A carbon-coated silicon/metal/carbon nanotube negative electrode composite material and its preparation method

A technology of carbon nanotubes and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as high cost, difficult industrial production, complex process, etc., to improve electrical conductivity, Avoid pulverization and shedding, overcome the effect of low electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

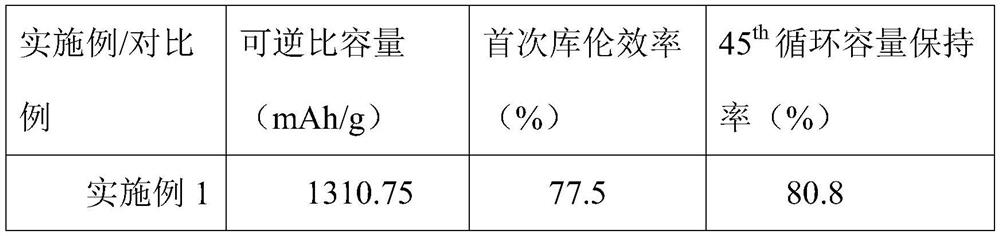

Embodiment 1

[0027] A method for preparing a carbon-coated silicon / metal / carbon nanotube negative electrode composite material, comprising the steps of:

[0028] S1. Etching the nano-silicon powder with a hydrofluoric acid solution for 6 hours to obtain porous nano-silicon;

[0029] S2, ultrasonically dispersing the porous nano-silicon obtained in step S1 in the multi-walled carbon nanotube solution, ultrasonically oscillating to disperse the carbon nanotubes in the porous silicon, adding copper nitrate, ultrasonically dispersing evenly, and standing for 2 hours to obtain a mixed solution, and The mixed solution was spray-dried at 100°C for 10 hours, and ground to obtain a composite material;

[0030] S3. Methane is passed into the composite material obtained in step S2 for step sintering, wherein the first gradient sintering temperature in step sintering is 300° C., and the time is 3 hours; the second gradient sintering temperature is 800° C., and the time is 3 hours, namely have to.

Embodiment 2

[0032] A method for preparing a carbon-coated silicon / metal / carbon nanotube negative electrode composite material, comprising the steps of:

[0033] S1. Etching the nano-silicon powder with a hydrofluoric acid solution for 6 hours to obtain porous nano-silicon;

[0034] S2, ultrasonically disperse the porous nano-silicon obtained in step S1 in the single-walled carbon nanotube solution, ultrasonically oscillate to disperse the carbon nanotubes in the porous silicon, add silver nitrate, ultrasonically disperse evenly, and let it stand for 2 hours to obtain a mixed solution. The mixed solution was spray-dried at 80°C for 10 hours, and ground to obtain a composite material;

[0035] S3. Pass ethylene into the composite material obtained in step S2 for step sintering, wherein the first gradient sintering temperature in step sintering is 200°C, and the time is 3h; the second gradient sintering temperature is 900°C, and the time is 2h, that is have to.

Embodiment 3

[0037] A method for preparing a carbon-coated silicon / metal / carbon nanotube negative electrode composite material, comprising the steps of:

[0038] S1. Etching the nano-silicon powder with a hydrofluoric acid solution for 6 hours to obtain porous nano-silicon;

[0039] S2, ultrasonically dispersing the porous nano-silicon obtained in step S1 in the multi-walled carbon nanotube solution, ultrasonically oscillating to disperse the carbon nanotubes in the porous silicon, adding silver nitrate, ultrasonically dispersing evenly, and standing for 2 hours to obtain a mixed solution, and The mixed solution was spray-dried at 120°C for 8 hours, and ground to obtain a composite material;

[0040] S3. Passing a mixed gas of acetylene and methane into the composite material obtained in step S2 for step sintering, wherein the first gradient sintering temperature in the step sintering is 400° C., and the time is 3 hours; the second gradient sintering temperature is 900° C., The time is 3h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com