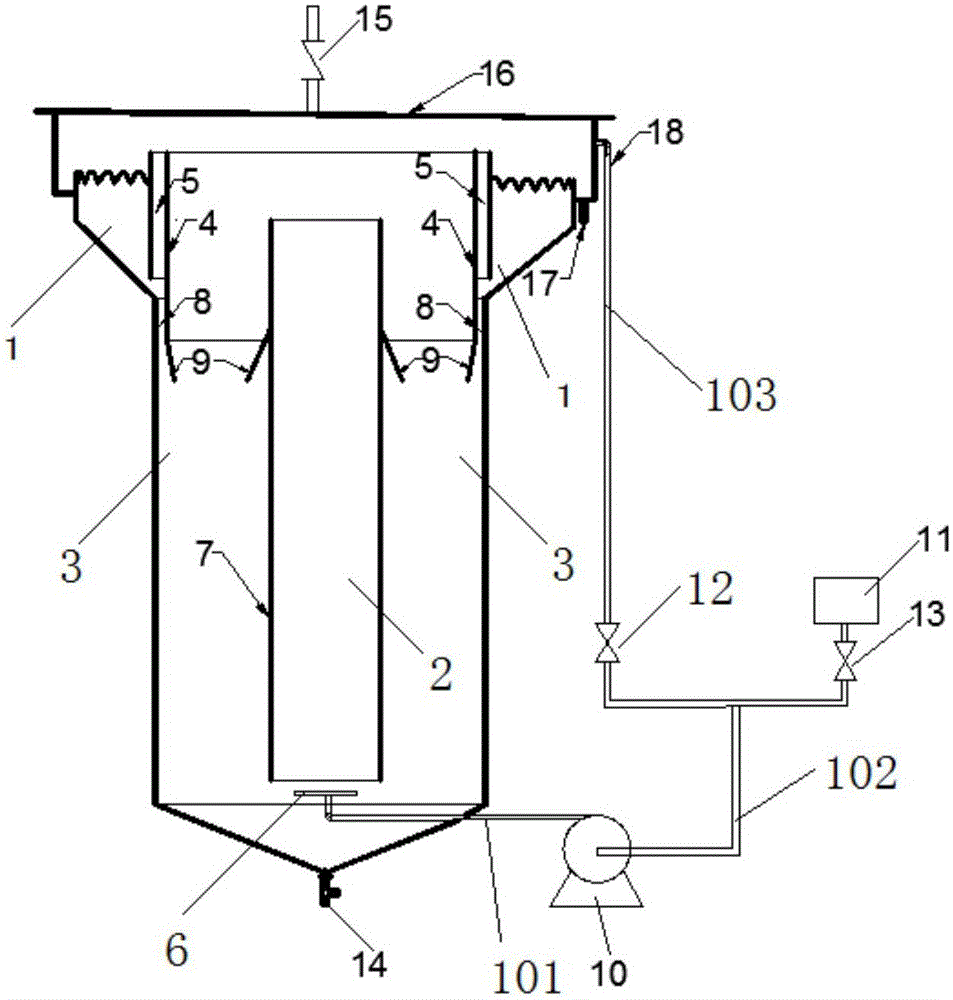

High-load metabolic regulation bioreactor and method for waste-water treatment

The invention relates to a bioreactor and a technology of metabolic regulation, which is applied to a high-load metabolic regulation bioreactor and the field of wastewater treatment by using the reactor, and can solve the problems of increased operating cost, high energy consumption and operating cost, and high energy consumption of effluent reflux. Achieve the effect of saving startup cost, low startup cost and fast startup speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063]Wastewater A COD21000mg / L, containing acrylic acid 15000mg / L, waste water B COD55000mg / L, containing sodium acrylate 52000mg / L, the water volume ratio of waste water A and waste water B is 3:1, according to the method of the present invention, the reflux ratio of the treated effluent is 1.125 . After mixing, the waste water does not add acid and alkali to adjust the pH, but adds nutrients such as nitrogen and phosphorus, and enters the high-load metabolic regulation bioreactor of the present invention for pretreatment. The HRT is 6h, and the inhibition rate of anaerobic methanogenesis of the waste water is reduced to 8%. , The BOD5 removal rate is 13%; then the effluent is supplemented with iron, cobalt, nickel trace elements and then treated with the EGSB reactor. The HRT is 24h, and the COD removal rate is above 90%; , the effluent does not contain acrylic acid or acrylate, and the COD drops below 120mg / L.

Embodiment 2

[0065] A certain waste water COD50000mg / L, containing acrylic acid 15000mg / L, sodium acrylate 13000mg / L, sodium acetate 20000mg / L, according to the method of the present invention, after adding nutrients such as nitrogen and phosphorus to adjust the pH of the waste water, it enters the high-load metabolism of the present invention. Regulate the bioreactor for pretreatment, HRT is 3.5h, the treatment load can reach 171kg / m3.d (calculated as acrylic acid), the inhibition rate of anaerobic methanogenesis of wastewater is reduced to 7%, and the removal rate of BOD5 is 10%; then the effluent is supplemented Iron, cobalt, and nickel trace elements are treated by EGSB reactor, the total HRT is 30h, and the COD removal rate is over 95%; the effluent of EGSB reactor is then treated by biological fluidized bed reactor, HRT=20h, and the effluent does not contain acrylic acid Or acrylate, COD dropped below 120mg / L.

Embodiment 3

[0067] A certain waste water COD42000mg / L, containing acrylic acid 15000mg / L, acetic acid 20000mg / L, according to the method of the present invention, after adding nutrients such as nitrogen and phosphorus to adjust the pH of the waste water, enter the high-load metabolic regulation bioreactor of the present invention for pretreatment , HRT is 3h, the treatment load can reach 120kg / m3.d (calculated as acrylic acid), the inhibition rate of anaerobic methanogenesis of wastewater is reduced to 8%, and the removal rate of BOD5 is 12%; then the effluent is supplemented with trace elements such as iron, cobalt and nickel EGSB reactor is used for treatment, HRT is 36h, COD removal rate is above 95%; EGSB reactor effluent is treated with biological fluidized bed reactor, HRT=20h, effluent does not contain acrylic acid or acrylate, COD is reduced to 120mg / Below L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com