Method for treating acid chromium-contained polluted waste water with molten iron residues as raw material

A treatment method, iron slag technology, applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, water pollutants, etc., can solve problems such as acidic chromium-containing pollution treatment methods, and achieve cost savings and density High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

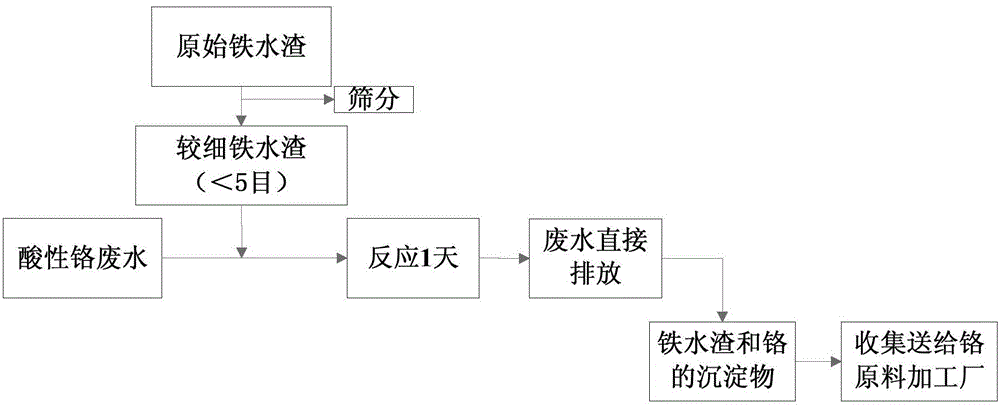

Method used

Image

Examples

Embodiment 1

[0038] Typical iron slag mainly contains 10%-15% silicon dioxide (SiO 2 ), 3%-8% magnesium oxide (MgO), 30%-50% calcium oxide (CaO), 20-35% elemental iron (MFe), 10-15% ferrous oxide (FeO), and A small amount of P 2 o 5 , Fe 2 o 3 and sulfide etc. The concrete composition of the molten iron slag in embodiment 1 is as follows: 13% silicon dioxide (SiO 2 ), 6% of magnesium oxide (MgO), 41% of calcium oxide (CaO), 28% of elemental iron (MFe), 13% of ferrous oxide (FeO), and the content of heavy metals in molten iron slag meets the total cadmium <0.1mg / kg, total mercury<0.05mg / kg, total arsenic<5mg / kg, total lead<5mg / kg, total copper<5mg / kg, total nickel<5mg / kg, total zinc<5mg / kg, total manganese<100mg / kg kg, total cobalt<1mg / kg, total selenium<1mg / kg, total vanadium<1mg / kg, total antimony<0.10mg / kg, total thallium<0.10mg / kg, total chromium<10mg / kg (hexavalent chromium< 0.1mg / kg).

[0039] Sieve the iron slag to a certain fineness and add it directly to the acidic chromiu...

Embodiment 2

[0049] The concrete composition of the molten iron slag in embodiment 2 is as follows: 11% silicon dioxide (SiO 2 ), 4% magnesium oxide (MgO), 32% calcium oxide (CaO), 21% elemental iron (MFe), 15% ferrous oxide (FeO), and the heavy metal content of molten iron slag meets the total cadmium <0.1mg / kg, total mercury<0.05mg / kg, total arsenic<5mg / kg, total lead<5mg / kg, total copper<5mg / kg, total nickel<5mg / kg, total zinc<5mg / kg, total manganese<100mg / kg kg, total cobalt<1mg / kg, total selenium<1mg / kg, total vanadium<1mg / kg, total antimony<0.10mg / kg, total thallium<0.10mg / kg, total chromium<10mg / kg (hexavalent chromium< 0.1mg / kg).

[0050] After sieving iron slag to 5 mesh, it is directly added to the acidic chromium-containing polluted wastewater (the content of trivalent chromium is 20mg / L, the content of hexavalent chromium is 20mg / L, and the pH is 4.9). The adding method is automatic dosing machine to join. After the iron slag and the acidic chromium-containing contaminated ...

Embodiment 3

[0052] The concrete composition of the molten iron slag in embodiment 3 is as follows: 14% silicon dioxide (SiO 2 ), 8% magnesium oxide (MgO), 48% calcium oxide (CaO), 33% elemental iron (MFe), 11% ferrous oxide (FeO), and the heavy metal content of molten iron slag meets the total cadmium <0.1mg / kg, total mercury<0.05mg / kg, total arsenic<5mg / kg, total lead<5mg / kg, total copper<5mg / kg, total nickel<5mg / kg, total zinc<5mg / kg, total manganese<100mg / kg kg, total cobalt<1mg / kg, total selenium<1mg / kg, total vanadium<1mg / kg, total antimony<0.10mg / kg, total thallium<0.10mg / kg, total chromium<10mg / kg (hexavalent chromium< 0.1mg / kg).

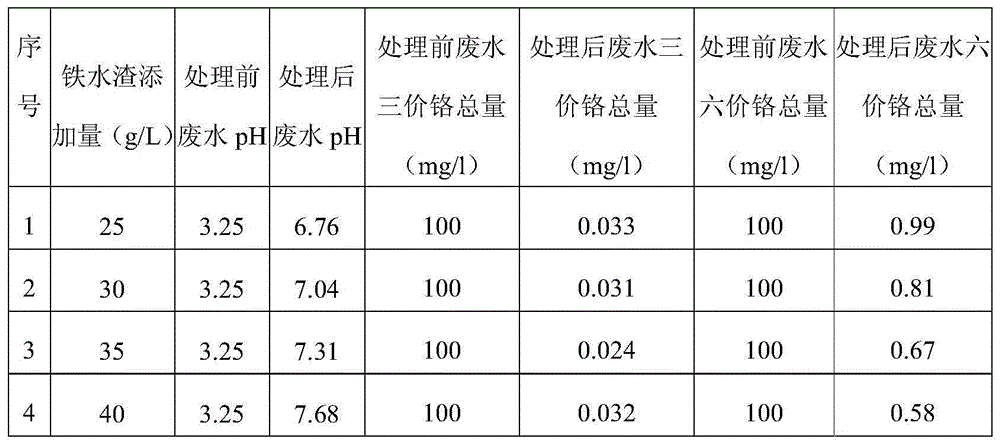

[0053] After the iron slag is sieved to 5 mesh, it is directly added to the acidic chromium-containing polluted wastewater (the content of trivalent chromium is 500mg / L, the content of hexavalent chromium is 500mg / L, and the pH is 2.2), and the adding method is manual sprinkling. Iron slag and acidic chromium-containing contaminated wastewater are ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com