Nano-copper coated porous nano silicon composite material as well as preparation method and application thereof

A composite material and nano-silicon technology, applied in the field of chemical energy storage, can solve the problems of complex process, high cost, and difficulty in mass production, and achieve the effect of overcoming low electronic conductivity, low cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

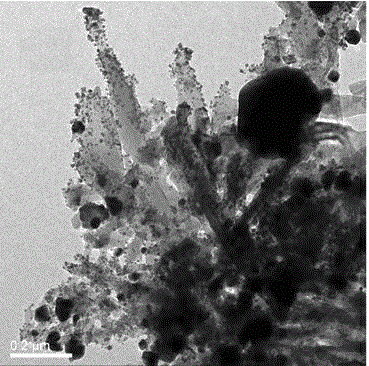

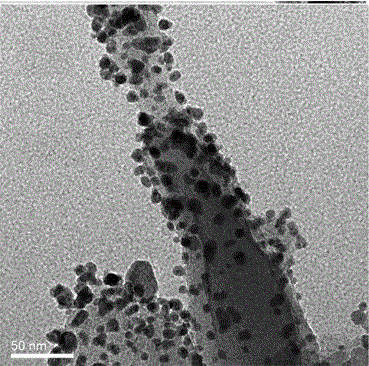

[0024] First, the porous nano-Si powder prepared by the acid etching method was plated with copper on the surface of the porous Si by an electroless copper plating method to prepare a nano-copper-coated porous nano-silicon composite material. The preparation steps are as follows: activation pretreatment, under ultrasonic conditions, the porous nano Si powder prepared by acid etching method is mixed with metal powder, such as zinc or tin metal powder, and dispersed in 0.1~20g L -1 In the silver ammonia solution or silver nitrate solution activation solution, stir slowly until the surface of the porous nano-silicon particles produces the active site Ag simple substance, and complete the activation to increase the active surface. This step is to ensure the hydrophilicity and appropriate roughness of the Si particle surface. And good coating adhesion; then, activate the pretreated porous Si powder for electroless copper plating. After filtering, washing and drying, the copper-modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com