Implementing method for integrated distributed desulfurization and denitrification process of boiler flue gas

A technology for desulfurization and denitrification, boiler flue gas, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of low denitrification capacity, and achieve the effect of improving desulfurization and denitrification efficiency, reducing operating costs, and saving oxidants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

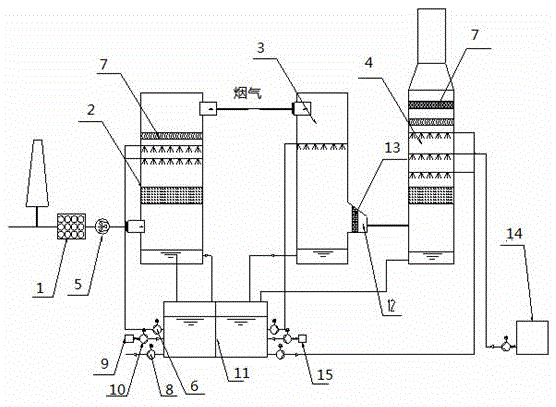

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] Such as figure 1 As shown, the implementation method of a boiler flue gas integrated distributed desulfurization and denitrification process in this embodiment adopts the route of dust removal-desulfurization-oxidation-denitration, and the dust removal adopts the bag filter 1; then enters the desulfurization tower 2, The desulfurization tower 2 uses a packed tower, and the absorbent is a dilute solution of sodium hydroxide; then it enters the oxidation tower 3 for primary oxidation and absorption, and a part of NO is oxidized to NO 2 , the oxidation tower 3 adopts the method of sequential spraying, and the flue gas after the primary oxidation then enters the denitrification tower 4 for secondary absorption and oxidation, and most of the NO is oxidized to NO 2 And absorb, adopt the way of packed tower. The primary oxidation oxidant is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com