Application of glutathione waste liquid in microorganism production and application method

A technology of glutathione and application method, applied in the field of microorganisms, can solve the problems of high capital construction investment and operation and maintenance costs, low utilization rate of waste recycling, unreported research results, etc., and achieve huge social and economic benefits. The effect of improving the quality of agricultural products and improving soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0046] 【raw material】

[0047] In September 2014, the glutathione waste liquid (that is, the centrifuged residue of the fermentation liquid produced during the production of glutathione by microbial fermentation) from Shandong Jincheng Bio-Pharmaceutical Co., Ltd. was used as raw material. Tested by the Institute of Agricultural Resources and Environment of Shandong Academy of Agricultural Sciences, its composition is: nitrogen 1.51g / 100mL; phosphorus 0.10g / 100mL; potassium 3.05g / 100mL; organic matter 40.75g / 100mL; soluble solid content 38.4g / 100mL, Sugar content 18g / 100mL, pH 5.11; moisture 54.34%.

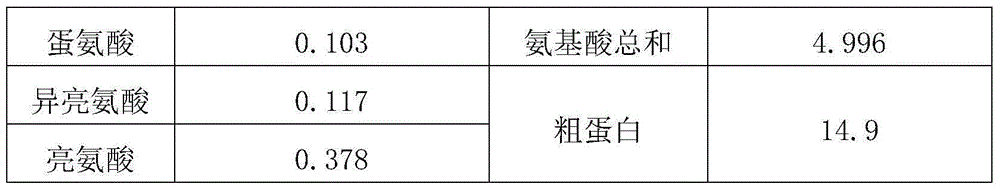

[0048] After testing by the calendar L-8900 high-speed automatic amino acid analyzer of the Urban Agriculture (North) Key Laboratory of the Ministry of Agriculture, the analysis of the 18 kinds of amino acids and crude protein content is shown in Table 1:

[0049] Analysis of 18 kinds of amino acids and crude protein content in glutathione waste liquid in table 1

[0050]

...

preparation Embodiment 2

[0069] 【raw material】

[0070] Same as Preparation Example 1.

[0071] 【Source of bacteria】

[0072] Lactobacillus acidophilus (provided in the form: ampule freeze-dried powder) was purchased from China Industrial Microorganism Culture Collection Management Center, number CICC6074).

[0073] 【Preparation of Fermentation Broth】

[0074] 1) Activation of Lactobacillus acidophilus

[0075] Slant medium preparation: 1% casein peptone, 1% beef extract, 0.5% yeast powder, 0.5% glucose, 0.5% sodium acetate, 0.2% diammonium citrate, Tween800.1%, K 2 HPO 4 0.2%, MgSO 4 ·7H 2 O0.02%, CaCO 3 2%, agar 1.5%, adjust the pH of the medium to 5.8, 121°C, 0.103MPa, sterilize for 30min, and prepare inclined test tubes under sterile conditions.

[0076] Activation method: under sterile conditions, inoculate the slant with Lactobacillus acidophilus in the cryopreservation tube, and activate it at 36°C for 36 hours to obtain the slant strain or strain slant.

[0077] 2) Preparation of Lact...

preparation Embodiment 3

[0088] 【raw material】

[0089] In December 2014, the glutathione waste liquid (that is, the centrifuged residue of the fermentation liquid produced during the production of glutathione by microbial fermentation) from Shandong Jincheng Bio-Pharmaceutical Co., Ltd. was used as raw material. Tested by the Institute of Agricultural Resources and Environment, Shandong Academy of Agricultural Sciences, its composition: nitrogen 1.53g / 100mL; phosphorus 0.097g / 100mL; potassium 3.04g / 100mL; organic matter 40.97g / 100mL; soluble solid content 38.33g / 100mL, Sugar content 17.78g / 100mL, pH 5.22; moisture 53.94%.

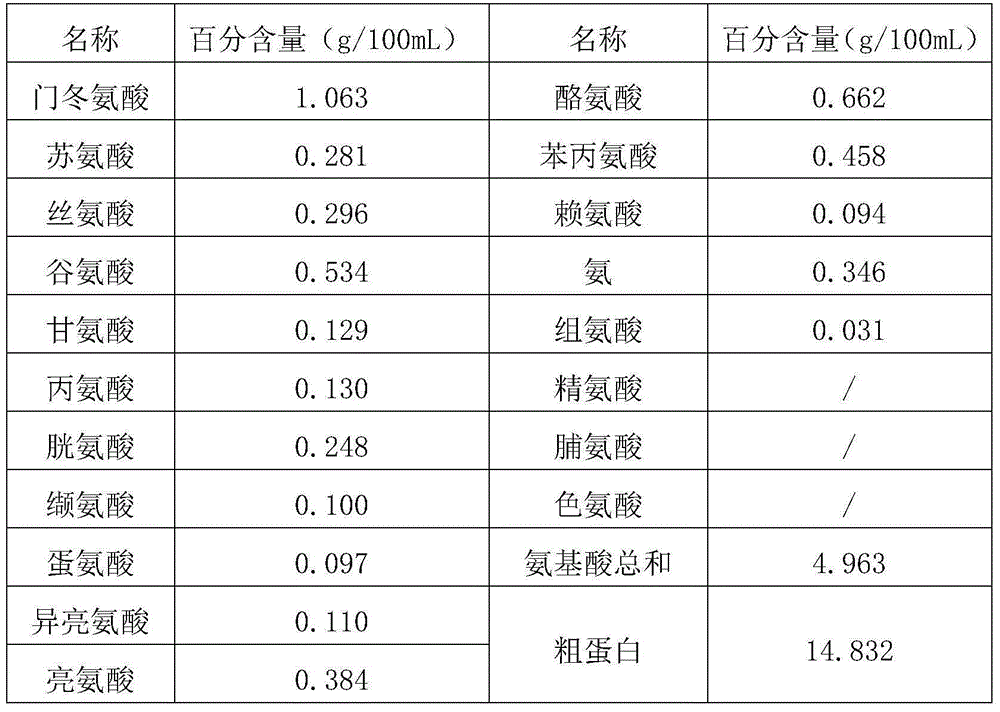

[0090] After testing by the calendar L-8900 high-speed automatic amino acid analyzer of the Urban Agriculture (Northern) Key Laboratory of the Ministry of Agriculture, the analysis of the 18 kinds of amino acids and crude protein content is shown in Table 2:

[0091] 18 kinds of amino acids and crude protein content analysis in table 2 glutathione waste liquid

[0092]

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com