A method for advanced treatment of fluorine-containing wastewater

A technology for advanced treatment of waste water, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. To achieve the effect of enhanced coagulation effect, high fluorine removal efficiency and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

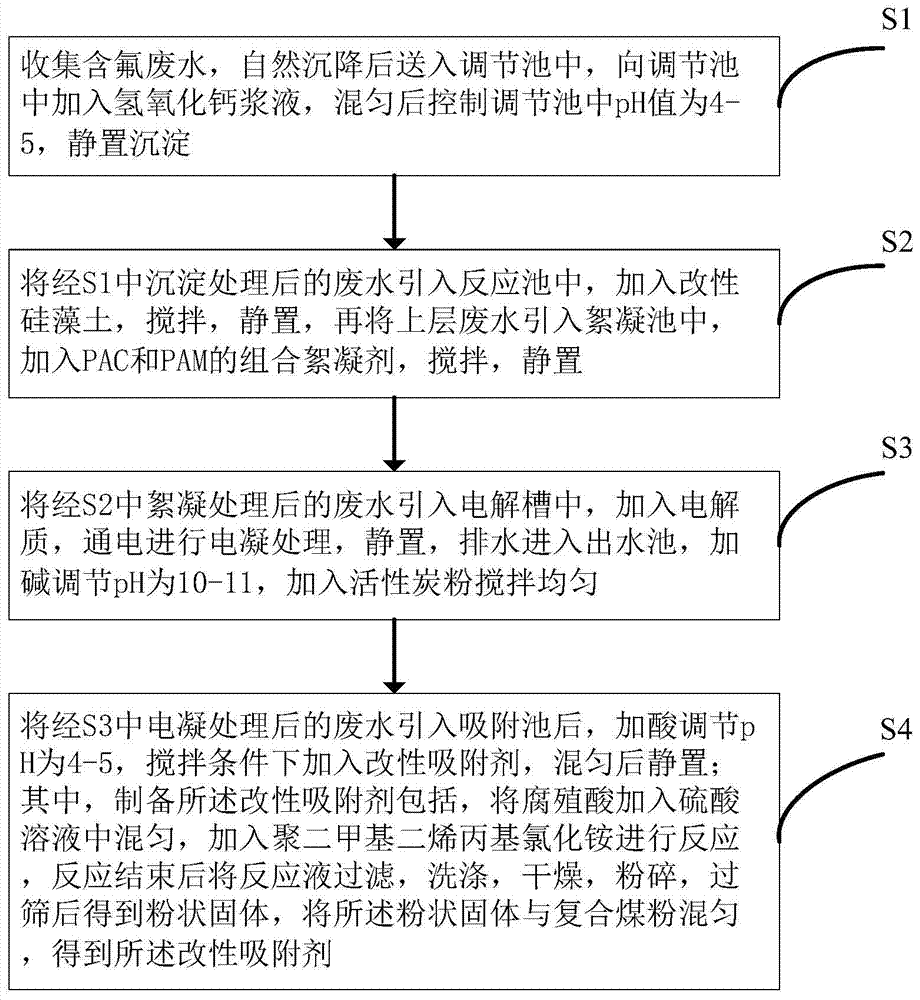

Image

Examples

Embodiment 1

[0036] A method for advanced treatment of fluorine-containing wastewater proposed in this embodiment comprises the following steps:

[0037] S1. Sedimentation: collect fluorine-containing wastewater, settle naturally for 5 hours, and send it to the regulating tank. Add calcium hydroxide slurry with a concentration of 15wt% to the regulating tank at a rate of 1.5m / min under stirring conditions, and control it in the regulating tank after mixing. The pH value is 4-6, and it is left to settle for 8 hours;

[0038] S2, flocculation: introduce the wastewater after the precipitation treatment in S1 into the reaction tank, add modified diatomite, wherein the preparation of the modified diatomite includes: adding water to the diatomite to obtain a pulp with a concentration of 20wt%, and Add 1.6wt% sodium hexametaphosphate and 0.4wt% sodium hydroxide based on diatomaceous earth, stir in a water bath at 50°C for 0.5h, let it stand for 0.6h, take the upper layer of mud and centrifuge, dr...

Embodiment 2

[0042] A method for advanced treatment of fluorine-containing wastewater proposed in this embodiment comprises the following steps:

[0043] S1. Sedimentation: collect fluorine-containing waste water, send it to the regulating tank after natural settlement for 8 hours, add calcium hydroxide slurry with a concentration of 20wt% to the regulating tank at a rate of 0.5m / min under stirring conditions, and control it in the regulating tank after mixing The pH value is 5-6, and it is left to settle for 6 hours;

[0044] S2, flocculation: introduce the wastewater after the precipitation treatment in S1 into the reaction tank, add modified diatomite, wherein the preparation of the modified diatomite includes: adding water to the diatomite to prepare a slurry with a concentration of 30wt%, and Add 1.2wt% sodium hexametaphosphate and 0.8wt% sodium hydroxide based on diatomaceous earth, stir in a water bath at 30°C for 1h, let stand for 0.3h, take the upper layer of mud and centrifuge, d...

Embodiment 3

[0048] A method for advanced treatment of fluorine-containing wastewater proposed in this embodiment comprises the following steps:

[0049] S1. Sedimentation: collect fluorine-containing waste water, send it to the regulating tank after natural sedimentation for 6 hours, add calcium hydroxide slurry with a concentration of 17wt% to the regulating tank at a rate of 1.0m / min under stirring conditions, and control it in the regulating tank after mixing The pH value is 4-6, and it is left to settle for 7 hours;

[0050] S2, flocculation: introduce the wastewater after the precipitation treatment in S1 into the reaction tank, add modified diatomite, wherein the preparation of the modified diatomite includes: adding water to the diatomite to prepare a pulp with a concentration of 25wt%, and Add 1.4wt% sodium hexametaphosphate and 0.6wt% sodium hydroxide based on diatomaceous earth, stir in a water bath at 40°C for 0.7h, let stand for 0.4h, take the upper layer of mud and centrifuge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com