Polyacrylonitrile-based carbon fiber spinning solution and preparing method of polyacrylonitrile-based carbon fiber spinning solution

A polyacrylonitrile-based carbon fiber and spinning solution technology, which is applied in the fields of fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, and can solve problems such as differences in reactivity ratios and difficulties in obtaining acrylonitrile copolymers , to achieve good heat release performance, improve oxygen penetration and spinnability, and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

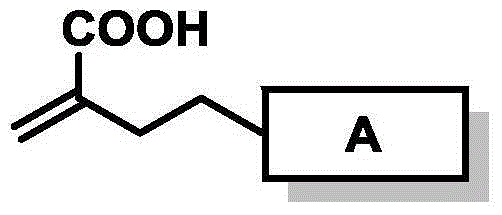

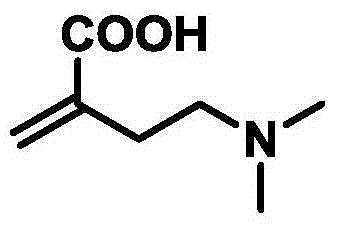

[0039] Add the initiator azobisisobutyronitrile, the main monomer acrylonitrile, the comonomer 2-methylene glutaric acid, and the solvent dimethyl sulfoxide into the reaction kettle with condensation and mechanical stirring devices. The mass percentage ratio of the added raw materials is: the main monomer acrylonitrile is 98% of the total mass of the monomer, and the comonomer 2-methylene glutaric acid is 2% of the total mass of the monomer. The mass of azobisisobutyronitrile is 0.5% of the total mass of the monomers, and the concentration of the total mass percentage of the monomers is 20%. Stir and mix at room temperature. After bubbling nitrogen for 30 minutes, react at a constant temperature of 60° C. for 24 hours under the protection of nitrogen, and then remove residual monomers and bubbles to obtain a spinning solution.

[0040]The performance test of the obtained spinning solution: the weight-average molecular weight of the copolymer is 152,000; the contact angle betwe...

Embodiment 2

[0042] Add the initiator azobisisobutyronitrile, the main monomer acrylonitrile, the comonomer 2-methylene glutaric acid, and the solvent dimethyl sulfoxide into the reaction kettle with condensation and mechanical stirring devices. The mass percentage ratio of the added raw materials is that the main monomer acrylonitrile is 97% of the total mass of the monomers, and the comonomer 2-methyleneglutaric acid is 3% of the total mass of the monomers. The mass of azobisisobutyronitrile is 0.5% of the total mass of the monomers, and the mass concentration of the monomers is 20%. Stir and mix at room temperature. After bubbling nitrogen for 30 minutes, react at a constant temperature of 60° C. for 6 hours under the protection of nitrogen, and then remove residual monomers and air bubbles to obtain a spinning solution.

[0043] The performance test of the obtained spinning solution: the weight-average molecular weight of the copolymer is 114,000; the contact angle between the copolyme...

Embodiment 3

[0045] Add the initiator azobisisobutyronitrile, the main monomer acrylonitrile, the comonomer 2-methylene glutaric acid, and the solvent dimethyl sulfoxide into the reaction kettle with condensation and mechanical stirring devices. The mass percentage ratio of the added raw materials is as follows: the main monomer acrylonitrile is 96% of the total monomer mass, and the comonomer 2-methylene glutaric acid is 4% of the total monomer mass. The mass of azobisisobutyronitrile is 0.5% of the total mass of the monomers, and the mass concentration of the monomers is 20%. Stir and mix at room temperature. After bubbling nitrogen for 30 minutes, react at a constant temperature of 60° C. for 24 hours under the protection of nitrogen, and then remove residual monomers and bubbles to obtain a spinning solution.

[0046] The performance test of the obtained spinning solution: the weight-average molecular weight of the copolymer is 118,000; the contact angle between the copolymer and water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com