Program heating analysis equipment and method for testing property of its catalyst

A technology for temperature-programmed and analytical equipment, which is used in chemical analysis, temperature control, and non-electrical variable control using catalysis. Waiting time, improving test efficiency, saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

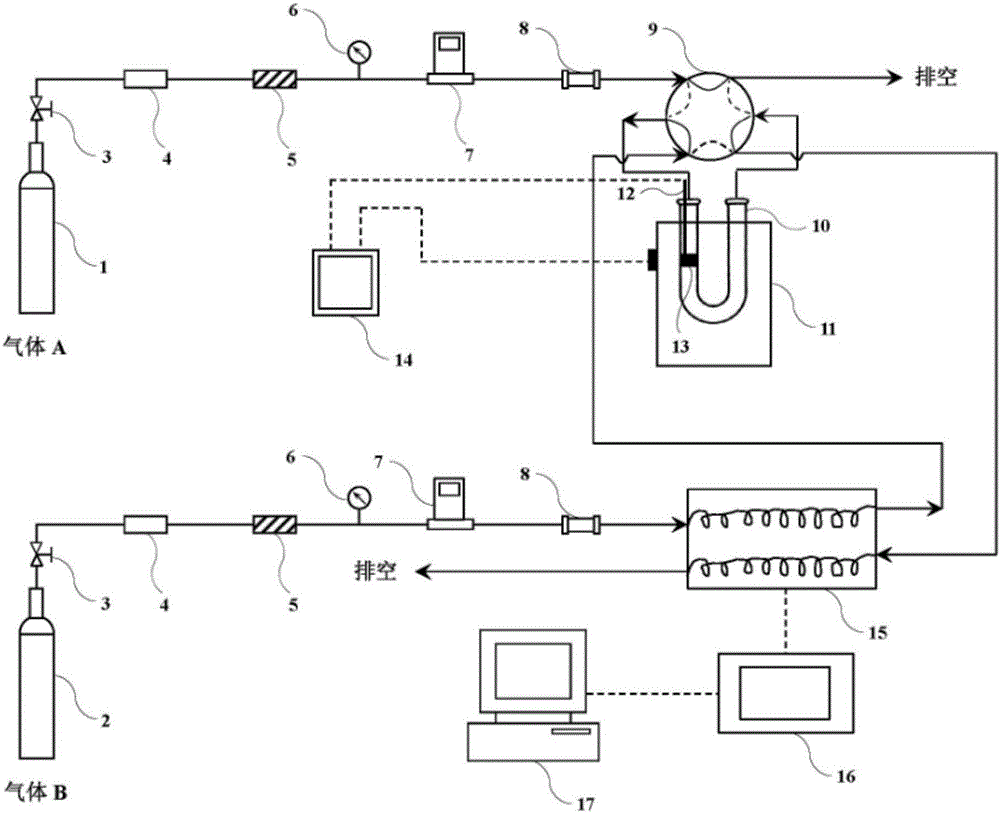

[0032] Such as figure 1 As shown, a temperature-programmed analysis equipment is used for temperature-programmed reduction, temperature-programmed oxidation and temperature-programmed desorption tests, including a first gas supply pipeline, a second gas supply pipeline, a six-way valve 9, a U-shaped reaction tube 10, Heating device, thermal conductivity cell detector 15, data processing workstation 16 and computer 17. In the diagram, the six-way valve 9 is the first interface, the second interface, the third interface, the fourth interface, and the fifth interface in the counterclockwise direction. and the sixth interface; the first gas supply line is connected to the first interface of the six-way valve 9, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com