Silicon-carbon composite material, preparation method and application thereof

A technology of silicon-carbon composite materials and composite materials, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of silicon expansion, poor material cycle performance, and serious silicon agglomeration, etc., to improve electrical conductivity , stable charging and discharging speed, uniform path length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

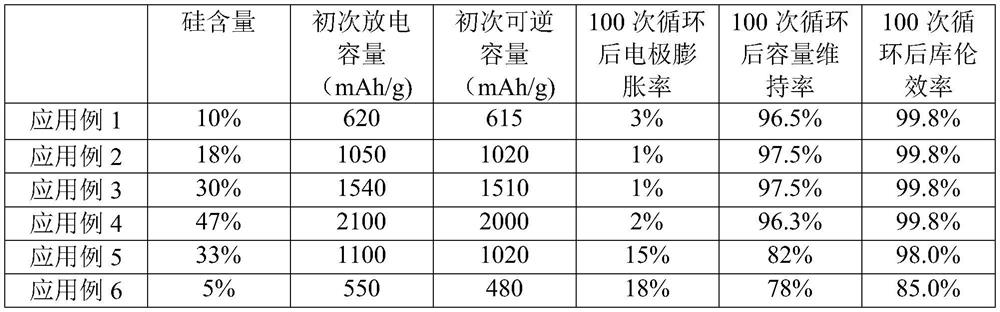

Examples

Embodiment 1

[0047] Get 100g microspherical phenolic resin-based activated carbon (its source is: Jinan Jingzhi Founder New Material Co., Ltd. PF-7001, D50=3 micron, specific surface area 600m 2 / g, the macropore content is less than 5%, the mesopore volume content is 11%, and the sphericity is 0.8. Put it into a rotary furnace, and heat it up to 500 °C at a rate of 5 °C / min under the protection of 1.0 L / min high-purity nitrogen. After holding for 2 hours, switch high-purity nitrogen to high-purity SiH 4 The gas was kept at a flow rate of 2 L / min for 1 hour, then switched back to high-purity nitrogen protection, and naturally cooled to room temperature to prepare 105 g of silicon-carbon composite microspheres.

Embodiment 2

[0049] Get 100g microspherical phenolic resin-based activated carbon (its source is: Jinan Jingzhi Founder New Material Co., Ltd. PF-7001, D50=3 micron, specific surface area 1800m 2 / g, the mesopore volume content is 20%, the macropore volume content is less than 5%, and the sphericity is 0.8. Put it into a rotary furnace, and heat it up to 500 °C at a rate of 5 °C / min under the protection of 1.0 L / min high-purity nitrogen. After holding for 2 hours, switch high-purity nitrogen to high-purity SiH 4 The gas was kept at a flow rate of 2 L / min for 2 hours, then switched to high-purity nitrogen protection, and naturally cooled to room temperature to prepare 112 g of silicon-carbon composite microspheres.

Embodiment 3

[0051] Get 100g microspherical phenolic resin-based activated carbon (its source is: Jinan Jingzhi Founder New Material Co., Ltd. PF-7001, D50=3 micron, specific surface area 1940m 2 / g, the mesopore volume content is 26%, the macropore volume content is less than 5%, and the sphericity is 0.8) is put into the rotary furnace, under the protection of 1.0L / min high-purity nitrogen, the temperature is raised to 500°C at a speed of 5°C / min, After holding for 2 hours, switch high-purity nitrogen to high-purity SiH 4 The gas was kept at a flow rate of 2 L / min for 3 hours, then switched to high-purity nitrogen protection, and naturally cooled to room temperature to prepare 124 g of silicon-carbon composite microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com