Near-infrared luminescence bismuth-doped multi-component fiber and preparation method

A near-infrared, multi-component technology, applied in clad optical fiber, optical waveguide and light guide, etc., to achieve the effect of avoiding bismuth volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The preparation process of the near-infrared luminescent bismuth-doped multi-component optical fiber of this embodiment is as follows:

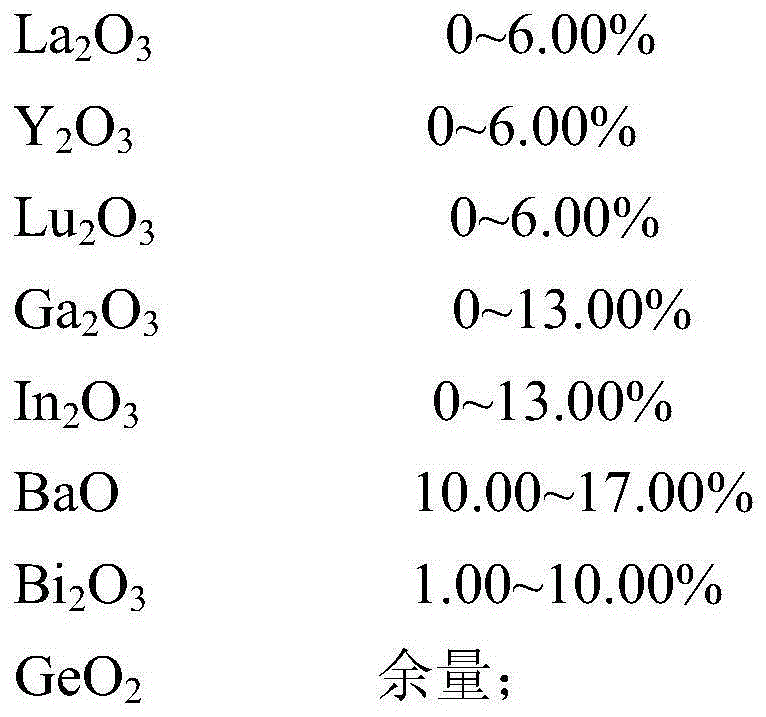

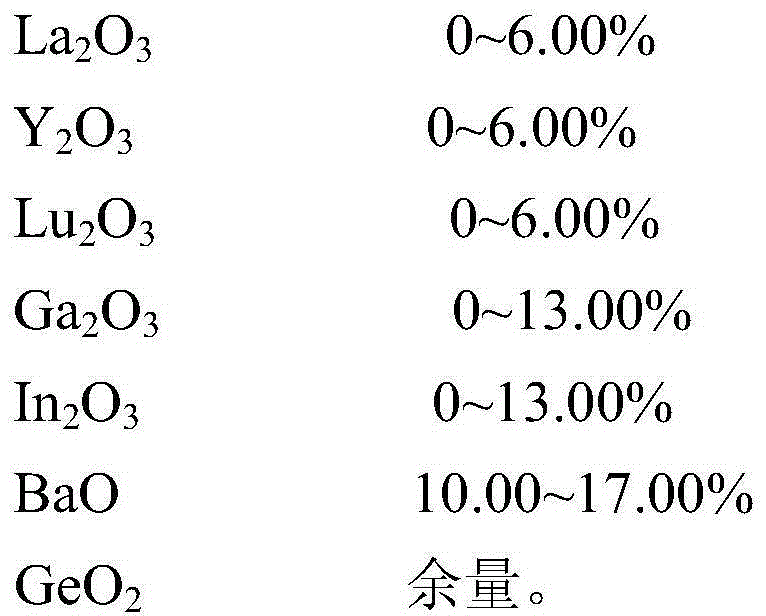

[0033] (1) Using lanthanum oxide, yttrium oxide, lutetium oxide, gallium oxide, indium oxide, barium carbonate, bismuth oxide, and germanium oxide as raw materials, using the traditional melting-quenching method, the optical fiber core glass described in Table 1 The bulk glass samples were prepared separately from the molar composition of the cladding glass and the melting process conditions; the glass samples were annealed according to the annealing process described in Table 1 to eliminate the residual stress in the glass and prevent the glass from breaking during processing.

[0034] (2) Processing the cladding and core glass prepared in the step (1) into a rod shape and polishing respectively.

[0035] (3) Drill a hole in the center of the clad glass rod along the axial direction, and polish the inner wall of the hole.

[0036] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com