Production device and method for recovering sulfur from sulfur slag

A technology of production equipment and production method, which is applied in the field of production equipment for sulfur recovery, and can solve the problems that thermal filtration cannot be industrialized, high cost, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

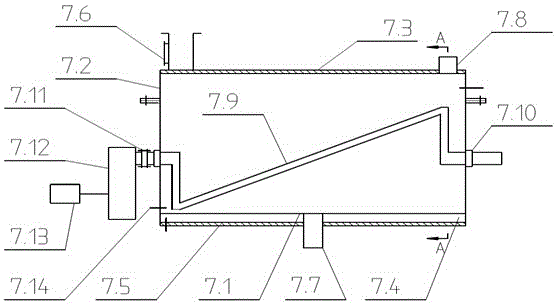

[0059] Examples of production equipment of the present invention figure 1 As shown, it includes a material preparation unit, a conveying unit, a pretreatment unit, a melting unit, a thermal filter unit and an air extraction unit; the material preparation unit includes a squirrel cage crusher 1, a vibrating screen 2 and a raw material bin 3; the conveying unit includes a circular Pan feeder 4 and electronic metering belt 5; the pretreatment unit includes a single-screw mixer 6 and a kneader 7; the melting unit includes a sulfur slag stirring and melting tank 8; the thermal filtration unit includes a submerged pump 9 , leaf filter 10 and liquid sulfur storage tank 11; the air extraction unit includes a water jet pump air extraction unit; the squirrel cage crusher 1, vibrating screen 2 and raw material bin 3 are arranged in sequence from top to bottom, and the raw material The bin 3 is connected to the disc feeder 4, and one end of the disc feeder 4 is connected to the electronic...

Embodiment 2

[0079] The difference between the equipment in this embodiment and the equipment in Example 1 is that the single-screw kneader is replaced by a twin-screw kneader. The difference between the twin-screw kneader and the single-screw kneader is that the cross-section It is kidney-shaped, and two screw rods 6.2 pass through the end plate 6.4 in parallel; the heating jacket 7.4 of the kneader 7 is connected with heat-conducting oil. The rest are the same as embodiment 1.

[0080] Production method for recovering sulfur from sulfur slag:

[0081] (1) Raw material preparation: 1303.7kg of direct leaching sulfur slag II (wet slag) is crushed by squirrel cage crusher 1, screened by vibrating screen 2, and stored in raw material bin 3;

[0082] (2) Pretreatment: The sulfur slag in the raw material bin 3 in step (1) is transported to the pretreatment unit through the disc feeder 4 and the electronic metering belt 5, and the pretreatment unit is composed of a twin-screw mixer 6 and a k...

Embodiment 3

[0087] The difference between the equipment in this embodiment and the equipment in Example 1 is that there is no kneader 7, and the discharge port 7.7 of the single-screw kneader 6 is connected to the feed port 8.7 of the sulfur slag stirring and melting tank 8. The rest are the same as embodiment 1.

[0088] Production method for recovering sulfur from sulfur slag:

[0089] (1) Raw material preparation: crush 550.5kg of direct leaching sulfur slag II (wet slag) through squirrel cage crusher 1, sieve with vibrating screen 2, and store in raw material bin 3;

[0090] (2) Pretreatment: The sulfur slag in the raw material bin 3 in step (1) is transported to the pretreatment unit through the disc feeder 4 and the electronic metering belt 5. The pretreatment unit is a single-screw mixer 6, and the sulfur The slag enters the feed port 6.5 of the single-screw kneader 6 for mixing, and enters the melting unit through the head 6.3 of the single-screw kneader 6 discharge port;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com