Systems and method for hazardous waste incineration

A technology for hazardous waste and feeding system, applied in the field of hazardous waste incineration systems, can solve the problems of strong flue gas corrosiveness, inability to effectively dispose of hazardous waste, and difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The technical solutions and effects of the present invention will be further described below through specific embodiments. The following embodiments are only used to illustrate the content of the present invention, and the present invention is not limited to the following embodiments or examples. Simple changes made to the present invention by applying the concept of the present invention are all within the scope of protection of the present invention.

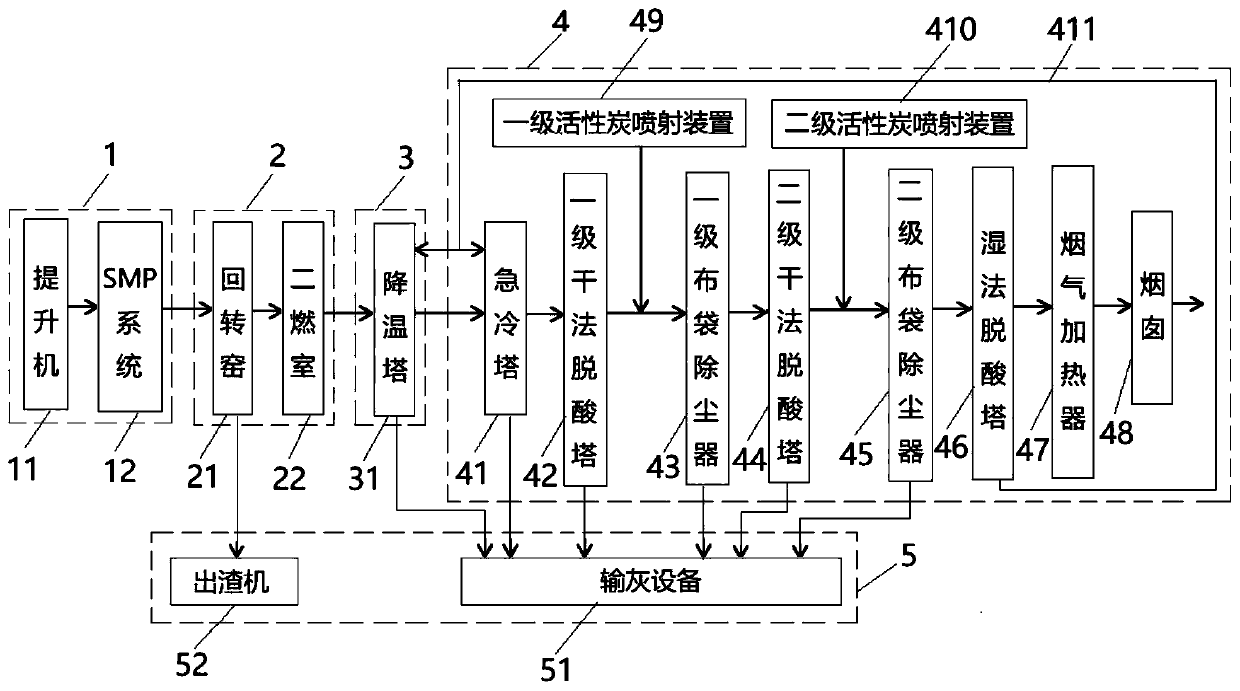

[0091] Such as figure 1 As shown, the system for hazardous waste incineration of the present invention includes a feeding system 1, an incineration system 2, a cooling system 3 and a flue gas treatment system 4 arranged in sequence;

[0092] The feeding system 1 includes a hoist 11 and an SMP system 12 arranged in sequence;

[0093] The hoist 11 is used to lift the hazardous waste to be treated to the SMP system 12;

[0094] The SMP system 12 includes a crusher, a mixer and a plunger pump arranged in sequence, for cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com