Method for reducing tail gas suspended particles of diesel engine in sound field environment

A technology for suspended particulate matter and diesel engines, which is applied in the direction of exhaust devices, mechanical equipment, engine components, etc., and can solve problems that are not involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

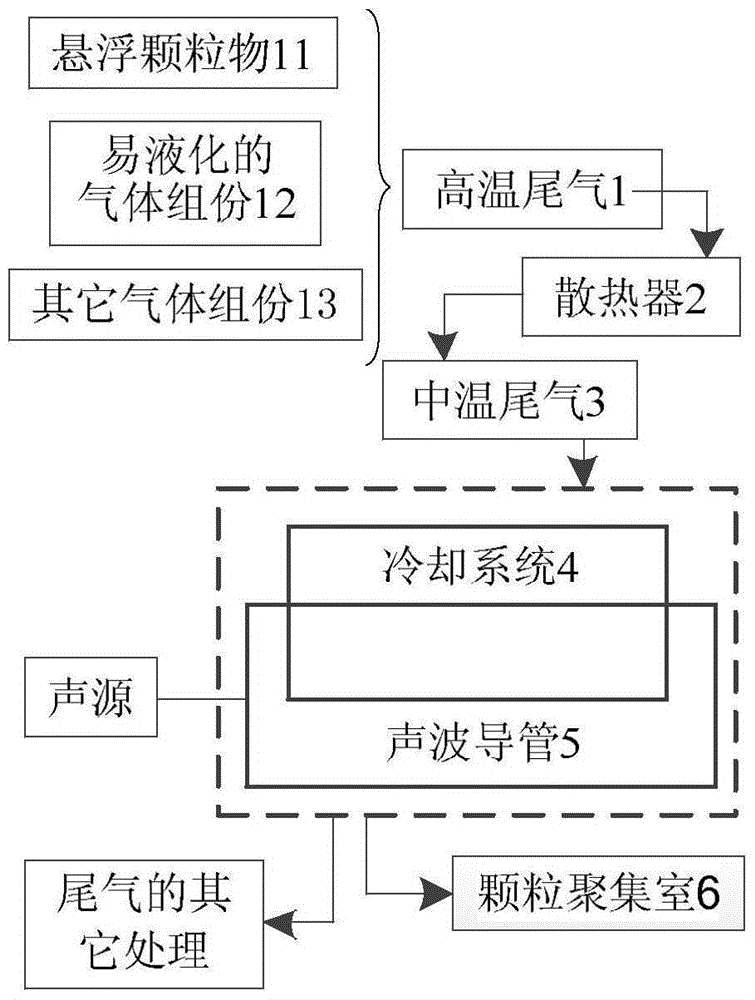

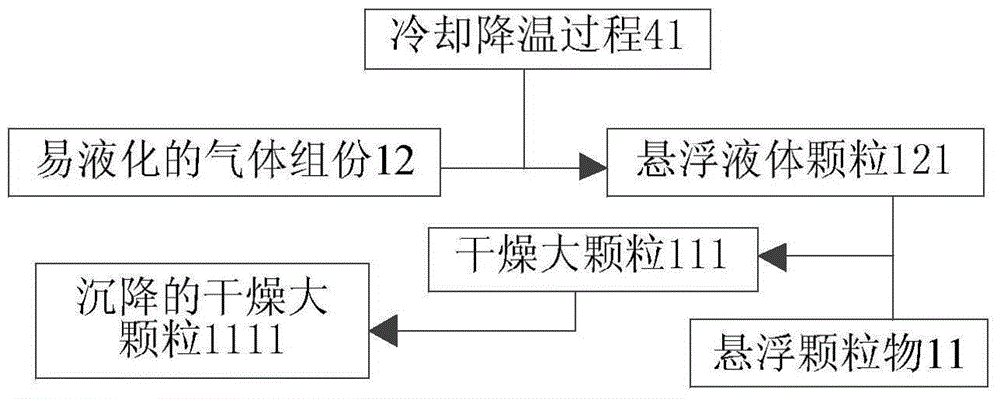

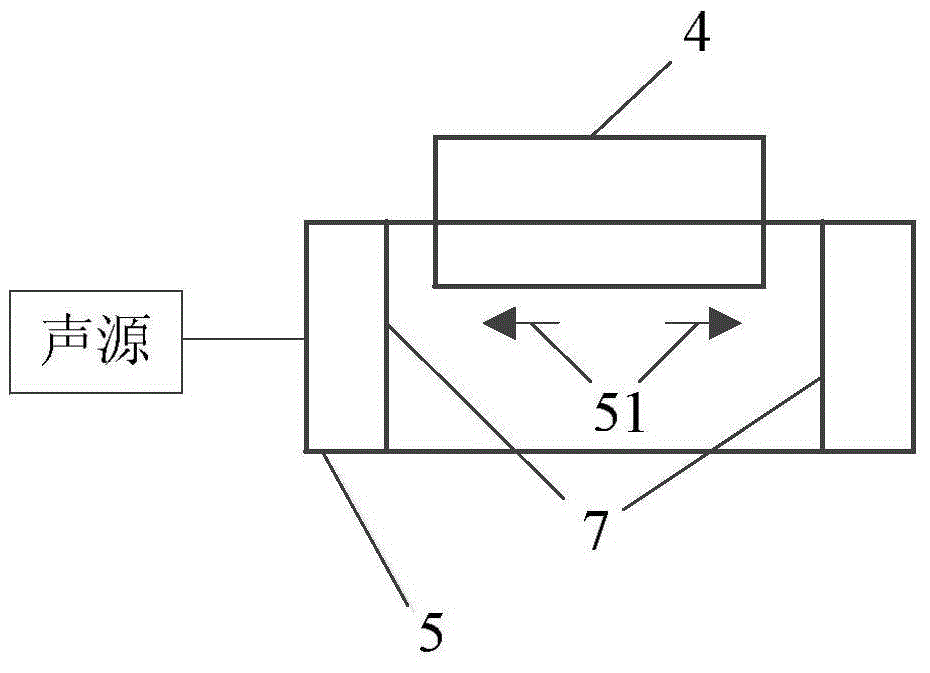

[0019] like figure 1 It is a technical schematic diagram of a method for reducing suspended particulate matter in diesel engine exhaust in a sound field environment. The high-temperature exhaust gas 1 discharged from the combustion chamber of a diesel engine includes suspended particulate matter 11, easily liquefiable gas components 12 and other gas components; the high-temperature exhaust gas 1 passes through the radiator 2. After cooling, the medium-temperature tail gas 3 becomes uncondensed. The medium-temperature tail gas 3 is introduced into the acoustic waveguide 5 coupled with the cooling system 4 and capable of generating a strong acoustic standing wave. The medium-temperature tail gas 3 is cooled and cooled. The cooling temperature is slightly lower than the dew point temperature of the easily liquefied gas component (12) in the tail gas flowing through this position, and the easily liquefied gas component 12 is liquefied into suspended liquid particles 121 with very s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com