Stainless steel braid welding material and manufacturing method thereof

A technology of welding materials and production methods, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of increased harmful effects in the heat-affected zone of the base metal, large welding deformation, and unstable arc, etc., to achieve The effect of saving power energy consumption, small welding deformation, and fast melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

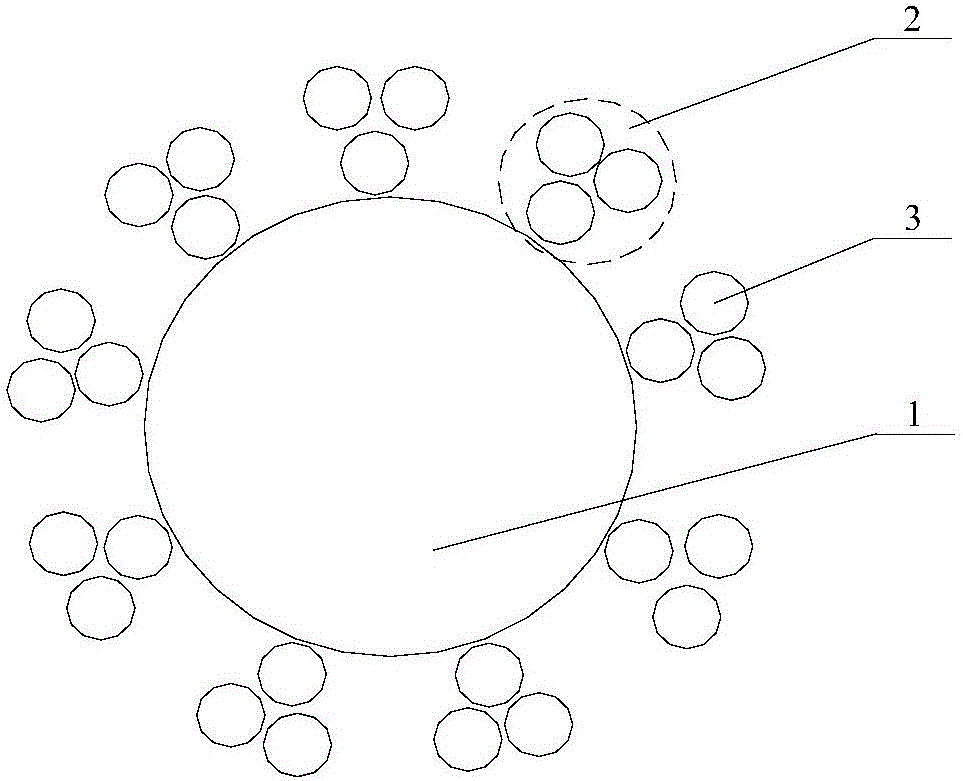

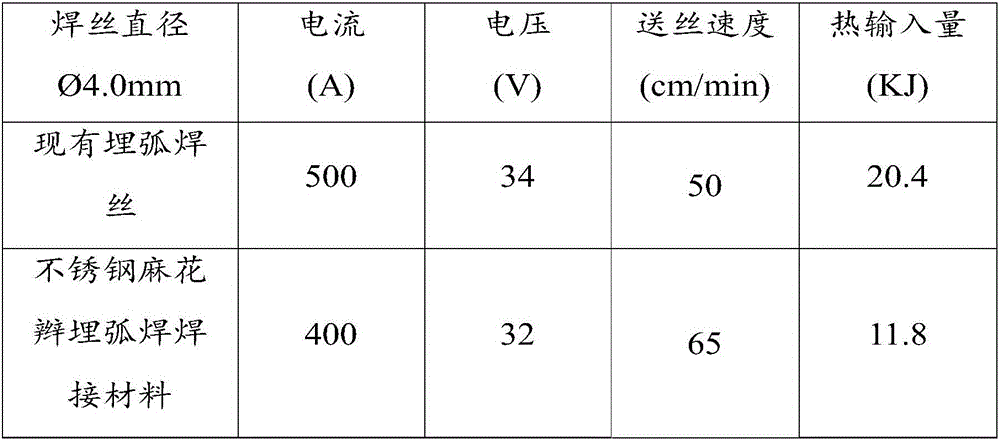

[0052] Example 1: An example of welding material for submerged arc welding

[0053] according to figure 1 As shown, the diameter of the stainless steel braided submerged arc welding material is 4.0mm, the diameter of the welding core 1 is 2.0mm, and 3 thin wires 3 are used to synthesize a steel wire bundle 2, a total of 9 steel wire bundles 2 and the welding core 1 are twisted Strand into stainless steel braided submerged arc welding welding material, the production steps are as follows:

[0054] 1. Production of thin wire 3: The stainless steel coiled wire with a diameter of 5.5mm is drawn for several times to a thin wire with a diameter of 0.5mm, and sent to a heat treatment furnace for automatic wire feeding and annealing heat treatment. The heat treatment temperature is 800 ℃, and the furnace is kept warm Heat treatment time 3 minutes.

[0055] 2. Making steel wire bundle 2: The thin wires obtained in step 1 are twisted through the twisting machine, and the three thin wi...

Embodiment 2

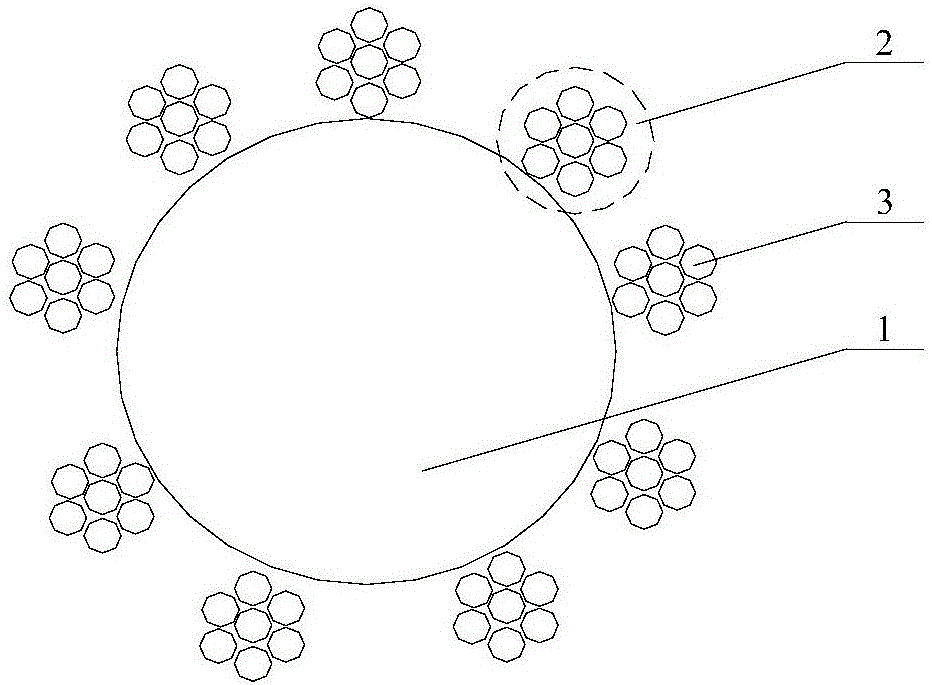

[0063] Embodiment 2: an embodiment of welding material for gas shielded welding

[0064] according to figure 2 As shown, the diameter of the stainless steel braided gas shielded welding material is 2.0mm, the diameter of the welding core 1 is 0.92mm, and 7 thin wires 3 are used to synthesize a steel wire bundle 2, and a total of 9 steel wire bundles 2 and the welding core 1 are twisted Strand into stainless steel braided gas shielded welding material, the production steps are as follows:

[0065] 1. Production of thin wire 3: The stainless steel coiled wire with a diameter of 5.5mm is drawn to a thin wire with a diameter of 0.18mm for many times, and then sent to a heat treatment furnace for automatic wire feeding and annealing heat treatment. The heat treatment temperature is 800 ℃, and the furnace is kept warm Heat treatment time 2 minutes.

[0066] 2. Making steel wire bundle 2: The thin wires obtained in step 1 are twisted through a twisting machine, and 7 thin wires ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com