Hollow fiber ultrafiltration membrane with antibacterial and antipollution functions and preparation method thereof

An ultrafiltration membrane, anti-pollution technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as membrane pore blockage, hollow fiber ultrafiltration membrane membrane pollution, etc. Hydrophilic, long working life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of spinning solution

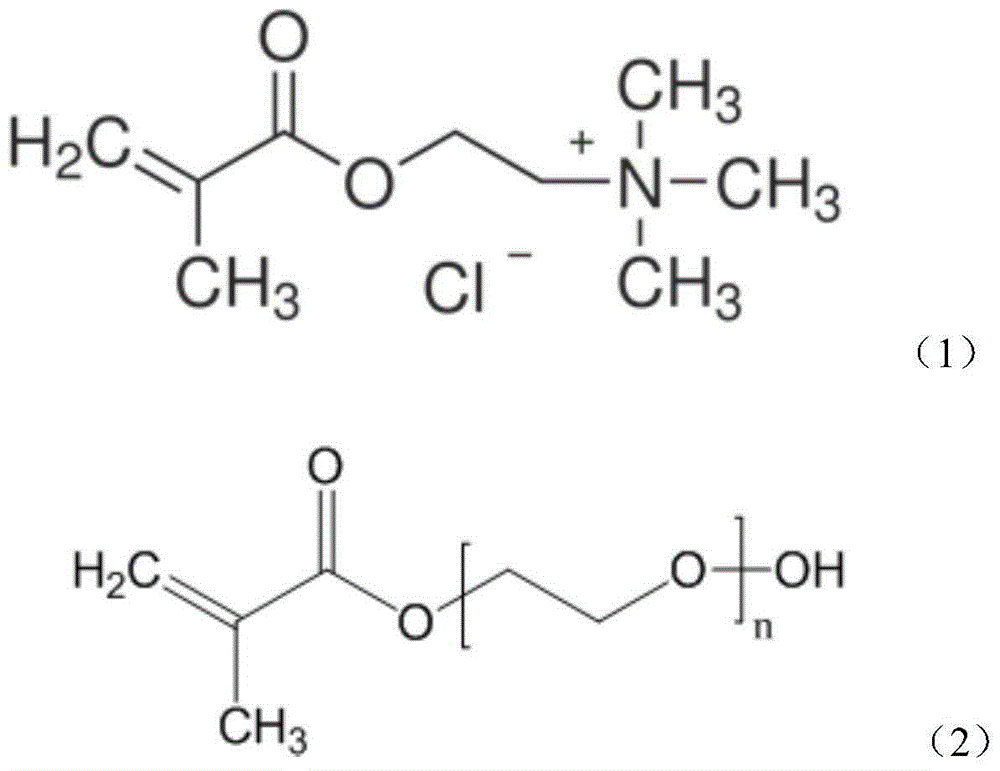

[0036] Using methacryloyloxyethyltrimethylammonium chloride (METAC) and poly(ethylene glycol) methyl ether methacrylate (P(EG)MEMA) as reaction monomers, measure 15 kg of polysulfone as the membrane substrate, METAC5kg, P(EG)MEMA1kg, solvent N,N-dimethylformamide 85kg, the cross-linking agent ethylene glycol dimethacrylate of 1% of total molar weight of reactive monomers and the initiation of 1% of total molecular weight of reactive monomers Agent azobisisobutyronitrile;

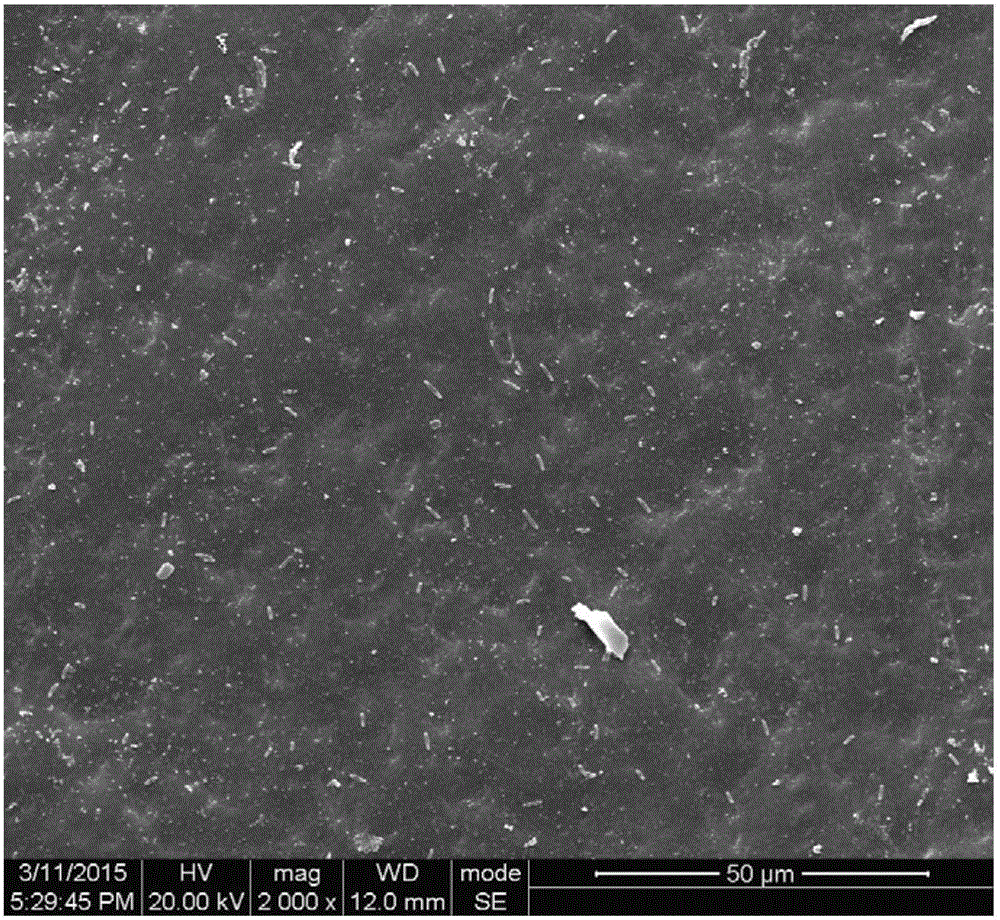

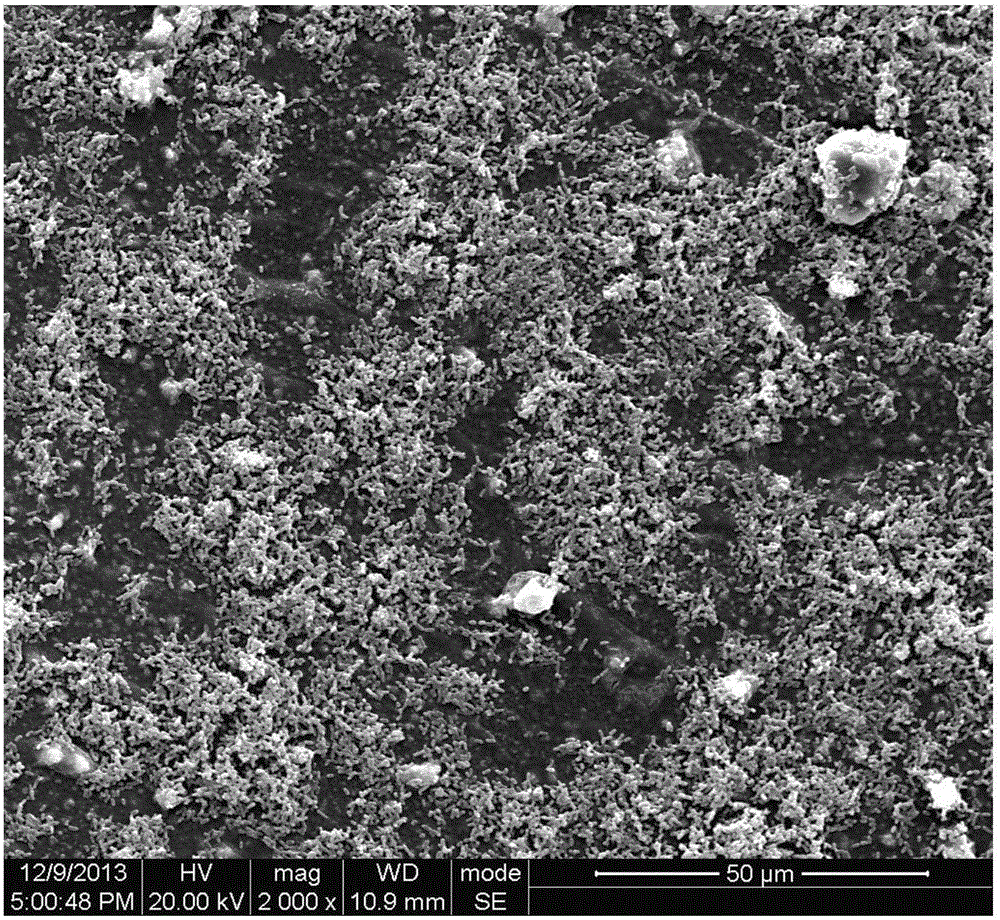

[0037] Add the reaction monomer, cross-linking agent, initiator and solvent into a reaction kettle equipped with a stirrer, a thermometer and a heater, react at 80°C for 12 hours under stirring to obtain a micro-cross-linked gel, and then add the film substrate to the In the micro-cross-linked gel, stir at 80°C until the membrane substrate and the micro-cross-linked gel are evenly mixed, then filter to remove solid impurities, put it in a vacuum drying oven, vac...

Embodiment 2

[0043] (1) Preparation of spinning solution

[0044] Using methacryloyloxyethyltrimethylammonium chloride (METAC) and poly(ethylene glycol) methyl ether methacrylate (P(EG)MEMA) as reaction monomers, measure 14 kg of polysulfone as the membrane substrate, METAC3kg, P (EG) MEMA3kg, solvent N-methylpyrrolidone 85kg, the cross-linking agent ethylene glycol dimethacrylate of 2% of the total molar weight of the reaction monomer and the initiator diperoxide of 1% of the total weight of the reaction monomer Benzoyl;

[0045] Add the reaction monomer, cross-linking agent, initiator and solvent into a reaction kettle equipped with a stirrer, a thermometer and a heater, react at 80°C for 12 hours under stirring to obtain a micro-cross-linked gel, and then add the film substrate to the In the micro-cross-linked gel, stir at 80°C until the membrane substrate and the micro-cross-linked gel are evenly mixed, then filter to remove solid impurities, put it in a vacuum drying oven, vacuumize ...

Embodiment 3

[0051] (1) Preparation of spinning solution

[0052] Using methacryloxyethyltrimethylammonium chloride (METAC) and poly(ethylene glycol) methyl ether methacrylate (P(EG)MEMA) as reaction monomers, measure 20 kg of polysulfone as the membrane substrate, METAC1kg, P (EG) MEMA5kg, solvent dimethyl sulfoxide 80kg, the cross-linking agent ethylene glycol dimethacrylate of 0.5% of total molar weight of reaction monomer and the initiator diperoxide of 4% of total weight of reaction monomer Benzoyl;

[0053] Add the reaction monomer, cross-linking agent, initiator and solvent into a reaction kettle equipped with a stirrer, a thermometer and a heater, react at 80°C for 24 hours under stirring to obtain a micro-cross-linked gel, and then add the film substrate to the In the micro-cross-linked gel, stir at 80°C until the membrane substrate and the micro-cross-linked gel are evenly mixed, then filter to remove solid impurities, put it in a vacuum drying oven, vacuumize at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com