Extra-thick sheet submerged-arc welding technique

A submerged arc welding and process technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of weld shrinkage resistance, high energy consumption, root weld bead cracking, etc., to reduce deformation and turn over times , The effect of reducing welding residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

[0026] A submerged arc welding process for an ultra-thick plate, comprising the following process parameters and steps:

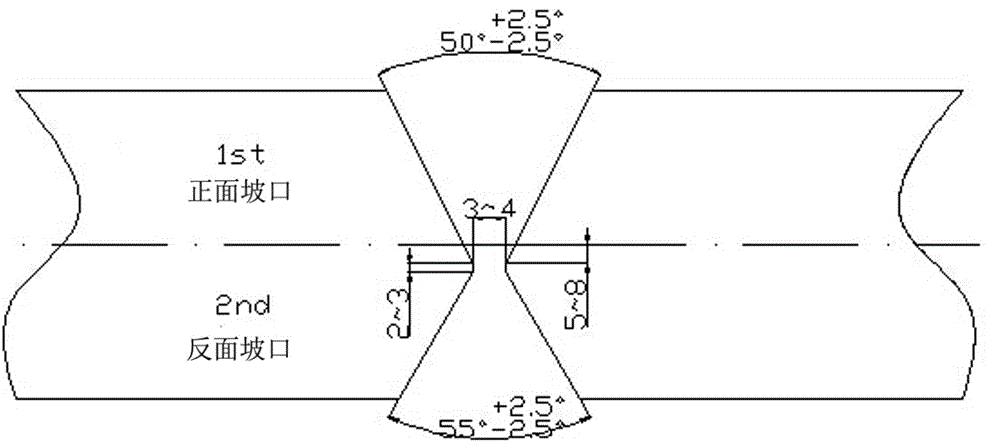

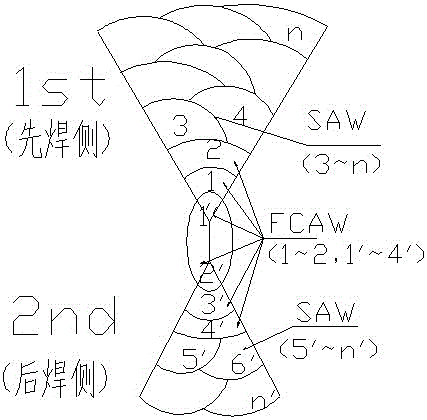

[0027] 1) Joint preparation: X-shaped bevel is adopted for ultra-thick plates (thickness ≥ 150mm), the front bevel angle is 50°±2.5°, the two sides are symmetrically opened, and the bevel depth is t / 2+(5~8)mm (t is the plate thickness, that is, the groove depth is 1 / 2 the thickness of the ultra-thick plate + 5~8mm), the back groove angle is 55°±2.5°, the two sides are symmetrically opened, the groove depth is t / 2-(5~8)mm , The blunt edge is 2~3mm, the joint gap is 3~4mm, and the moisture, grease, impurities and metal oxide film on the surface of the base metal are carefully cleaned before assembly. The groove depth on both sides of the joint is asymmetrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com