Turntable type drilling machine system based on tool surface dynamic control of underground drilling tool and drilling method based on tool surface dynamic control of underground drilling tool

A dynamic control and tool face technology, which is applied in the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of difficult to determine the angle of rotating top drive or turntable, tool deviation of power drilling tools, and wellbore deviation from the design trajectory To achieve the possible effects of improving control accuracy and operating efficiency, correcting drift, and reducing the coupling between control and drilling tool offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

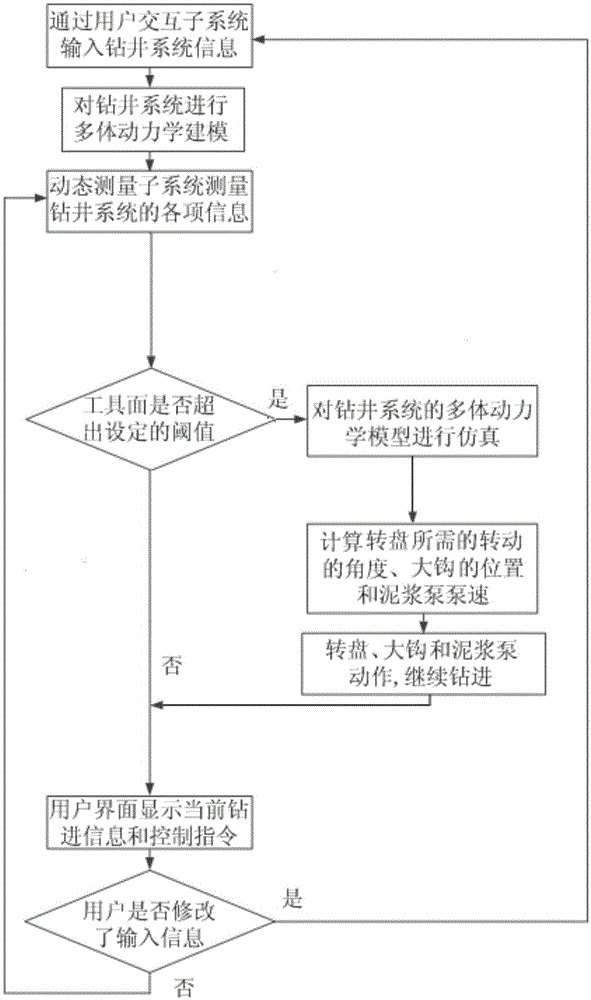

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

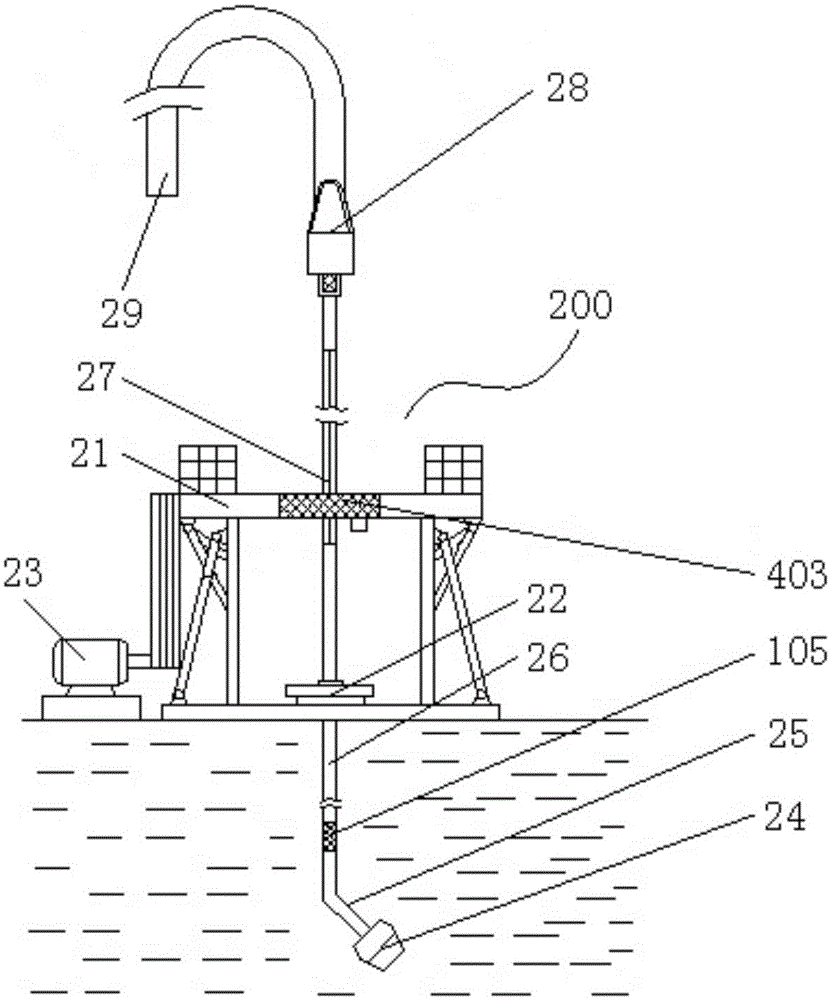

[0020] like figure 1 , figure 2 As shown, the drilling rig system of the present invention includes a dynamic control system 100 and a drilling system 200 .

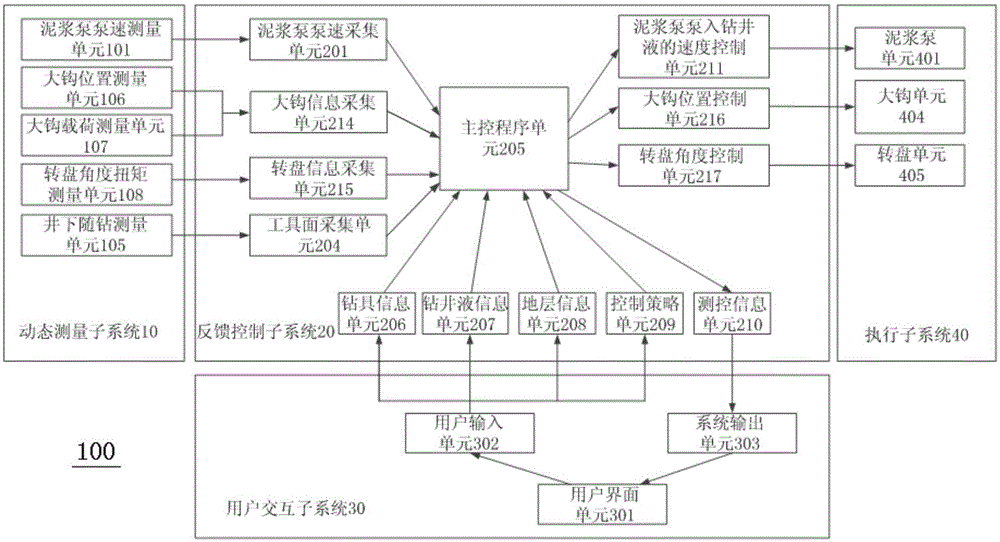

[0021] like figure 1 As shown, the dynamic control system 100 includes a dynamic measurement subsystem 10 , a feedback control subsystem 20 , a user interaction subsystem 30 and an execution subsystem 40 .

[0022] Among them, the dynamic measurement unit subsystem 10 includes a mud pump speed measurement unit 101 , a hook position measurement unit 102 , a turntable lifting force measurement unit 103 , a turntable angle torque measurement unit 104 and a downhole measurement unit 105 .

[0023] Feedback control subsystem 20 includes mud pump speed acquisition unit 201, hook information acquisition unit 202, turntable information acquisition unit 203, tool face acquisition unit 204, main contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com