Non-phosphorus scale and corrosion inhibitor containing fulvic acid and preparation method thereof

A technology of phosphorus-free scale inhibition and fulvic acid, applied in chemical instruments and methods, scale removal and water softening, water/sludge/sewage treatment, etc., can solve water source pollution, low scale and corrosion inhibition rates, and inability to Biodegradation and other issues, to achieve the effect of reducing environmental pollution, good stability, high flocculation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

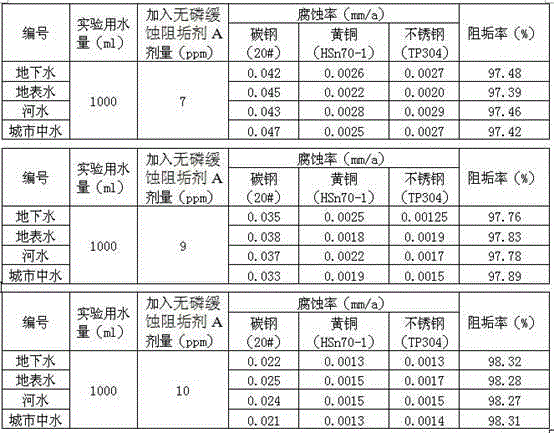

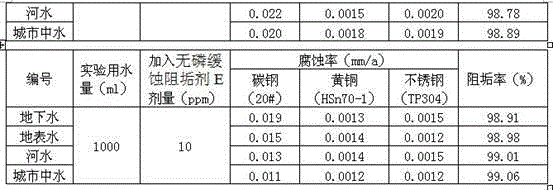

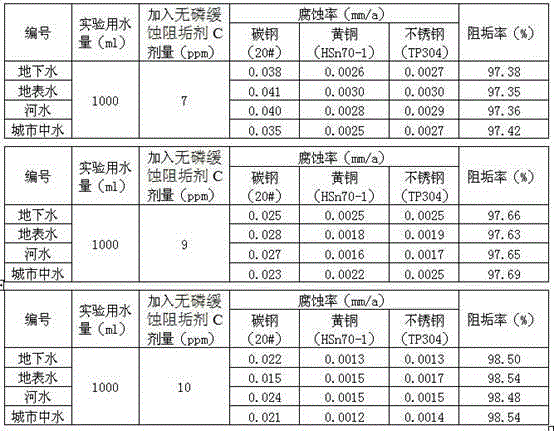

Embodiment 1

[0032] A preparation method of a phosphorus-free scale and corrosion inhibitor containing fulvic acid, the specific operation steps are as follows:

[0033] step 1,

[0034] Weigh 300g of scale inhibitor components, 300g of corrosion inhibitor components and 400g of deionized water;

[0035] Wherein, the antiscalant component of 300g is made up of the fulvic acid of 27% by mass percentage, the maleic acid-acrylic acid binary copolymer of 28%, the polyaspartic acid of 45%;

[0036] The corrosion inhibitor component of 300g is made up of the zinc sulfate of 30% by mass percentage, the imidazoline of polyoxyethylene naphthenate of 70%;

[0037] Step 2,

[0038] Add zinc sulfate to deionized water, stir fully to completely dissolve zinc sulfate, and obtain mixture A;

[0039] Step 3,

[0040] Add fulvic acid to mixture A and stir well to obtain mixture B;

[0041] Step 4,

[0042] Add maleic acid-acrylic acid binary copolymer and polyaspartic acid successively to mixture B, ...

Embodiment 2

[0070] A preparation method of a phosphorus-free scale and corrosion inhibitor containing fulvic acid, the specific operation steps are as follows:

[0071] step 1,

[0072] Weigh 500g of scale inhibitor component, 400g of corrosion inhibitor component and 100g of deionized water;

[0073] Wherein, the antiscaling component of 500g is made up of the fulvic acid of 40% by mass percentage, the maleic acid-acrylic acid binary copolymer of 30%, the polyaspartic acid of 30%;

[0074] The corrosion inhibitor component of 300g is made up of the zinc sulfate of 40% by mass percentage, the imidazoline of polyoxyethylene naphthenate of 60%;

[0075] Step 2,

[0076] Add zinc sulfate to deionized water, stir fully to completely dissolve zinc sulfate, and obtain mixture A;

[0077] Step 3,

[0078] Add fulvic acid to mixture A and stir well to obtain mixture B;

[0079] Step 4,

[0080] Add maleic acid-acrylic acid binary copolymer and polyaspartic acid successively to mixture B, st...

Embodiment 3

[0107] A preparation method of a phosphorus-free scale and corrosion inhibitor containing fulvic acid, the specific operation steps are as follows:

[0108] step 1,

[0109] Weigh 200g of scale inhibitor components, 150g of corrosion inhibitor components and 650g of deionized water;

[0110] Wherein, the antiscaling component of 200g is made up of the fulvic acid of 25% by mass percent, the maleic acid-acrylic acid binary copolymer of 20%, the polyaspartic acid of 55%;

[0111] The corrosion inhibitor component of 300g is made up of the zinc sulfate of 55% by mass percentage, the imidazoline of polyoxyethylene naphthenate of 45%;

[0112] Step 2,

[0113] Add zinc sulfate to deionized water, stir fully to completely dissolve zinc sulfate, and obtain mixture A;

[0114] Step 3,

[0115] Add fulvic acid to mixture A and stir well to obtain mixture B;

[0116] Step 4,

[0117] Add maleic acid-acrylic acid binary copolymer and polyaspartic acid successively to mixture B, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com