Organic montmorillonite modified polyurethane acrylic electrophoretic resin and electrophoretic paint

A technology of organic montmorillonite and polyurethane resin, which is applied in the field of coatings, can solve the problems of shrinkage, air bubbles, and impact on the coating surface, and achieve the effects of improving bonding strength, high industrial value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

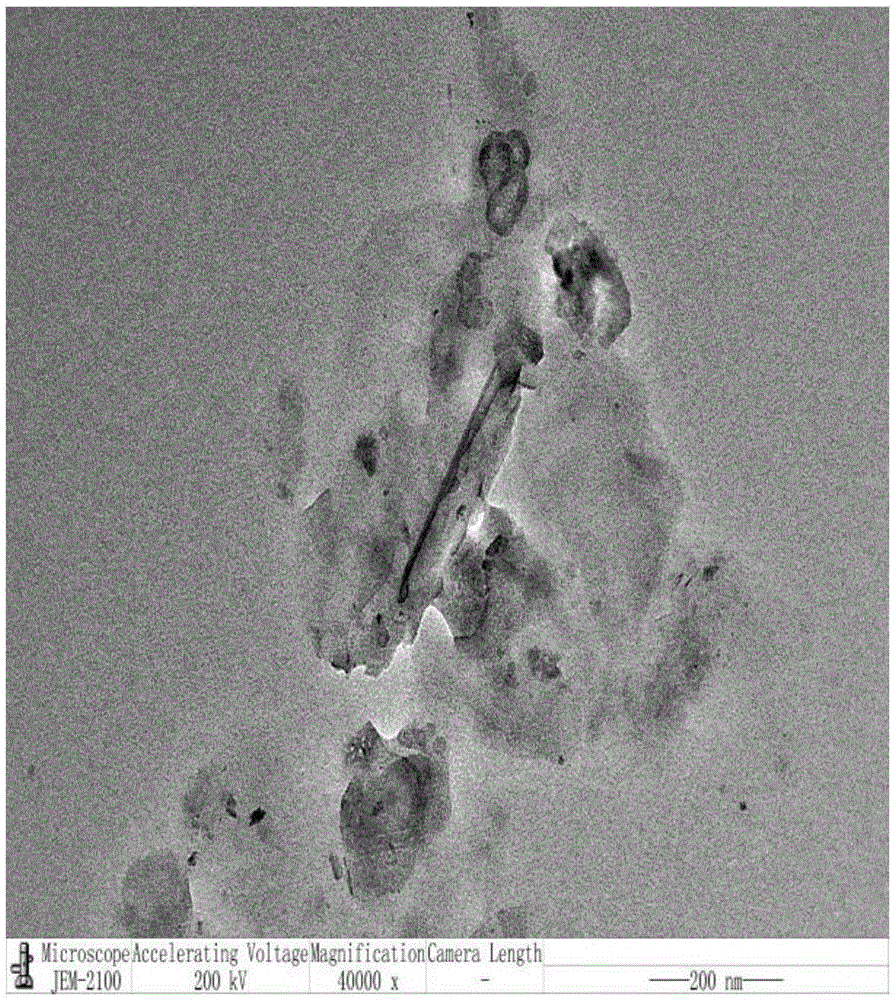

Image

Examples

Embodiment 1

[0038] Take 18.29g of N-methyldiethanolamine and 1.25g of trimethylolpropane, carry out dehydration treatment at 100°C for 1h, in the presence of solvent 1,4-dioxane, then add 21.55g of isocyanate dropwise at 30°C After reacting for 4 hours, 9.24 g of glacial acetic acid was added dropwise to carry out neutralization reaction for 1 hour, and finally a hydroxyl-terminated cationic polyurethane was obtained.

[0039] Then take 60g of the above-mentioned hydroxyl-terminated cationic polyurethane, disperse it with an appropriate amount of water, then take 12g of sodium-based montmorillonite and add a certain amount of deionized water to disperse, heat at 80°C for 1h, and add the above-mentioned montmorillonite dispersion liquid dropwise to the polyurethane emulsion At the same time, shake in ultrasonic for 4h. Then it was filtered and washed with suction, and then dried in vacuum for 6 hours at a temperature of 100°C. The product was then ground to 320 mesh.

[0040] Take 9.27g ...

Embodiment 2

[0044]Take 20g of N-methyldiethanolamine and 1.2g of trimethylolpropane, dehydrate at 100°C for 1h, in the presence of the solvent 1,4-dioxane, then add 21.55g of isocyanate dropwise and react at 30°C After 4 hours, 10.05 g of glacial acetic acid was added dropwise to carry out neutralization reaction for 1 hour, and finally a hydroxyl-terminated cationic polyurethane was obtained.

[0045] Then take 60g of the above-mentioned hydroxyl-terminated cationic polyurethane, disperse it with an appropriate amount of water, then take 12g of sodium-based montmorillonite and add a certain amount of deionized water to disperse, heat at 80°C for 1h, and add the above-mentioned montmorillonite dispersion liquid dropwise to the polyurethane emulsion At the same time, shake in ultrasonic for 4h. Then it was filtered and washed with suction, and then dried in vacuum for 6 hours at a temperature of 100°C. The product was then ground to 320 mesh.

Embodiment 3

[0050] Take 18.43g of N-methyldiethanolamine and 1.15g of trimethylolpropane, carry out dehydration treatment at 100°C for 1h, in the presence of solvent 1,4-dioxane, then drop 21.55g of isocyanate at 30°C After reacting for 4 hours, 9.27 g of glacial acetic acid was added dropwise to carry out neutralization reaction for 1 hour, and finally a hydroxyl-terminated cationic polyurethane was obtained.

[0051] Then take 60g of the above-mentioned hydroxyl-terminated cationic polyurethane, disperse it with an appropriate amount of water, then take 12g of sodium-based montmorillonite and add a certain amount of deionized water to disperse, heat at 80°C for 1h, and add the above-mentioned montmorillonite dispersion liquid dropwise to the polyurethane emulsion At the same time, shake in ultrasonic for 4h. Then it was filtered and washed with suction, and then dried in vacuum for 6 hours at a temperature of 100°C. The product was then ground to 320 mesh.

[0052] Take 9.27g of polyo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com