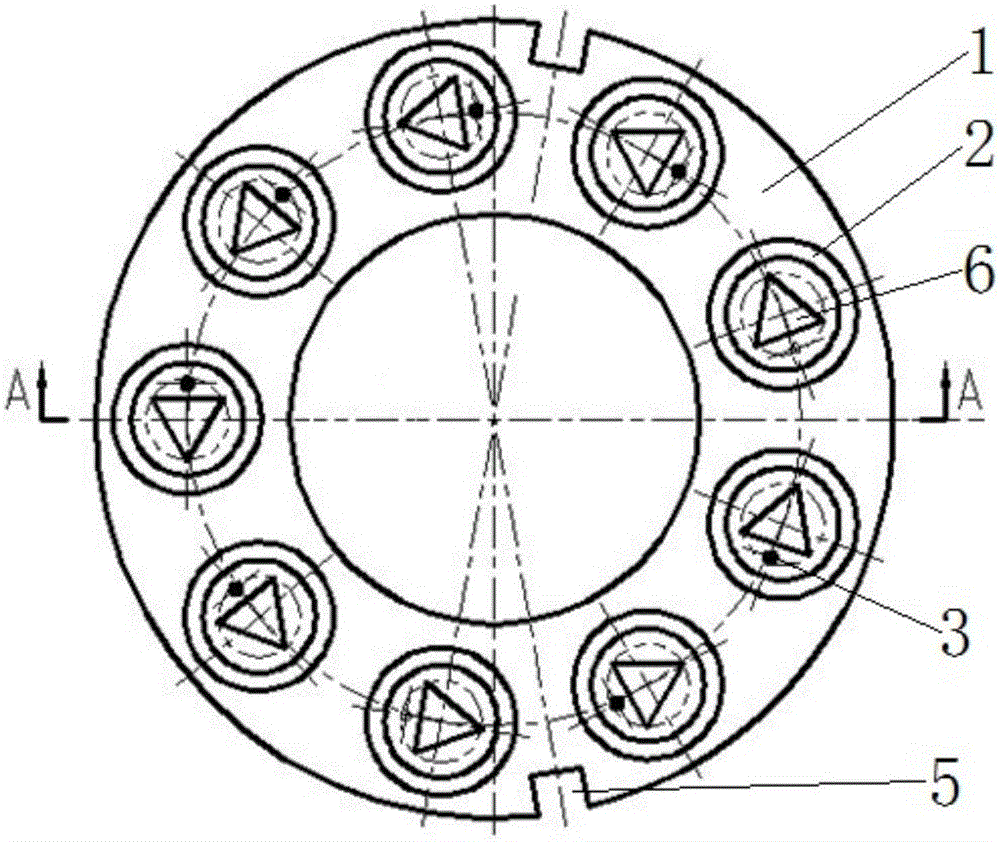

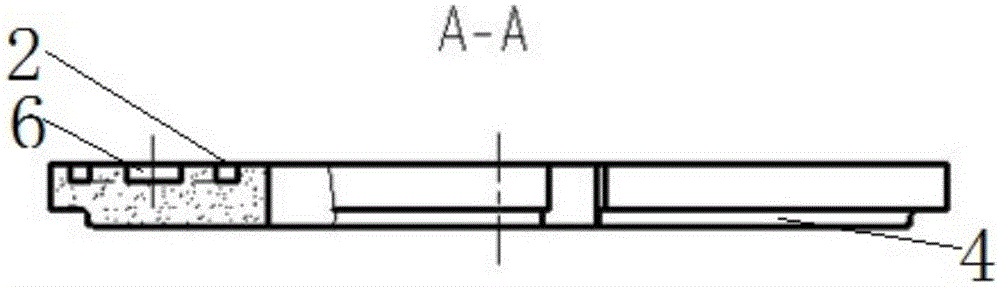

[0027] like figure 1 , figure 2 and image 3 As shown, a standard indicating pallet provided by the embodiment of the present invention includes a pallet body 1 and a plurality of ash cone holes 6 arranged on the front of the pallet body 1. The pallet body 1 is disc-shaped, and the ash cone holes 6 is an equilateral triangle blind hole, and a plurality of ash cone holes 6 are arranged in an array along the circumference of the pallet body 1, that is, the apex angles of each equilateral triangle ash cone hole 6 are in the same direction, and one of each ash cone hole 6 The outside of the corresponding side is provided with at least one position indicating point 3, which is used to indicate the elevation position of the ash cone 7 to be tested, so that the image of the ash cone 7 to be tested captured by the camera device during the test is consistent with the image preset in the picture recognition system. The images are consistent, that is, according to the preset image in ...

Embodiment 2

[0034] The technical content of the second embodiment that is the same as the first embodiment will not be described repeatedly. The content disclosed in the first embodiment also belongs to the content disclosed in the second embodiment. The difference between the second embodiment and the first embodiment is:

[0035] like Figure 4 and Figure 5 As shown, the pallet body 1 of a standard indicating pallet provided in Embodiment 2 is square, and a plurality of ash cone holes 6 are arranged in an array along a straight line, that is, the apex angles of each equilateral triangle ash cone hole 6 are directed in the same direction. . The square standard indicating support plate provided in the second embodiment is suitable for fixing the holder cup, and the ash fusion tester can shoot all the ash cones 7 to be tested at one time. A position indicator point 3 is provided on the outside of one of the corresponding sides of the ash cone hole 6 on the square standard indicator pall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com