A dynamic control system and method for the tool face of a downhole directional dynamic drilling tool

A dynamic control and tool face technology, which is applied to the automatic control system of drilling, directional drilling, drilling equipment, etc., can solve problems such as difficulty in determining the angle of the rotating top drive or turntable, the deviation of the wellbore from the designed trajectory, and the reduction of drilling efficiency. Achieve the effects of improving control accuracy and operating efficiency, improving wellbore quality, and reducing the probability of sticking and stuck pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

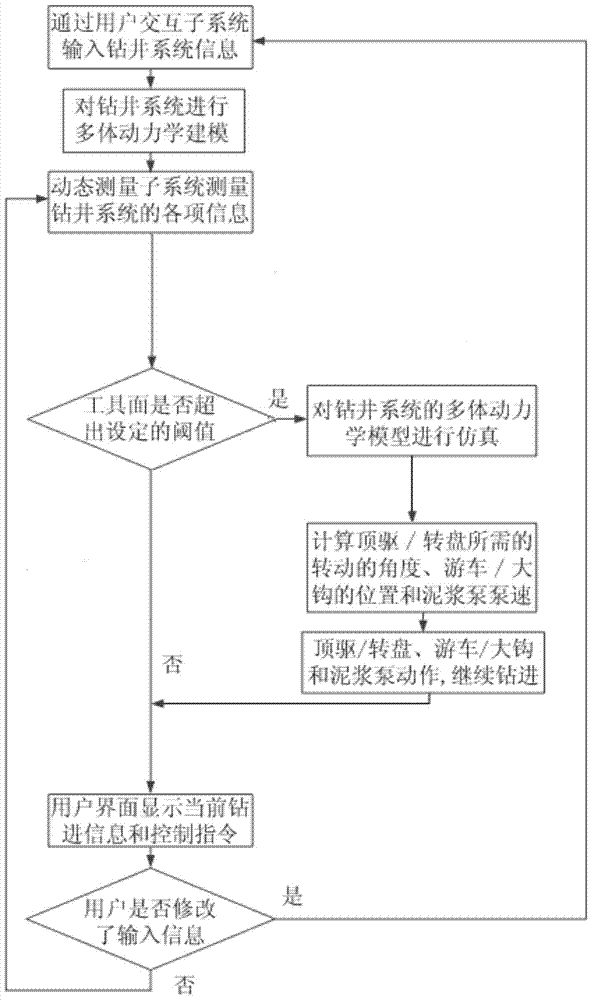

Method used

Image

Examples

Embodiment 1

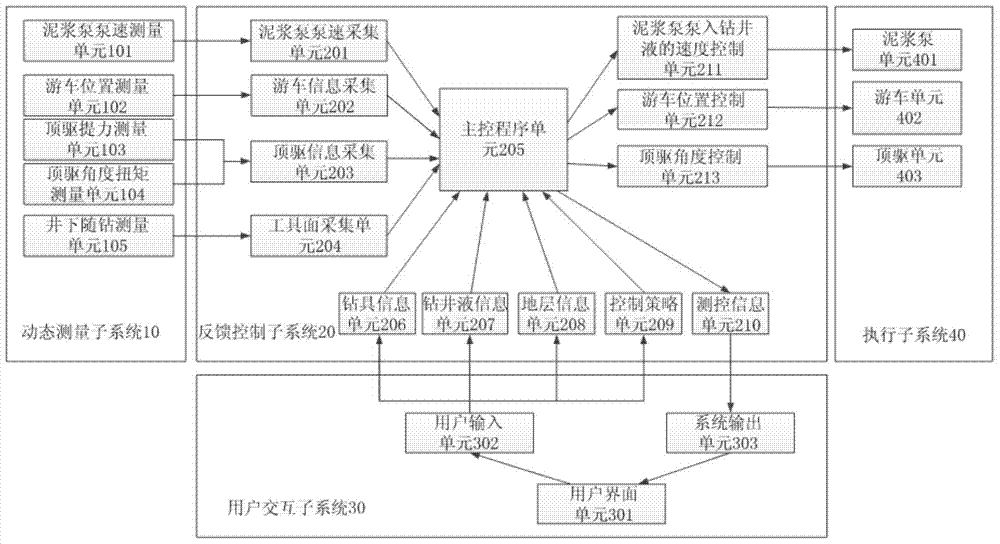

[0022] like figure 2 As shown, when the top drive is used for drilling, the dynamic measurement unit subsystem 10 includes a mud pump speed measurement unit 101, a traveling block position measurement unit 102, a top drive lifting force measurement unit 103, a top drive angle torque measurement unit 104 and Downhole measurement while drilling unit 105 .

[0023] Feedback control subsystem 20 includes mud pump pump speed acquisition unit 201, traveling block information acquisition unit 202, top drive information acquisition unit 203, tool face acquisition unit 204, main control program unit 205, drilling tool information unit 206, drilling fluid information unit 207 , formation information unit 208 , control strategy unit 209 , measurement and control information unit 210 , speed control unit 211 for mud pump pumping drilling fluid, traveling block position control unit 212 and top drive angle control unit 213 . Wherein, the output ends of the mud pump speed measuring unit 1...

Embodiment 2

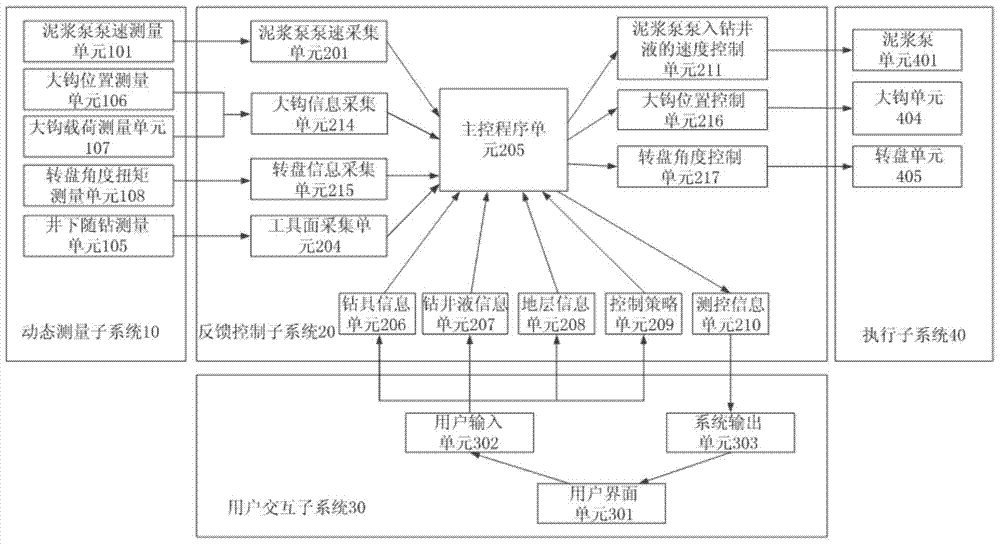

[0028] like image 3 As shown, when the rotary table is used for drilling, the principle and structure of the dynamic control system for the tool face of the downhole directional dynamic drilling tool implemented in this implementation are similar to those of the top drive for drilling, the difference is that:

[0029] In the dynamic measurement unit subsystem 10, the hook position measurement unit 106 is used to replace the traveling block position measurement unit 102, the hook load measurement unit 107 is used to replace the top drive lifting force measurement unit 103, and the turntable angle torque measurement unit 108 is used to replace the top drive angle The torque measuring unit 104 and other units are the same as those in the first embodiment.

[0030] In the feedback control subsystem 20, the hook information collection unit 214 that is electrically connected to the hook position measurement unit 106 and the hook load measurement unit 107 is used to replace the trav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com