Sunshade double-silver low-radiation reflective glass and preparation method therefor

A low-emissivity coating and glass technology, which is applied in the field of coated glass preparation method and the coated glass prepared by this method, can solve the problems of limited research on the production of sun-shading double-silver low-emission coated glass, high light transmittance of products, poor decoration, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

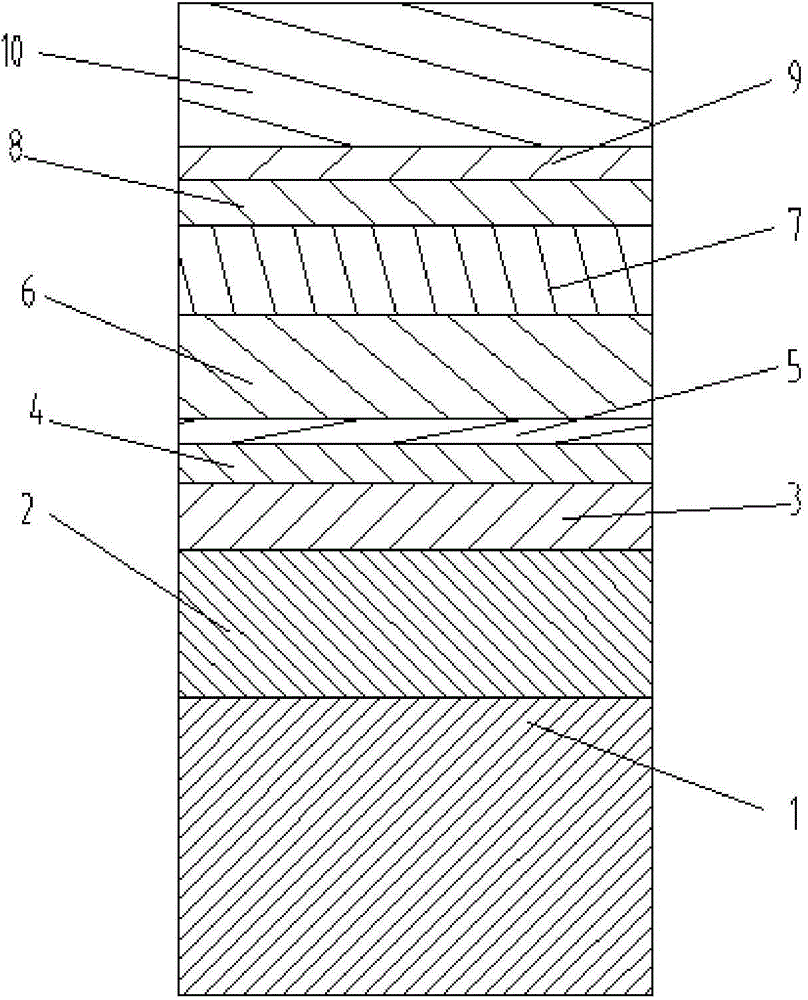

Image

Examples

Embodiment 1

[0104] 1. Target sintering

[0105] In the first to twelfth target chambers of a vacuum magnetron sputtering coating machine (Fujian Xinfuxing Glass Co., Ltd., model: XFXDM-01D), the pre-pressed targets are sintered in the first to twelfth target chambers respectively. On the corresponding target positions of the target chamber, wherein: the target materials sintered on the target positions of the first, second, sixth, seventh, eleventh, and twelfth target chambers have a sintering purity of ≥99.5% and a density of ≥ 2.1g / cm 3 1. Silicon-aluminum alloy target material with a melting point of 580°C, in which the Al content is 8-12±2wt%, and the rest is Si; the targets on the target positions of the third and eighth target rooms are sintered with a purity of ≥99.9% and a density of ≥6.9g / cm 3 , Zinc-aluminum alloy with a melting point of 410°C, in which the Al content is (2-8)±1wt%, and the rest is Zn; the targets on the target positions of the fifth and tenth target chambers ...

Embodiment 2

[0143] 1. Target sintering

[0144] Same as Example 1.

[0145] 2. Clean the glass

[0146] Except that the deionized water temperature for cleaning is 35°C, the cleaning speed is 3m / min, and the drying temperature is 45°C, all the other are the same as in Example 1;

[0147] 3. Dehumidification and degassing treatment

[0148] Except for the first dehumidification and degassing treatment, the temperature is -135°C and the absolute pressure is 6.0×10 -2 mbar; the temperature for the second dehumidification and degassing treatment is 80°C, and the absolute pressure is 6.0×10 -3 mbar, the rest are the same as in Example 1.

[0149] 4. Coating treatment

[0150] Except that the process parameters of the coating treatment are different from those in Example 1, the rest are the same as in Example 1, wherein the process parameters of the coating treatment are shown in Table 2.

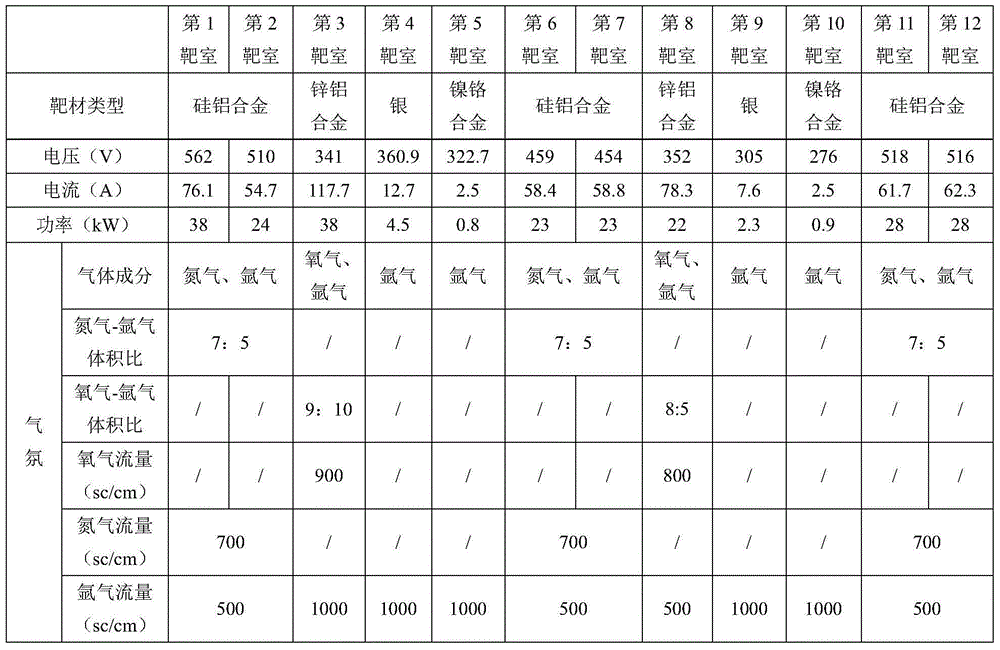

[0151] Table 2 embodiment 2 process parameter list of coating treatment

[0152]

[0153]

...

Embodiment 3

[0159] 1. Target sintering

[0160] Same as Example 1.

[0161] 2. Clean the glass

[0162] Except that the deionized water temperature for cleaning is 40°C, the cleaning speed is 5m / min, and the drying temperature is 55°C, all the other are the same as in Example 1;

[0163] 3. Dehumidification and degassing treatment

[0164] Except that the temperature of the first dehumidification and degassing treatment is -145°C, the temperature of the second dehumidification and degassing treatment is 100°C, and the absolute pressure is 3.0×10 -3 mbar, the rest are the same as in Example 1.

[0165] 4. Coating treatment

[0166] Except that the process parameters of the coating treatment are different from those of Example 1, the rest are the same as those of Example 1, wherein the process parameters of the coating treatment are shown in Table 3.

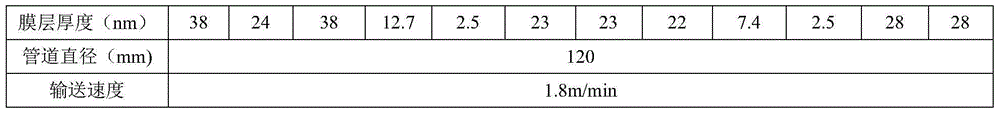

[0167] Table 3 embodiment 3 process parameter list of coating treatment

[0168]

[0169] 5. Buffering

[0170] Same as Example 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com