Gas production drug for automobile safety belt pretensioner and preparation method of gas production drug

A technology of seat belt pretensioner and gas-generating agent, which is applied in the production of compressed gas, explosives, attack equipment, etc., can solve problems such as output performance degradation, and achieve the effects of improving stability, fewer processes, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides the preparation method of the above-mentioned gas-generating medicine for the automobile seat belt pretensioner, comprising the following steps:

[0034] Weigh each component according to the above proportions, add combustible agent, binder, oxidant, combustion enhancer and solvent into the kneader to knead into a drug mass, and then use plunger extrusion to extrude the drug mass into a drug bar, and then the drug bar Dry and cut into medicine granules, sieve the medicine granules to remove damaged medicine granules and powder, obtain complete and uniform medicine granules, and finally dry to obtain gas producing medicine.

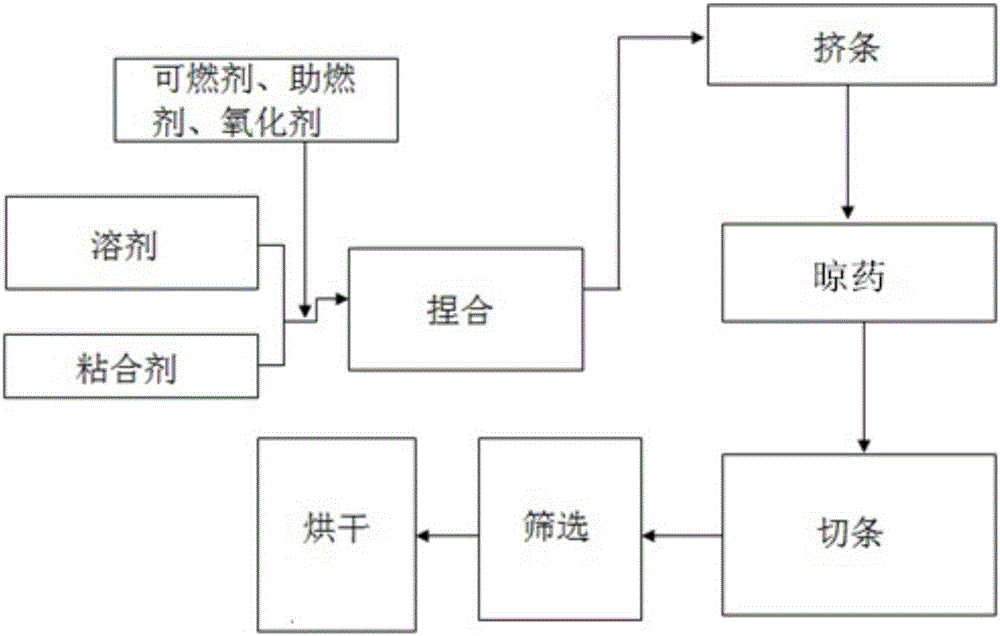

[0035] When kneading in a kneader, you can first add a binder and a solvent to knead for a period of time, then add a combustion aid, a combustible agent and an oxidant in sequence, and continue to knead into a drug group, such as figure 1 shown; it is also possible to knead the solvent and the oxidizing agent for...

Embodiment 1

[0045] The gas-generating drug in this example includes 55% of strontium nitrate, 36% of 5-aminotetrazole with an average particle size below 10 μm, 3% of ultrafine silicon powder with a particle size of less than 2 μm, and 6% of hydroxypropyl methylcellulose.

[0046] The preparation process of the gas-generating medicine is as follows: figure 1 Shown as:

[0047] Weigh 55% of strontium nitrate, 36% of 5-aminotetrazole with an average particle size below 10 μm, 3% of ultrafine silicon powder with a particle size of less than 2 μm, and 6% of hydroxypropyl methylcellulose. Strontium nitrate needs to be added with a certain amount of silicon dioxide for ball milling and sieving before use, so as to pretreat the irregular crystal shape and ensure the consistency of the material.

[0048] Step 1: Knead

[0049] Divide strontium nitrate and 5-aminotetrazole into two equal parts, first pour hydroxypropyl methylcellulose and solvent (volume ratio of alcohol to deionized water is 1:...

Embodiment 2

[0061] The gas-generating drug of this example includes 43% of strontium nitrate, 25% of potassium nitrate, 28% of 5-aminotetrazole with an average particle size below 10 μm, 0.5% of boron powder with a particle size of less than 2 μm, and 3.5% of methylcellulose.

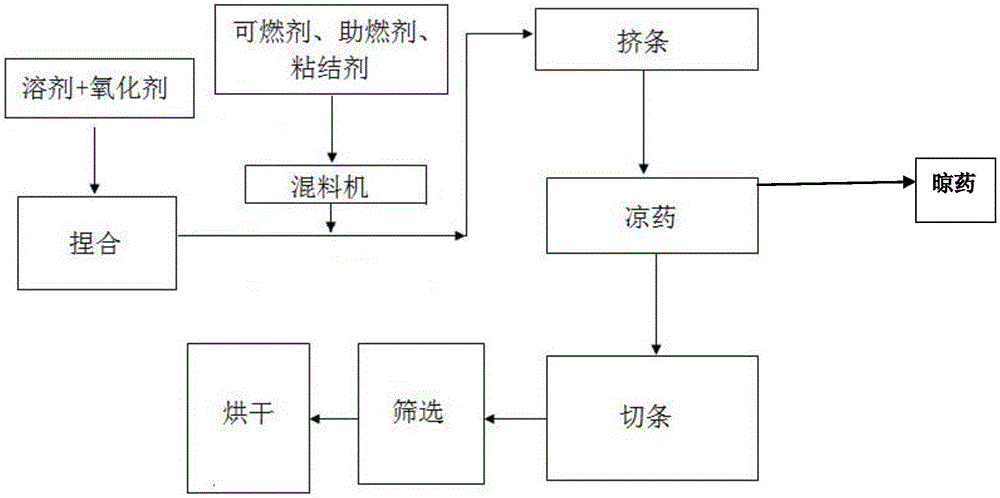

[0062] The preparation process of the gas-generating medicine is as follows: figure 2 Shown as:

[0063] Weigh 43% of strontium nitrate, 25% of potassium nitrate, 31% of 5-aminotetrazole with an average particle size of less than 10 μm, 0.5% of boron powder with a particle size of less than 2 μm, and 3.5% of methylcellulose. Before use, strontium nitrate and potassium nitrate need to add a certain amount of silicon dioxide for ball milling and sieving treatment to pretreat the irregular crystal shape and ensure the consistency of the material.

[0064] Step 1: Knead

[0065] Add the weighed methyl cellulose, silicon powder, and 5-aminotetrazole into a V-type mixer and dry mix for more than 30 minutes. First add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com