Fabricated type bridge prefabricated part production base layout construction method and application

A prefabricated component and prefabricated technology, applied in manufacturing tools, auxiliary molding equipment, ceramic molding workshops, etc., can solve the problems of high safety hazards in the construction of prefabricated piers, affecting construction efficiency, wasting site area, etc., to improve civilized construction, The effect of reducing safety hazards and avoiding site waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

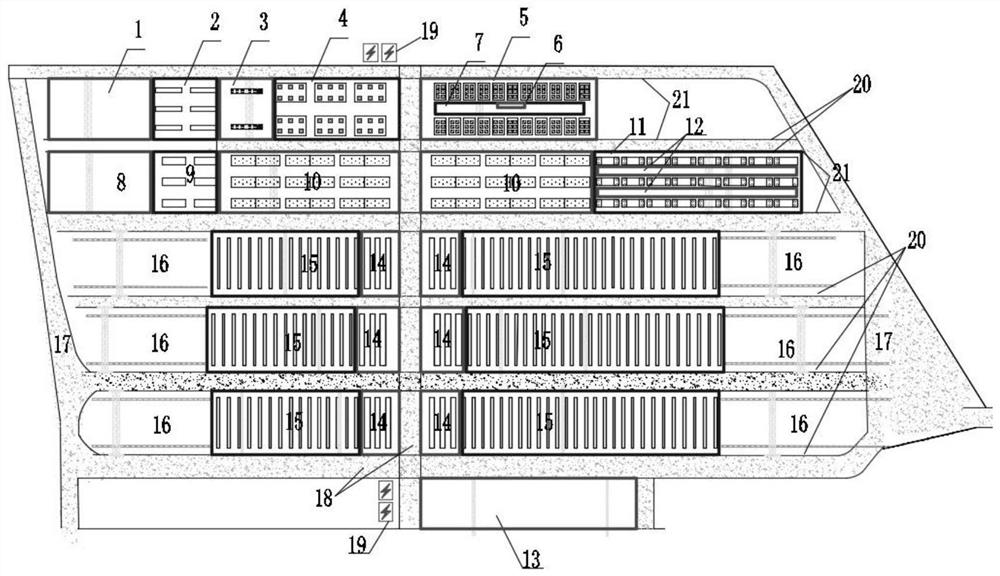

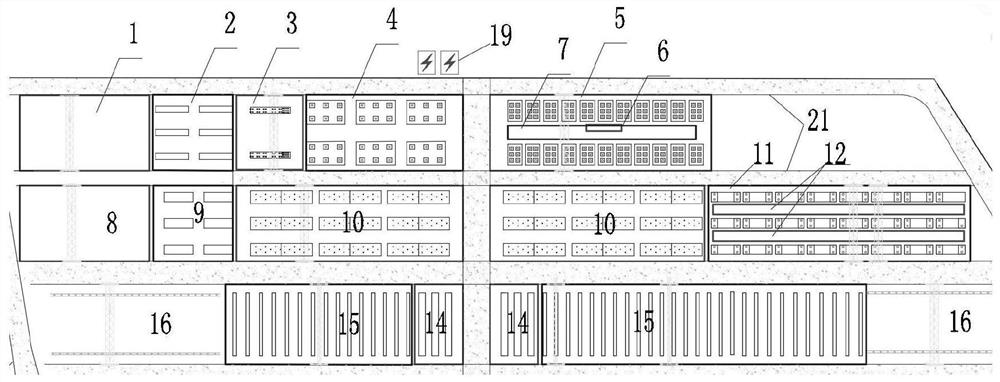

[0152] Acquisition of basic information on the construction site: the specific information is that the site covers an area of about 197 mu, and the construction planning area is a rectangular area of 480m*274m in length and width. After investigation and design, the geological condition survey is in a stable state. The demolition volume is small, and the transportation distance from the site is 5.6km. The transportation line is a fast trunk road, which allows large vehicles to pass. The power connection point is only 500m away from the site, and there is an independent mobile communication tower nearby.

[0153] The production process area of prefabricated prefabricated components is planned as follows:

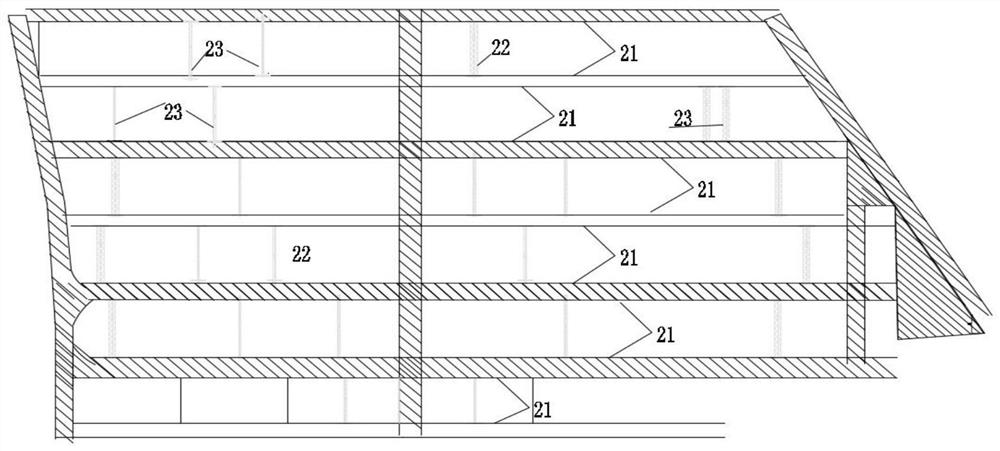

[0154] Prefabricated pier production line process area setting: steel raw material storage area, steel bar processing area, steel bar binding area, formwork assembly and turning area, concrete pouring area, prefabricated pier storage area, prefabricated pier turning chis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com