A sorting method for rough coal slime with disturbed bed dense medium cyclone for selection of refractory coarse coal

A heavy medium cyclone and interference bed technology, applied in chemical instruments and methods, flotation, solid separation, etc., can solve problems such as reasonable recovery of unfavorable coarse slime resources, small differences in interference settling velocity, and loss of technical and economic benefits. , to achieve the effect of improving sorting accuracy and sorting efficiency, low operating cost and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

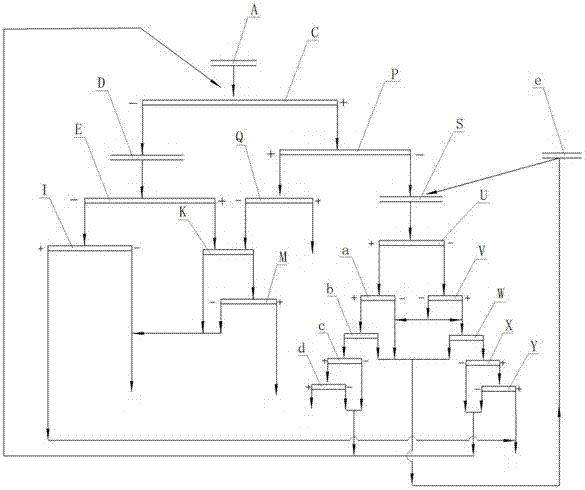

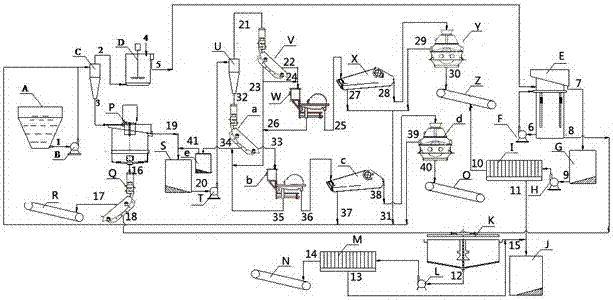

[0026] Such as figure 1 and figure 2 As shown, the separation method of rough coal slime dense medium cyclone for rough separation of disturbed bed, including the coal slime in coal slime bucket A enters into hydraulic grading cyclone C, and hydraulic grading cyclone C After classification, the overflow enters the slurry preprocessor D, and after treatment, it enters the flotation column E for flotation to obtain flotation clean coal and flotation tailings. After classification by the hydroclassifying cyclone C, the underflow enters the interference bed separator P Carry out rough separation to obtain coarse fine coal slime and tailing coal slime; the coarse fine coal slime sorted by the disturbed bed separator P and the qualified medium in the qualified medium tank e enter the mixing tank S, and after mixing, put into the heavy coal slime Clean coal and middling coal ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com