Method for producing deep ultraviolet laser light through visible laser direct frequency conversion and all-solid-state deep ultraviolet laser

A direct laser and deep ultraviolet technology, applied in the laser field, can solve the problems of complex light source steps and low conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

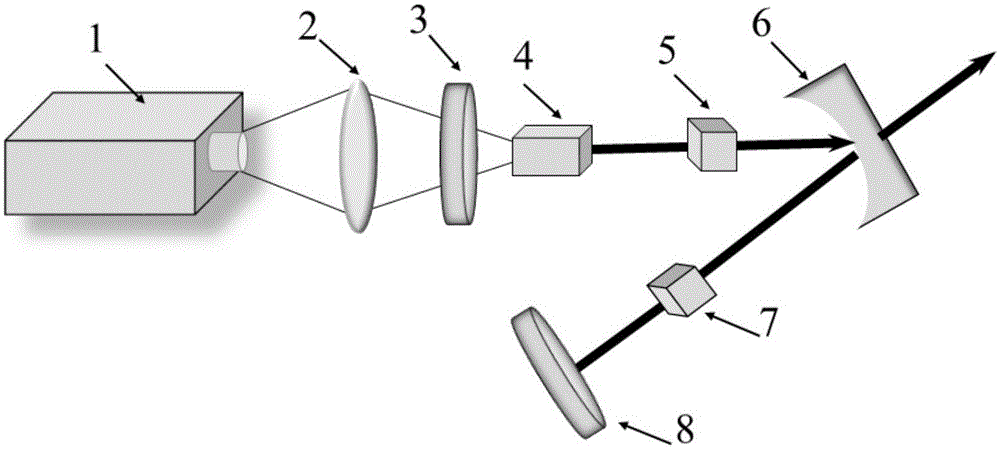

[0045] Example 1: An all-solid-state deep ultraviolet laser and deep ultraviolet laser generation method based on BBO and KBBF frequency doubling crystals

[0046] All-solid-state deep ultraviolet laser structure such as figure 1 As shown, the device includes a pump source 1 , a focusing system 2 , an input mirror 3 , a laser gain medium 4 , a double frequency crystal 5 , a plano-concave output mirror 6 , a frequency triple crystal 7 and a flat mirror 8 . Among them, the frequency doubling crystal is the frequency doubling crystal β-BaB used in the ultraviolet band 2 o 4 (BBO), the thickness of the BBO crystal in the direction of light transmission is 0.5mm, the end face of the BBO crystal is polished without coating, and the BBO crystal is cut and processed according to the phase θ ooe =35°~23°, Matching angles are made.

[0047] The frequency tripled crystal 7 is KBe that can be used in the deep ultraviolet band 2 BO 3 f 2 Crystal (KBBF). Adopt the existing prism co...

Embodiment 2

[0051] As described in Embodiment 1, the difference is that the concave surface of the plano-concave output mirror 6 is coated with a dielectric film with a partial reflection of 150-250nm and a reflectivity of 95%-99%, and a high reflection of 550-620nm. For 620-750nm anti-reflection dielectric film (to suppress 620-750nm wavelength laser output), its plane is coated with 150-250nm anti-reflection dielectric film. The flat mirror 8 is coated with a dielectric film with high reflection of 150-250nm. The visible fundamental frequency light generated by the blue LD pump laser gain medium passes through the double frequency crystal to generate double frequency ultraviolet laser, and the remaining visible fundamental frequency light reaches the deep ultraviolet frequency double crystal through the plano-concave output mirror, and the deep ultraviolet double The frequency crystal 7 is placed in a vacuum device, and the 201nm deep ultraviolet laser is output from the flat-concave ou...

Embodiment 3

[0052] Embodiment 3: As described in Embodiment 1, the difference is: wherein, the concave surface of the plano-concave output mirror 6 is plated with a dielectric film between 150-250nm partial reflection and a reflectivity of 95%-99%, for 600- 650nm highly reflective dielectric film, its plane is coated with 150-250nm anti-reflection dielectric film. The flat mirror 8 is coated with a dielectric film with high reflection of 150-250nm. The visible fundamental frequency light generated by the blue LD pump laser gain medium passes through the double frequency crystal to generate double frequency ultraviolet laser, and the remaining visible fundamental frequency light reaches the deep ultraviolet frequency double crystal through the plano-concave output mirror, and the deep ultraviolet double The frequency crystal 7 is placed in a vacuum device, and the 213nm deep ultraviolet laser is output from the flat-concave output mirror after being reflected by the flat mirror.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com