Color masterbatch for polyolefin pipes, pipe fittings and inspection wells

A technology for polyolefin and inspection wells, which is applied in the field of color masterbatch for pipe fittings and inspection wells, and polyolefin pipes. It can solve the problems of poor dispersion, insufficient pressure resistance of pipes and pipe fittings, etc., and achieve the effect of reducing agglomeration and internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

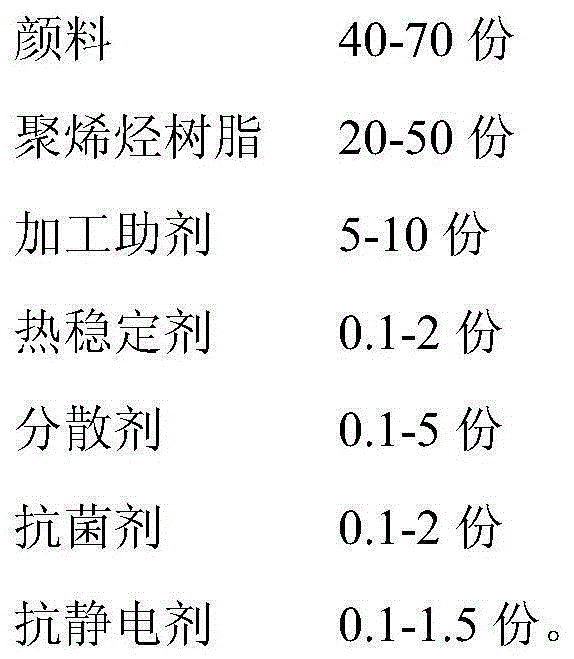

[0035] The raw material weight portion of masterbatch powder is as follows:

[0036] 40 parts of carbon black and titanium dioxide, 45 parts of PP-R grade resin, 5 parts of silane crosslinked polyethylene copolymer, 2 parts of the mixture of hindered amine antioxidant and phosphite antioxidant dispersant, titanium The mixture of ester coupling agent and aluminate coupling agent is 5 parts, vanillin is 2 parts, and ethoxylauramide is 1 part.

[0037] Its preparation method is as follows: first, weigh the above-mentioned raw materials according to the above-mentioned required weight, and then put the above-mentioned raw materials into the internal mixer for banburying, and transfer the materials after banburying to the extruder for extrusion manufacturing. Granulation, the granulated color masterbatch is air-cooled, the air-cooled material is inspected, and then the material that passes the inspection is weighed and packaged.

[0038] The functions of color masterbatch are as f...

Embodiment 2

[0041] The raw material weight portion of masterbatch powder is as follows:

[0042] 50 parts of phthalocyanine blue and phthalocyanine green mixture, 35 parts of HDPE100 grade resin, 20 parts of TGDDM, 25 parts of glass fiber, 30 parts of polypropylene, 6 parts of fluorine-free polymer processing aid, hindered phenolic antioxidant and hindered amine The mixture of antioxidants is 1 part, the polyolefin oligomer is 5 parts, the ethyl vanillin compound is 2 parts, and glycerol monostearate (GMS) is 1 part.

[0043] Its preparation method is as follows: first, weigh the above-mentioned raw materials according to the above-mentioned required weight, and then put the above-mentioned raw materials into the internal mixer for banburying, and transfer the materials after banburying to the extruder for extrusion manufacturing. Granulation, the granulated color masterbatch is air-cooled, the air-cooled material is inspected, and then the material that passes the inspection is weighed a...

Embodiment 3

[0047] The raw material weight portion of masterbatch powder is as follows:

[0048] Phthalocyanine green is 60 parts, mixture of HDPE100 grade resin and LLDPE resin is 25 parts, TGDDM is 25 parts, glass fiber is 30 parts, polypropylene is 25 parts, polyethylene graft copolymer is 8 parts, polyethylene graft copolymer is 0.5 parts, The hindered amine antioxidant is 4 parts, the vanillin is 1 part, and the ethoxylauramide is 1.5 parts.

[0049] Its preparation method is as follows: first, weigh the above-mentioned raw materials according to the above-mentioned required weight, and then put the above-mentioned raw materials into the internal mixer for banburying, and transfer the materials after banburying to the extruder for extrusion manufacturing. Granulation, the granulated color masterbatch is air-cooled, the air-cooled material is inspected, and then the material that passes the inspection is weighed and packaged.

[0050] The functions of color masterbatch are as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Thermal stabilization time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com