A kind of solid-state fermentation device and system and fermentation method

A solid-state fermentation and fermentation device technology, which is applied in the field of fermentation, can solve the problems of high labor intensity, large labor load, environmental pollution, mosquito and fly breeding in fermentation production, etc. It achieves simple equipment maintenance and standardized production, and is convenient for batch production and Batch operation, good effect of device combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

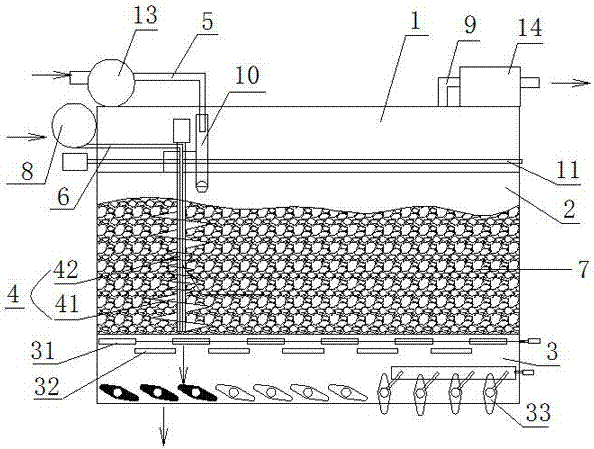

[0061] Embodiment 1 The construction of fermentation device

[0062] as attached figure 1 As shown, the present embodiment provides a solid-state fermentation device, including a working bin 1, a fermentation bin 2, and a quantitative discharge bin 3, and the working bin 1, the fermentation bin 2, and the quantitative output bin 3 are detachably connected to form a fermentation tank. equipment;

[0063] Described working chamber is connected with intake pipe 6, exhaust pipe 9 and feed pipe 5, and it is provided with work frame, and work frame is provided with some stirring devices 4 and some distribution devices 10; One end of described air intake pipe 6 and described Several stirring devices 4 are connected respectively; the feeding pipes 5 are respectively connected with the several distributing devices 10; the stirring ends of the stirring devices extend into the fermentation bin 2;

[0064] The top of the fermentation bin 2 communicates with the working bin 1, and the bo...

Embodiment 2

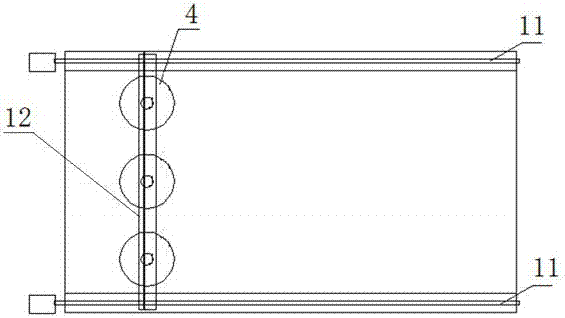

[0077] Others are the same as embodiment 1. The difference is that the working frame in the working warehouse is a mobile setting. as attached image 3As shown, two guide rails can be installed along the length direction (or X direction) of the working warehouse, and the working frame is erected between the two guide rails and reciprocates along the length direction of the working warehouse (or X direction) through the guide rails. sports. Similarly, the working warehouse can also be equipped with two guide rails along the width direction (or Y direction), and the work stand is erected between the two guide rails and reciprocates along the width direction (or Y direction) of the working warehouse through the guide rails. sports.

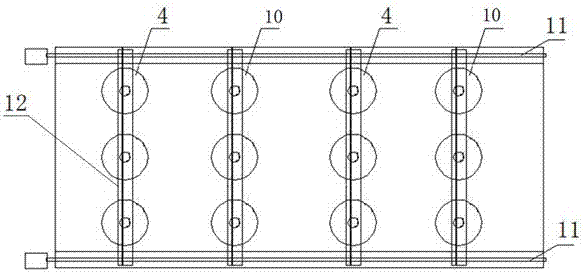

[0078] A number of stirring devices are fixedly arranged on the work frame along the direction perpendicular to the guide rail: the number of the stirring devices is several, and the several stirring devices are evenly arranged on the work frame, ...

Embodiment 3

[0080] Others are the same as embodiment 2. The difference is that the working frame is mobile, and the stirring device and the distributing device are also mobile. Figure 4 shown.

[0081] Two guide rails can be installed along the length direction (or X direction) of the working chamber, and the work frame is erected between the two guide rails and reciprocates along the length direction (or X direction) of the working chamber through the guide rails. Similarly, the working warehouse can also be equipped with two guide rails along the width direction (or Y direction), and the work stand is erected between the two guide rails and reciprocates along the width direction (or Y direction) of the working warehouse through the guide rails. sports.

[0082] A stirring device is installed on the working frame, and the stirring device can move back and forth on the working frame along the direction perpendicular to the guide rail, combined with the reciprocating movement of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com