Electrostatic self-assembly carbon nano tube/nano-carbon black composite mortar as well as preparation method and application thereof

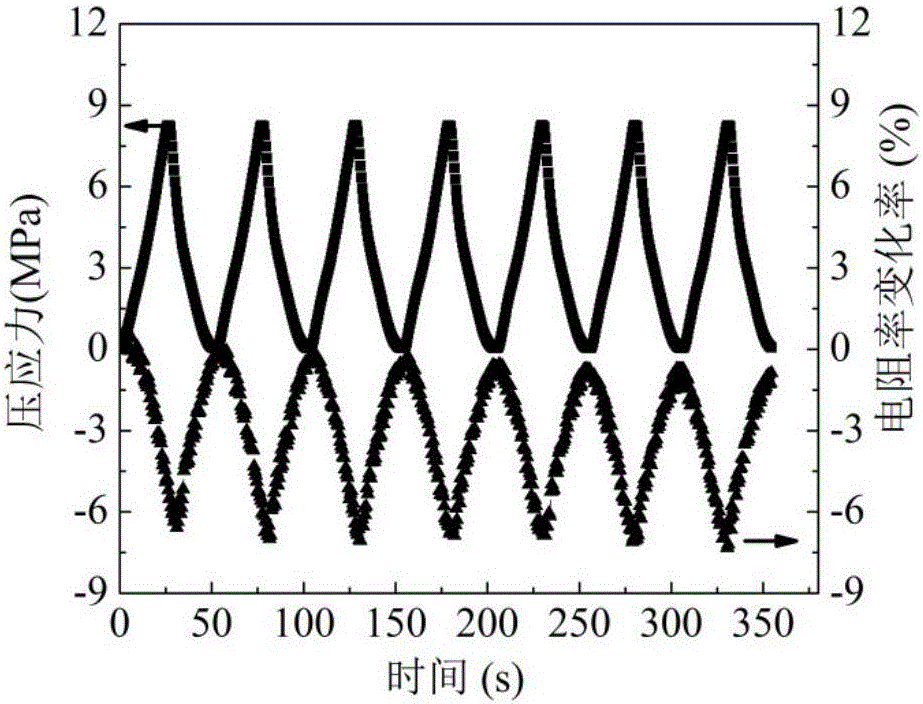

An electrostatic self-assembly and carbon nanotube technology, which is applied in the field of building materials, can solve the problems of reducing the material properties with a large amount of nanocarbon black, and the carbon nanotubes and nanocarbon black are not easy to disperse, etc., to achieve superior pressure sensitivity, pressure sensitive The effect of stability and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

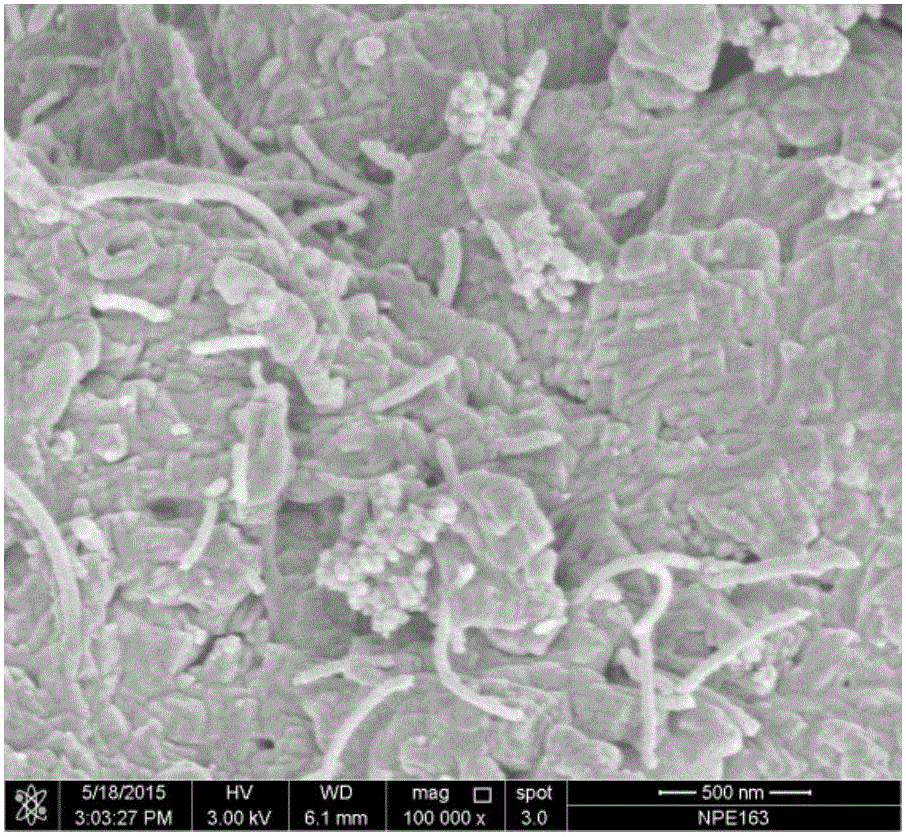

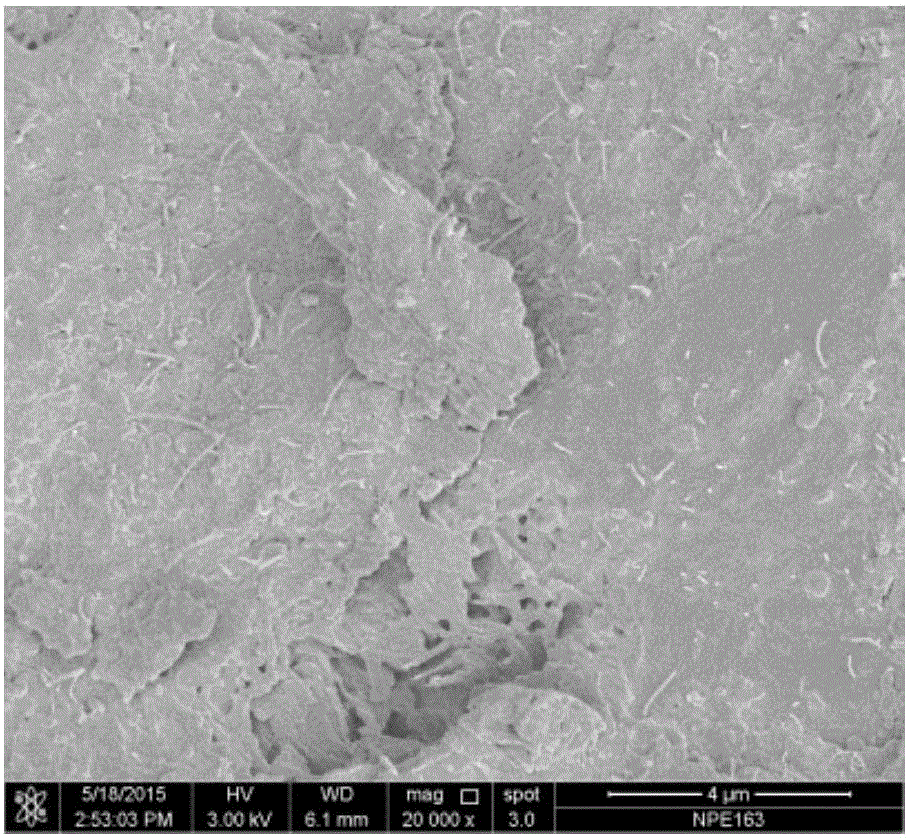

[0042] The electrostatic self-assembled carbon nanotube / nanocarbon black composite mortar is prepared according to the following steps:

[0043] (1) Take 90 parts of raw material cement; 10 parts of silica fume; 4 parts of electrostatic self-assembled carbon nanotubes / nanocarbon black; 2.5 parts of water reducing agent; 150 parts of standard sand; 42 parts of water;

[0044] (2) Add electrostatically self-assembled carbon nanotubes / nanocarbon black, silica fume, water, water reducing agent, cement and standard sand in sequence in the cement mortar mixer, and stir evenly to obtain the mixture;

[0045] (3) Pouring the obtained mixture into a mould, then placing the mold on a vibrating table, vibrating to the surface of the mixture in the mould;

[0046] (4) According to the size of the mixture in the mould, insert the electrode used to connect the external circuit, and then vibrate slightly to ensure that the electrode and the mixture are in good contact;

[0047] (5) Put the ...

Embodiment 2

[0062] The electrostatic self-assembled carbon nanotube / nanocarbon black composite mortar is prepared according to the following steps:

[0063] (1) Take 90 parts of raw material cement; 10 parts of silica fume; 7 parts of electrostatic self-assembled carbon nanotubes / nanocarbon black; 2.5 parts of water reducing agent; 150 parts of standard sand; 56 parts of water;

[0064] (2) Add electrostatically self-assembled carbon nanotubes / nanocarbon black, silica fume, water, water reducing agent, cement and standard sand in sequence in the cement mortar mixer, and stir evenly to obtain the mixture;

[0065] (3) Pour the obtained mixture into the mould, then place the mold on the vibrating table, and vibrate to the surface of the mixture in the mould;

[0066] (4) According to the size of the mixture in the mould, insert the electrode used to connect the external circuit, and then vibrate slightly to ensure that the electrode and the mixture are in good contact;

[0067] (5) Put the...

Embodiment 3

[0076] The electrostatic self-assembled carbon nanotube / nanocarbon black composite mortar is prepared according to the following steps:

[0077] (1) Take 90 parts of raw material cement; 10 parts of silica fume; 10 parts of electrostatic self-assembled carbon nanotubes / nano carbon black; 2.5 parts of water reducing agent; 150 parts of standard sand; 72 parts of water;

[0078] (2) Add electrostatically self-assembled carbon nanotubes / nanocarbon black, silica fume, water, water reducing agent, cement and standard sand in sequence in the cement mortar mixer, and stir evenly to obtain the mixture;

[0079] (3) Pour the obtained mixture into the mould, then place the mold on the vibrating table, and vibrate to the surface of the mixture in the mould;

[0080] (4) According to the size of the mixture in the mould, insert the electrode used to connect the external circuit, and then vibrate slightly to ensure that the electrode and the mixture are in good contact;

[0081] (5) Put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com