Sensorless control method and device for motor

A control method and control device technology, applied in the direction of current controller, etc., can solve the problems of not considering the high-frequency change of the differential term of the inductance, the inability to express the real characteristics of the inductance, and the high-frequency change can not be ignored, so as to avoid control divergence and ensure The effect of closed-loop control convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

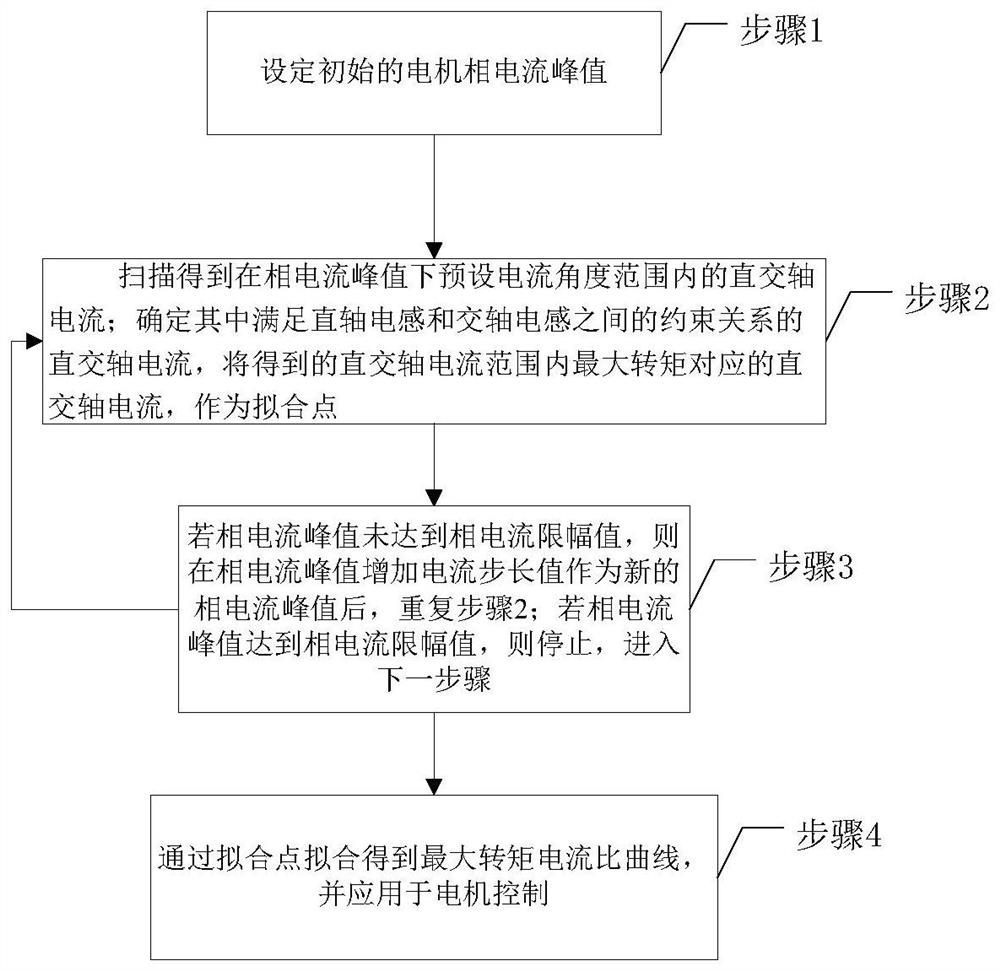

[0040] refer to figure 1 , which is a schematic flowchart of a motor position sensorless control method provided by the present invention, including specific steps.

[0041] Step 1, set the initial motor phase current peak value.

[0042] In a specific implementation, usually the initial peak value of the phase current is smaller than the limit value of the phase current, in order to leave room for increasing the current step value, the peak value of the phase current may refer to the three-phase current vector amplitude of the motor.

[0043] Step 2, scan to obtain the orthogonal axis current within the preset current angle range under the peak value of the phase current; determine the orthogonal axis current that satisfies the constraint relationship between the direct axis inductance and the quadrature axis inductance, and obtain the maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com