Device for picking out wastes and removing dust of upper module and lower module of capsule filling machine

A technology of filling machine and capsule machine, which is applied in the fields of capsule delivery, pharmaceutical formulation, drug delivery, etc. It can solve the problems that empty capsules cannot be completely dropped, affect product quality, and loss of hollow capsules, so as to reduce the loss of powder materials and reduce energy consumption. Consumption and cost are low, and the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further explained by specific examples below.

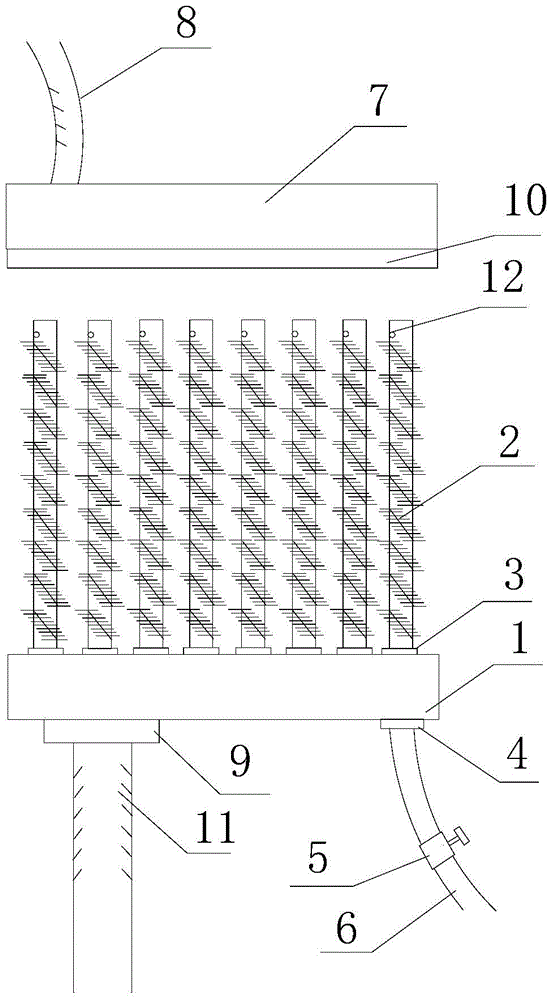

[0021] Such as figure 1 As shown, a capsule filling machine rejects and removes dust from the upper and lower modules, including a device panel 1, the upper part of the device panel 1 is inserted into a perforated stainless steel tube 2 wrapped with an external brush, and the bottom side of the device panel 1 is connected to the synchronous transmission of the capsule machine The shaft 11 is connected to the compressed air pipeline 6 on the other side.

[0022] The synchronous transmission shaft 11 of the capsule machine is connected to the motor, and the device panel 1 is driven by the motor to move up and down.

[0023] The total height of the stainless steel tube is 45-65mm, the bottom diameter is 4-5.5mm, and the top diameter is 4-5mm. The total height of the stainless steel tube is preferably 65mm, the bottom diameter is 5.5mm, and the top diameter is 4mm.

[0024] The brush is wound 10-15 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Tip diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com