A method for processing stainless steel capillary cores on heat pipe plates

A stainless steel, capillary core technology, applied in metal processing equipment, manufacturing tools, electron beam welding equipment, etc., can solve the problems of reducing the capillary effect of high temperature heat pipes, loss of capillary effect of capillary core, fusing, etc., and achieves a small welding heat affected area, Tight bonding and high welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

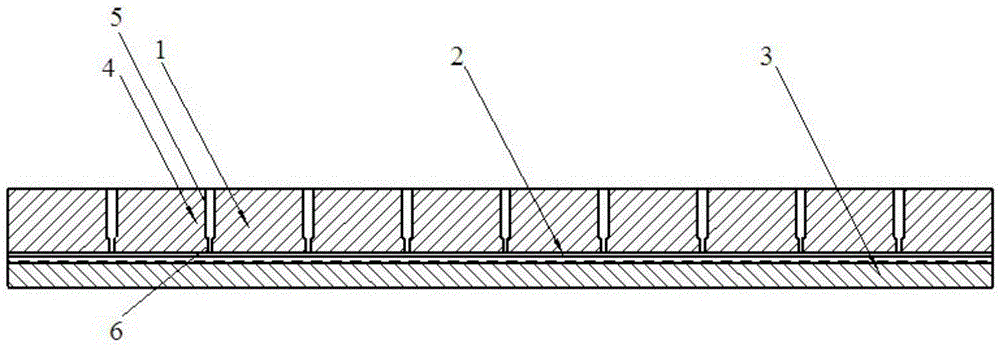

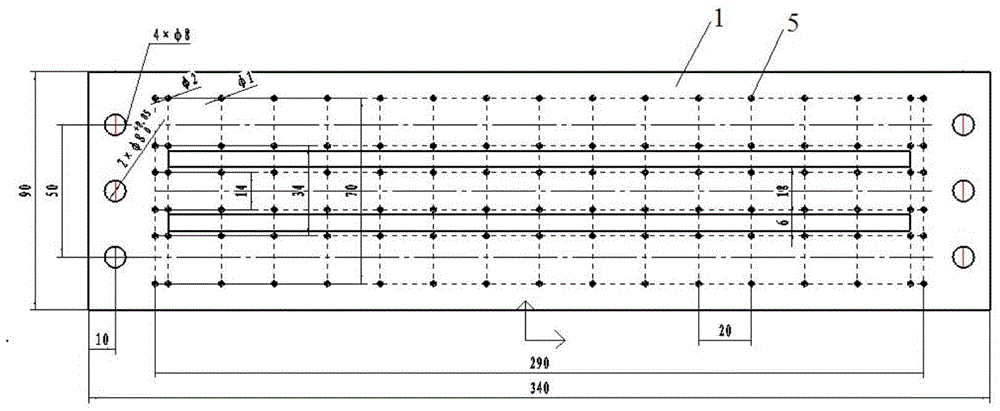

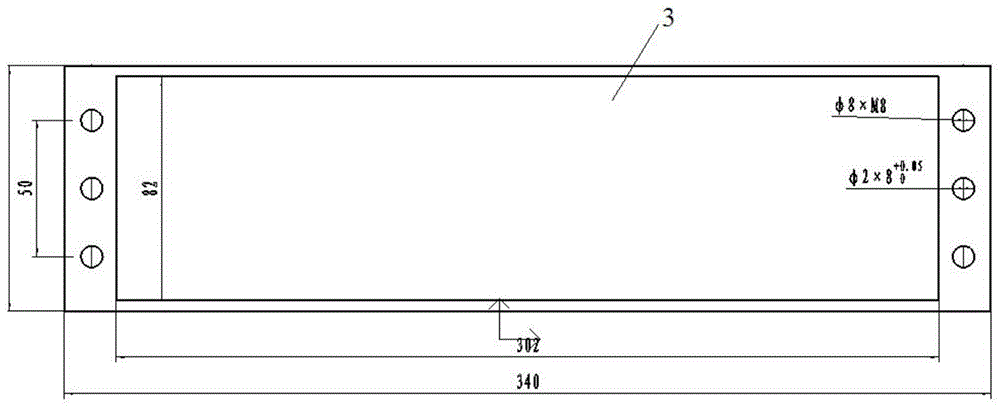

[0038] In order to illustrate the feasibility of this method, a 10mm thick copper plate T1 was used to process the copper template. The size of the copper template is 300×100mm. A number of through holes are processed on the copper template, each through hole is composed of a first round hole with a diameter of Φ2mm and a second round hole with a diameter of Φ1mm. Wherein, the depth of the second circular hole with a diameter of Φ1 mm is 3 mm. The through holes are arranged orthogonally, the distance between two adjacent through holes in the length direction of the template is 20 mm, and the distance between two adjacent through holes in the width direction of the template is 15 mm.

[0039] The plate is made of nickel-based superalloy, the grade is GH3044, and the thickness is 2.0mm. The specific processing process is as follows: (1) adopt the fastening structure in Fig. 2 to fix the 400-mesh stainless steel wire mesh on the GH3044 plate; (2) then place the workpiece to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com