Household functional paint as well as preparation method and application thereof

A technology of functional coatings and functional fillers, applied in the direction of coatings, etc., can solve the problems of easy aging and chalking of coatings, cure the symptoms but not the root cause, and low efficiency of organic matter, and achieve the effect of being suitable for storage, simple preparation and simple construction method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

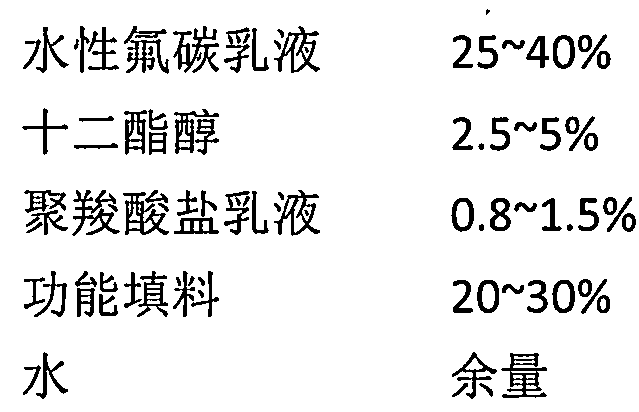

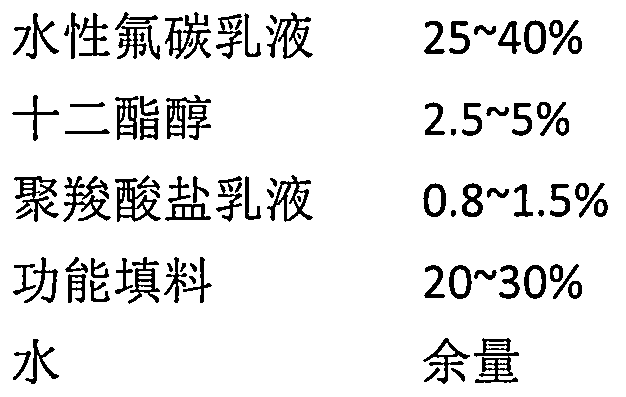

Method used

Image

Examples

Embodiment 1

[0027] Drop into water 79kg, lauryl alcohol 5kg and polycarboxylate emulsion (500 type, solid mass content 42%) 1.6kg respectively in the 500L stainless steel container, mix at low speed; Add photocatalyst (x=0.2) under low speed stirring Copper-doped bismuth vanadate, average particle size 200nm, Shanghai Huaming High-Tech Group) 10kg, then high-speed stirring 30min; Add water 26.4kg, high-speed stirring 10min; Add water-based fluorocarbon emulsion (mass solid content 45%) 50kg, low-speed Stir for 20 minutes, then filter with a 2-micron filter bag; transfer the filtered coating slurry into a 500L stainless steel container, add 28kg of porous alumina microspheres (average particle size 80nm, total pore volume 0.14mL / g, East China University of Science and Technology), and stir at a low speed After 10 minutes, household functional coating A was prepared. The viscosity of the paint at 26° C. is 114 mPa.s (DV-I digital viscometer, Brookfield Instruments).

Embodiment 2

[0029] According to the same method of embodiment, the consumption of different substances is as follows: lauryl alcohol 10kg, polycarboxylate 2kg, photocatalyst 12kg, water-based fluorocarbon emulsion 80kg, porous alumina microsphere 22kg, the coating B that makes. The paint has a viscosity of 141 mPa.s at 26°C.

Embodiment 3

[0031] According to the same method of embodiment, the consumption of different substances is as follows: lauryl alcohol 7kg, polycarboxylate 3kg, photocatalyst 21kg, aqueous fluorocarbon emulsion 56kg, porous alumina microsphere 39kg, the coating C that makes. The paint has a viscosity of 178 mPa.s at 26°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com