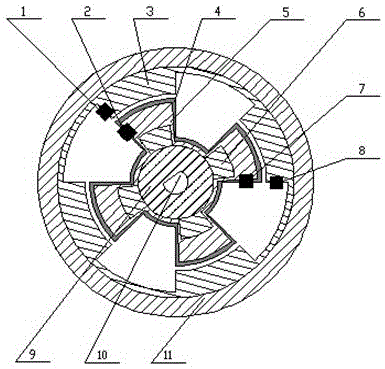

Generation device for generating DC triboelectricity

A power generation device and triboelectric technology, applied in the direction of friction generators, etc., can solve the problems of complex material selection, poor sealing and portability, and inability to be popularized for rotary friction generators, and achieve simple structure, convenient implementation, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

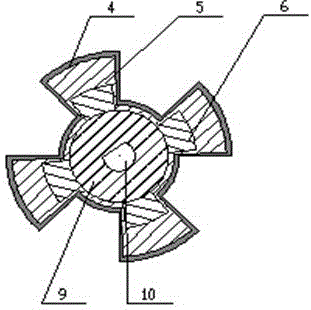

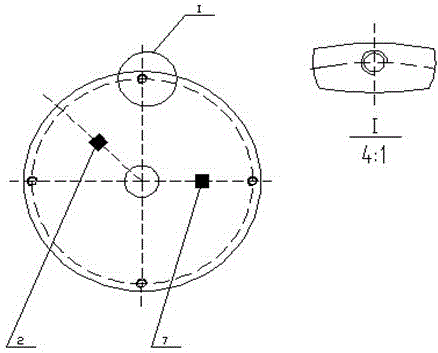

Method used

Image

Examples

Embodiment 1

[0046] The material of the stator friction part is copper; select a flexible polyimide sheet with a thickness of 25-50 μm, ultrasonically clean it for 3-5 minutes, take it out, wash it with a large amount of deionized water and absolute ethanol successively, dry it, and put it Put it into the magnetron sputtering equipment, cover it with a mask, use the copper target with a purity of 99.999% as the sputtering source, and argon as the plasma generation source, first vacuumize the reaction chamber to 5.0×10 -4 Pa, pass in argon gas, adjust the molecular pump plug valve to control the vacuum in the reaction chamber to 1Pa, turn on the AC sputtering source, and the sputtering time is 3~5min, and copper with a thickness of 100~125nm can be obtained on the surface of the polymer; Then the polymer polyimide sheet is pasted on the inner wall of the insulating cylindrical shell 11, wherein the polymer surface serves as the adhesive surface.

[0047] The rotor friction material is made ...

Embodiment 2

[0052] The material of the stator friction part is gold; choose a flexible polyimide sheet with a thickness of 30-50 μm, ultrasonically clean it for 3-5 minutes, take it out, wash it with a large amount of deionized water and absolute ethanol successively, dry it, and put it Put it into the magnetron sputtering equipment, cover it with a mask, use the gold target with a purity of 99.999% as the sputtering source, and argon as the plasma generation source, first vacuumize the reaction chamber to 5.0×10 -4 Pa, feed argon gas, adjust the molecular pump flapper valve to control the vacuum in the reaction chamber to 1Pa, turn on the AC sputtering source, sputter for 2-3min, and obtain gold with a thickness of 50-100nm on the surface of the polymer; then the polymer The polyimide sheet is pasted on the inner wall of the insulating cylindrical shell 11, wherein the polymer surface serves as the adhesive surface.

[0053] The rotor friction material is made of polydimethylsiloxane wit...

Embodiment 3

[0059] The material of the stator friction part is aluminum; choose a flexible polyimide sheet with a thickness of 30-50 μm, ultrasonically clean it for 3-5 minutes, take it out, wash it with a large amount of deionized water and absolute ethanol successively, dry it, and put it Put it into the magnetron sputtering equipment, cover it with a mask, use the aluminum target with a purity of 99.999% as the sputtering source, and argon as the plasma generation source, first vacuumize the reaction chamber to 5.0×10 -4 Pa, pass in argon gas, adjust the molecular pump flapper valve to control the vacuum in the reaction chamber to 1Pa, turn on the AC sputtering source, sputter for 2~3min, and obtain aluminum with a thickness of 75~100nm on the surface of the polymer; then the polymer The polyimide sheet is pasted on the inner wall of the insulating cylindrical shell 11, wherein the polymer surface serves as the adhesive surface.

[0060] The rotor friction material is made of polytetra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com