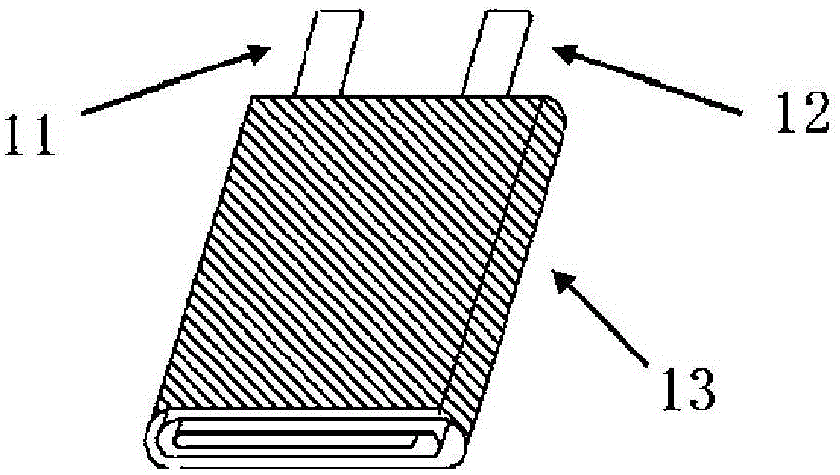

Lithium-ion cell

A lithium-ion battery and lithium metal film technology, which is applied to lithium batteries, secondary batteries, battery electrodes, etc., can solve the problem that the battery capacity cannot reach the expected value, achieve no leakage test defects, suppress internal short circuits, and have excellent cycle characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

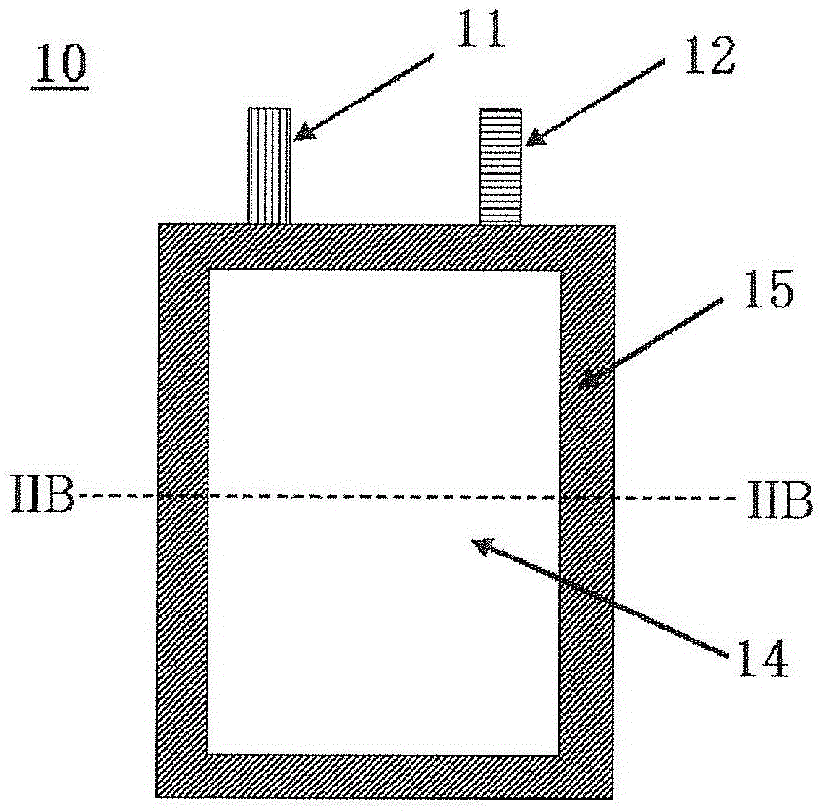

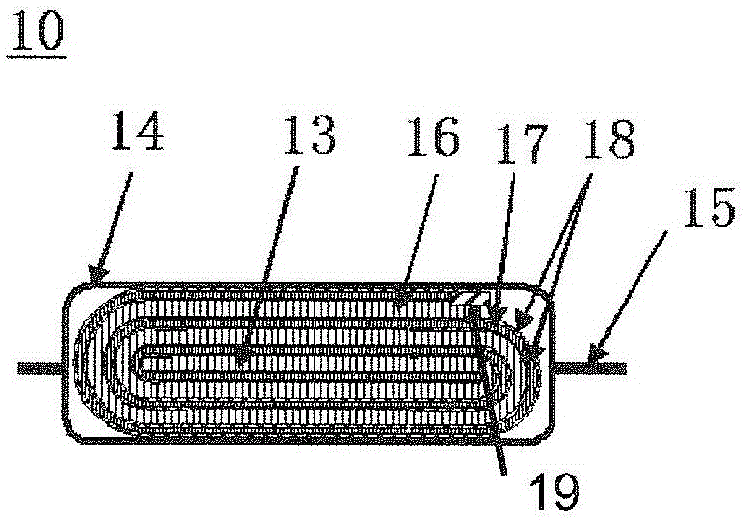

[0023] The lithium ion battery of Experimental Example 1 was fabricated as follows.

[0024] (production of positive electrode)

[0025] The lithium cobalt composite oxide (LiCoO 2 ) 100 parts by mass, 1.5 parts by mass of acetylene black, 1.5 parts by mass of polyvinylidene fluoride and an appropriate amount of N-methylpyrrolidone (NMP) were mixed together in a mixer to prepare a positive electrode mixture slurry.

[0026] This positive electrode mixture slurry is applied to both sides of a positive electrode current collector sheet made of Al foil with a thickness of 15 μm, dried, and cut into a battery case made of a predetermined laminate material after rolling. Corresponding size, thereby obtaining the positive electrode used in the lithium-ion battery of Experimental Example 1. The charge capacity of the positive electrode is 3.6mAh / cm 2 .

[0027] (production of negative electrode)

[0028] The average particle size (D 50 ) 10 parts by mass of SiO particles of 6 μ...

experiment example 2

[0038] The lithium ion battery of Experimental Example 2 has the same configuration as that of Experimental Example 1, except that the insulating tape 19 is not attached, and the separator formed with a lithium metal film is formed around one more turn.

experiment example 3

[0040] As the lithium ion battery of Experimental Example 3, except that the insulating tape 19 was not pasted on the positive electrode current collector, and the lithium metal film was removed from the end surface of the outermost periphery of the separator, the same structure as that of Experimental Example 1 was produced. constitute.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com