Preparation method of acid and alkali resistant mold silicone rubber

A silicone rubber, acid and alkali resistance technology, applied in the field of silicone rubber, can solve the problems of small shrinkage, poor acid and alkali resistance, easy demoulding, etc., to achieve improved interface bonding, improve acid and alkali resistance, and reduce acid and alkali The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

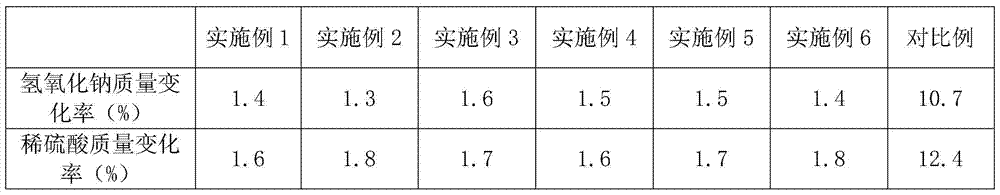

Examples

Embodiment 1

[0028] The preparation method of acid and alkali resistant mold silicone rubber, the steps are as follows:

[0029] (1) Dissolve oleic acid in ethanol and stir until completely dissolved, add deionized water and stir until uniformly dispersed to obtain a modified solution, add nano-zirconia powder to deionized water and ultrasonically disperse for 30 minutes, move to a constant temperature water bath, At the same time, the modified solution was added and stirred at 90°C for 3 hours, after aging for 24 hours, the precipitate was taken out, placed in a vacuum dryer and dried at 100°C for 2 hours, ground and sieved to obtain modified nano-zirconia, in which oleic acid, The weight ratio of nano zirconia powder is 1:4;

[0030] (2) Add 100 parts by weight of methyl vinyl phenyl silicone rubber into the open mill and mix under the condition that the roll distance is 1 mm. After wrapping, add 18 parts by weight of PTFE micropowder and 7.5 parts by weight of the modified compound obta...

Embodiment 2

[0033] The preparation method of acid and alkali resistant mold silicone rubber, the steps are as follows:

[0034] (1) Dissolve oleic acid in ethanol and stir until completely dissolved, add deionized water and stir until uniformly dispersed to obtain a modified solution, add nano-zirconia powder to deionized water and ultrasonically disperse for 30 minutes, move to a constant temperature water bath, At the same time, the modified solution was added and stirred at 90°C for 3 hours, after aging for 24 hours, the precipitate was taken out, placed in a vacuum dryer and dried at 100°C for 2 hours, ground and sieved to obtain modified nano-zirconia, in which oleic acid, The weight ratio of nano zirconia powder is 1:4;

[0035] (2) Add 100 parts by weight of methyl vinyl phenyl silicone rubber to the open mill and mix under the condition that the roll distance is 1 mm. After wrapping, add 20 parts by weight of PTFE micropowder and 7 parts by weight of the modified compound obtained...

Embodiment 3

[0038] The preparation method of acid and alkali resistant mold silicone rubber, the steps are as follows:

[0039] (1) Dissolve oleic acid in ethanol and stir until completely dissolved, add deionized water and stir until uniformly dispersed to obtain a modified solution, add nano-zirconia powder to deionized water and ultrasonically disperse for 30 minutes, move to a constant temperature water bath, At the same time, the modified solution was added and stirred at 90°C for 3 hours, after aging for 24 hours, the precipitate was taken out, placed in a vacuum dryer and dried at 100°C for 2 hours, ground and sieved to obtain modified nano-zirconia, in which oleic acid, The weight ratio of nano zirconia powder is 1:4;

[0040] (2) Add 100 parts by weight of methyl vinyl phenyl silicone rubber into the open mill and mix under the condition that the roll distance is 1 mm. After wrapping, add 16 parts by weight of PTFE micropowder and 9 parts by weight of the modified compound obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com