Treatment method and system of nickel-containing wastewater conforming to Water Pollutant Table III Discharge Standard

A technology for discharge standards and water pollutants, which is applied in the fields of water pollutants, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Table 3: Requirements for special discharge limits of water pollutants, etc., to achieve the effect of simple and convenient operation and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

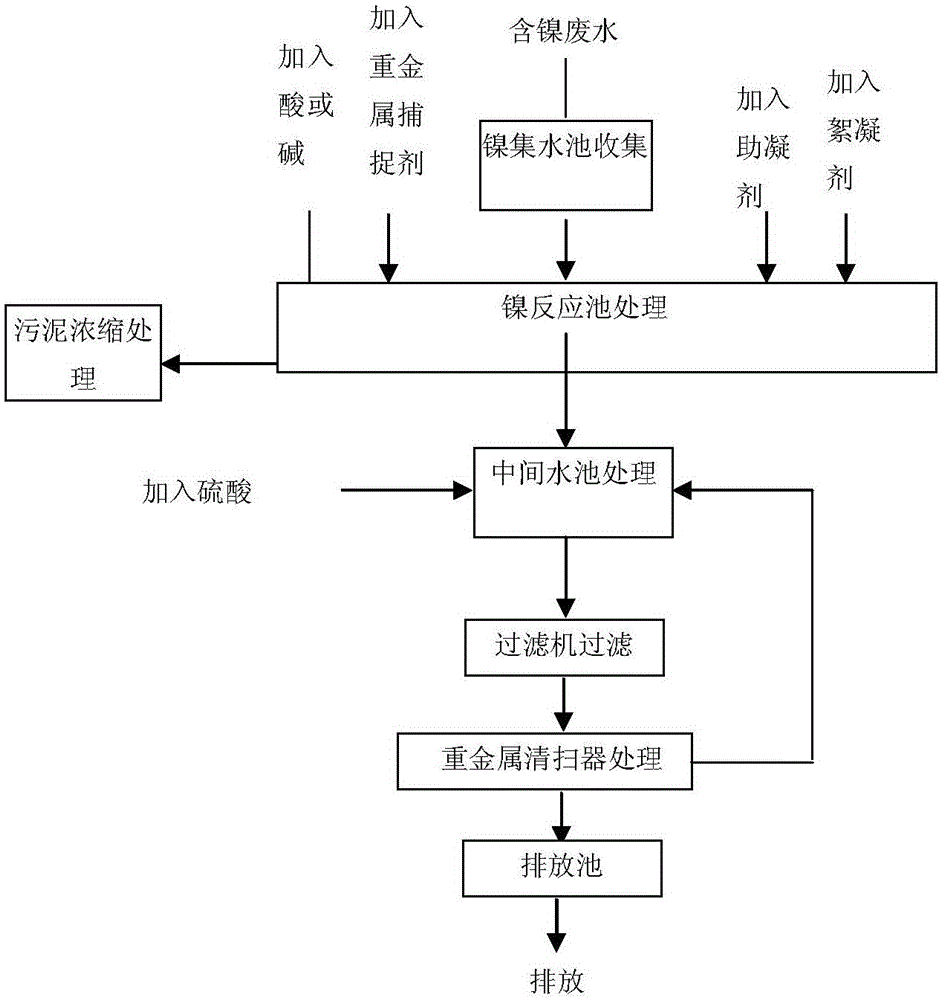

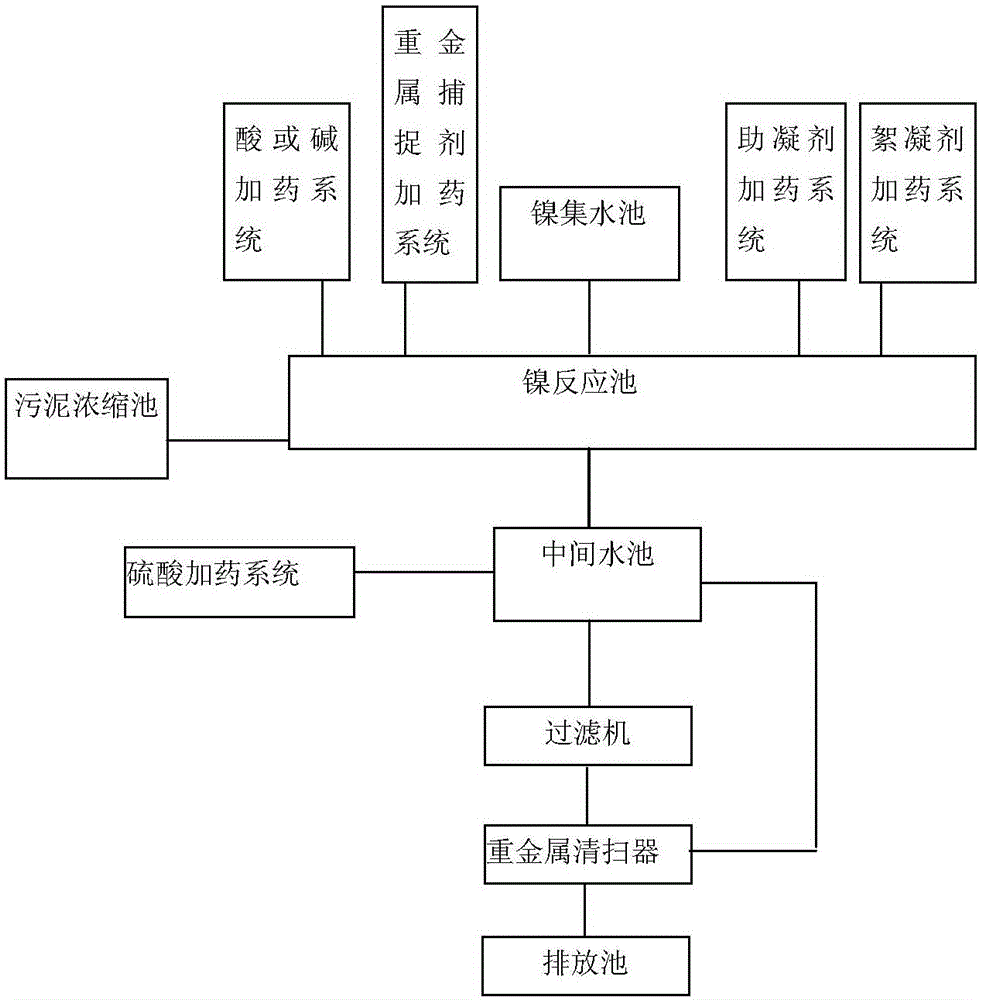

[0045] The nickel-containing wastewater (without chemical nickel) from a nickel-plating production line of a certain factory enters the nickel sump. The nickel concentration is 285.6mg / L and the pH is 3.2. Use a pump to pump into the nickel reaction tank, and use the automatic dosing system to automatically add a mixture of sodium hydroxide: calcium hydroxide (weight ratio 1:1) to the wastewater in the nickel reaction tank, adjust the pH value of the wastewater to 9.5, and mix well Finally, add 500mg / L of heavy metal scavenger, after fully bubbling and stirring for 10 minutes, add 300mg / L of polyaluminum chloride, add 5mg / L of cationic polyacrylamide after bubbling and stirring for 3 minutes, and statically precipitate for 2 hours. The detection supernatant nickel ion concentration is 0.186mg / L, and pH value is 9.2. The supernatant enters the intermediate tank, and the sludge enters the sludge thickening tank. The automatic dosing system is used to automatically add 5% sulfur...

Embodiment 2

[0047] The nickel-containing wastewater (without chemical nickel) from a nickel-plating production line of a certain factory enters the nickel sump. The nickel concentration is 98.4mg / L and the pH is 12.5. Use a pump to pump into the nickel reaction tank, use the automatic dosing system to automatically add 5% sulfuric acid solution to the nickel reaction tank wastewater, adjust the pH value of the wastewater to 10.5, add 100mg / L of heavy metal scavenger after mixing evenly, and fully drum Add 100mg / L polyaluminum ferric chloride after bubbling and stirring for 15 minutes, add 15mg / L cationic polyacrylamide after bubbling and stirring for 3 minutes, and settle for 2.5 hours. The nickel ion concentration in the supernatant is 0.155mg / L , PH value is 9.8. The supernatant enters the intermediate tank, and the sludge enters the sludge thickening tank. The automatic dosing system is used to automatically add 5% sulfuric acid solution to the water in the middle pool, adjust the pH ...

Embodiment 3

[0049] The nickel-containing wastewater (without chemical nickel) from a nickel-plating production line of a certain factory enters the nickel sump. The nickel concentration is 156.2mg / L and the pH is 2.8. Use a pump to pump into the nickel reaction tank, and use the automatic dosing system to automatically add a mixture of sodium hydroxide: calcium hydroxide (weight ratio 1:1) to the wastewater in the nickel reaction tank, adjust the pH value of the wastewater to 9.8, and mix well Then add 200mg / L heavy metal scavenger, after fully bubbling and stirring for 10 minutes, add 150mg / L ferrous sulfate, add 10mg / L cationic polyacrylamide after bubbling and stirring for 3 minutes, static precipitation for 2.5 hours, and detect The nickel ion concentration of the supernatant was 0.205mg / L, and the pH value was 9.6. The supernatant enters the intermediate tank, and the sludge enters the sludge thickening tank. The automatic dosing system is adopted to automatically add 5% sulfuric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com