A method for recovering graphite from scrapped lithium-ion batteries

A lithium-ion battery, graphite technology, applied in battery recycling, waste collector recycling, battery electrodes, etc., can solve the problem of less full battery powder involved, and achieve excellent stability, low cost and energy consumption, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

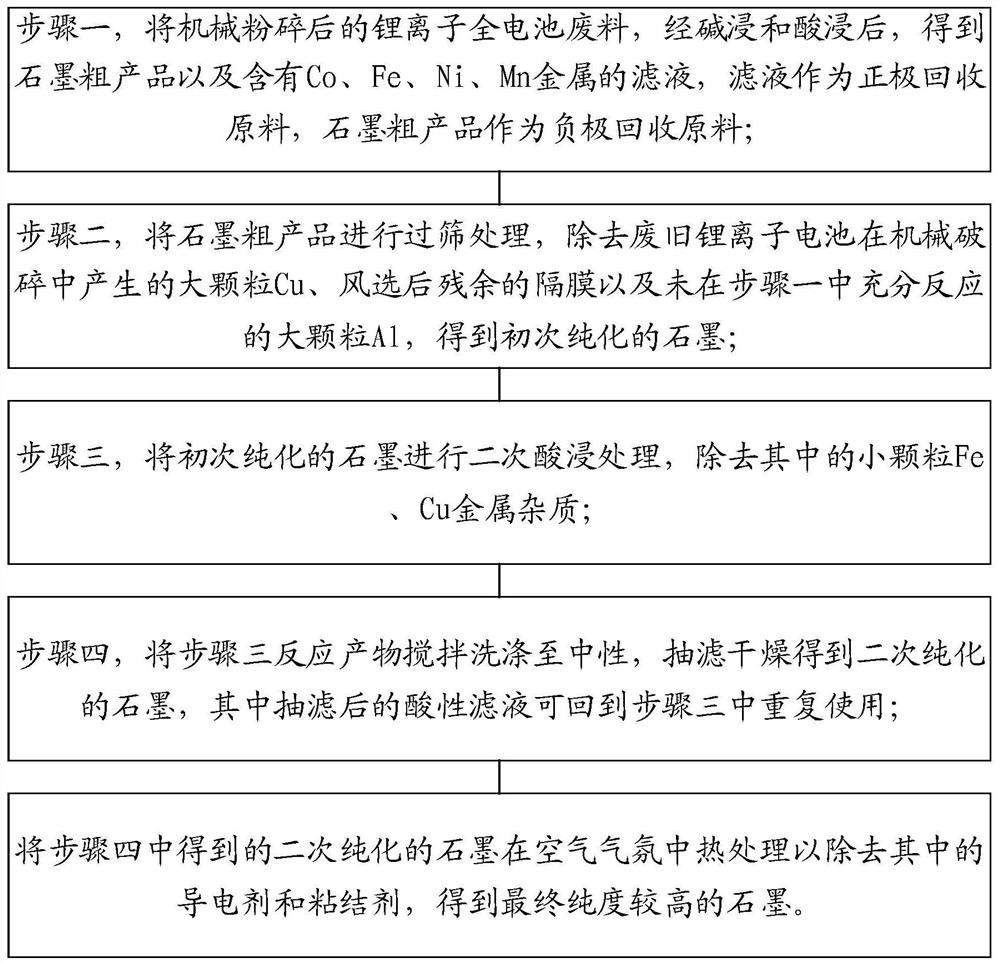

Method used

Image

Examples

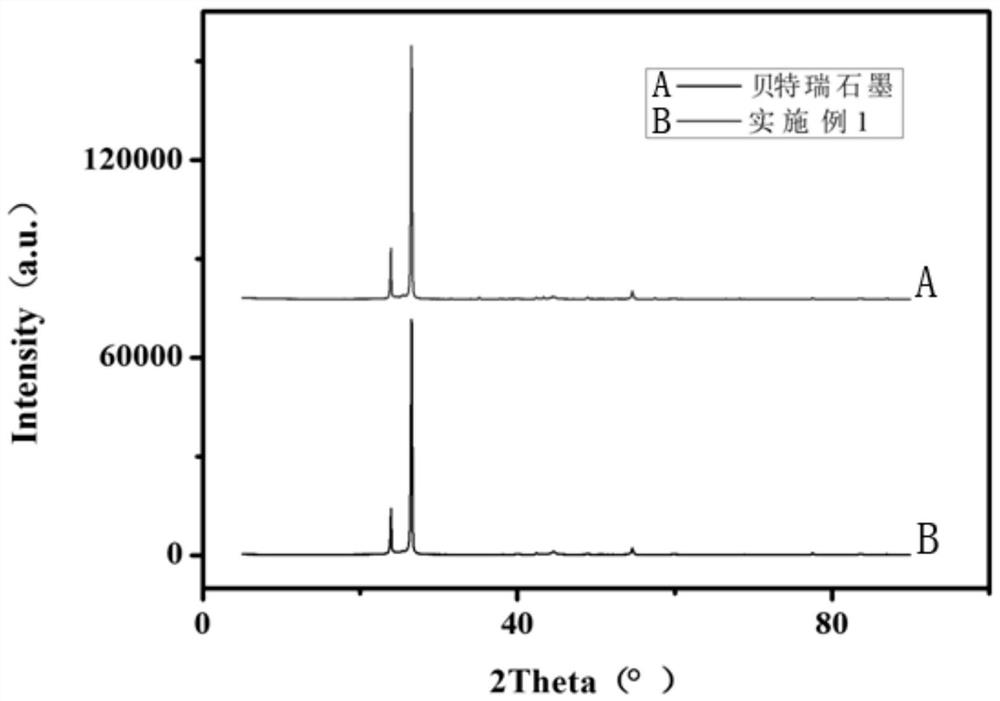

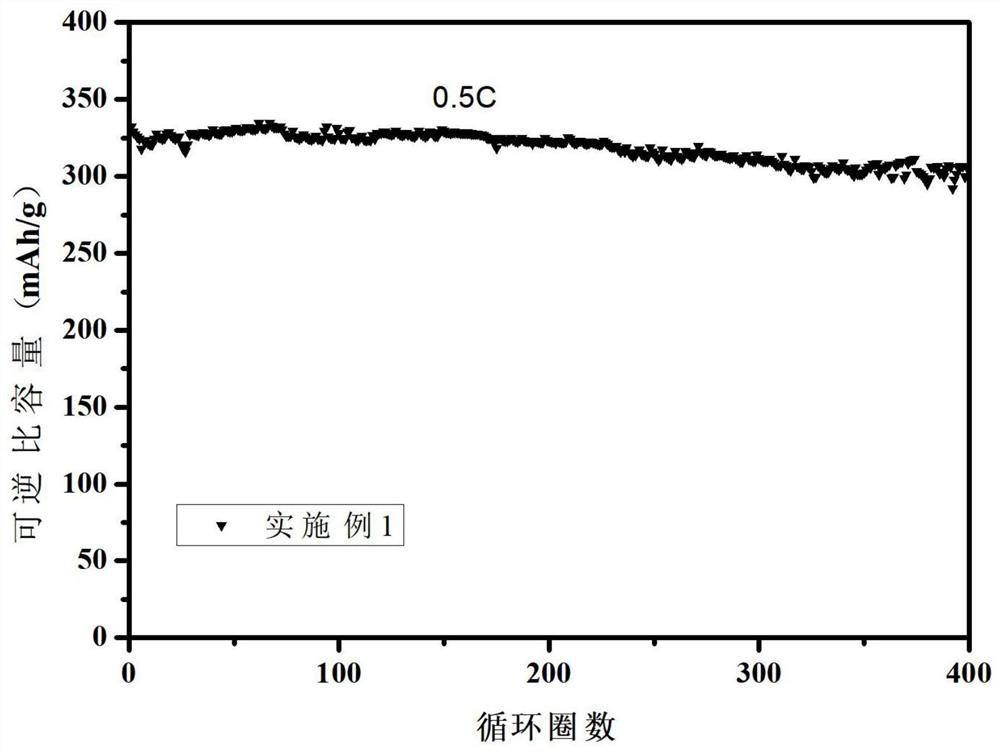

Embodiment 1

[0035] In this example, LCO||graphite scrap battery waste was used as raw material to explore different secondary acid leaching processes (including different solid-liquid ratios, different acid concentrations, different reaction temperatures and reaction times), and different heat treatment processes. Take the optimal acid concentration process as an example: the acid is hydrochloric acid, the concentration is 5mol / L, the solid-liquid ratio is 1g / 5ml, the acid leaching reaction temperature is 50°C, and the acid leaching time is 2h. The heat treatment temperature is 550°C, and the heat treatment time is 2h. The recovery methods of other processes are the same.

[0036] Step 1, using the scrapped full battery waste of LCO||graphite after mechanical crushing as raw material, through NaOH alkali leaching and acid leaching, and suction filtration to obtain acid leaching solution and graphite crude product, which contains a large amount of metal elements such as Co and Li The filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com