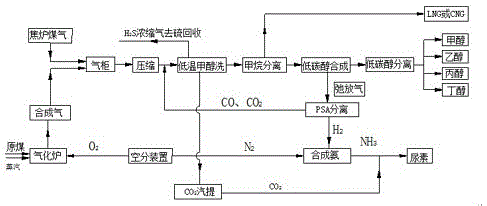

Method for production of low carbon alcohol and combined production of natural gas and urea from synthetic gas and coke oven gas

A technology of coke oven gas and low-carbon alcohol, which is applied in chemical instruments and methods, preparation of organic compounds, gas fuel, etc., can solve problems such as hydrogen replenishment, adjust excess production capacity, facilitate product diversification, and promote energy saving and reduction row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Feed raw coal, water vapor and oxygen from the air separation unit into the gasifier to obtain crude synthesis gas, then pass the crude synthesis gas and coke oven gas into the gas cabinet to fully mix to form a hydrogen-carbon molar ratio that satisfies the low-carbon alcohol synthesis. 2 Raw material gas with / CO=3.6.

[0040] The raw material gas is compressed to 3.5MPa and enters the low-temperature methanol washing and purification device to remove impurities such as hydrogen sulfide and carbon dioxide. 2 S off to less than 0.1ppm, CO 2 Less than 20ppm, the hydrogen sulfide H removed 2 S desulfurization recovery, the removed carbon dioxide through CO 2 Purification by steam stripping.

[0041] The raw material gas washed and purified by low-temperature methanol enters the methane separation, and the methane in the crude gas is separated to obtain LNG at a temperature of -162°C and a pressure of 3.5Mpa by using the cryogenic separation technology of American Chem...

Embodiment 2

[0046] Feed raw coal, water vapor and oxygen from the air separation unit into the gasifier to obtain crude synthesis gas, then pass the crude synthesis gas and coke oven gas into the gas cabinet to fully mix to form a hydrogen-carbon molar ratio that satisfies the low-carbon alcohol synthesis. 2 Raw material gas with / CO=2.9.

[0047] The raw material gas is compressed to 5.0MPa and enters the low-temperature methanol washing and purification device to remove impurities such as hydrogen sulfide and carbon dioxide. 2 S off to less than 0.1ppm, CO 2 Less than 20ppm, the hydrogen sulfide H removed 2 S desulfurization recovery, the removed carbon dioxide through CO 2 Purification by steam stripping.

[0048] The raw material gas washed and purified by low-temperature methanol enters the methane separation, and the methane in the crude gas is separated to obtain LNG at a temperature of -165°C and a pressure of 5.0Mpa by using the cryogenic separation technology of American Chem...

Embodiment 3

[0053] Feed raw coal, water vapor and oxygen from the air separation unit into the gasifier to obtain crude synthesis gas, then pass the crude synthesis gas and coke oven gas into the gas cabinet to fully mix to form a hydrogen-carbon molar ratio that satisfies the low-carbon alcohol synthesis. 2 Raw material gas with / CO=4.1.

[0054] The raw material gas is compressed to 4.5MPa and enters the low-temperature methanol washing and purification device to remove impurities such as hydrogen sulfide and carbon dioxide. 2 S off to less than 0.1ppm, CO 2 Less than 20ppm, the hydrogen sulfide H removed 2 S desulfurization recovery, the removed carbon dioxide through CO 2 Purification by steam stripping.

[0055] The raw material gas washed and purified by low-temperature methanol enters methane separation, and the methane in the gas is separated by supercritical gas extraction and separation technology at a pressure of 4.5MPa and a temperature of -77°C to obtain CNG (compressed na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com