Boiler denitration control method based on outlet NOx content control and system thereof

A control method and control system technology, applied in the field of boiler denitrification control and system based on outlet NOx content control, can solve problems such as increased operating costs, damage to downstream main equipment, and excessive denitrification, so as to improve the system's anti-disturbance ability, Effect of controlling denitrification operation cost, preventing corrosion and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

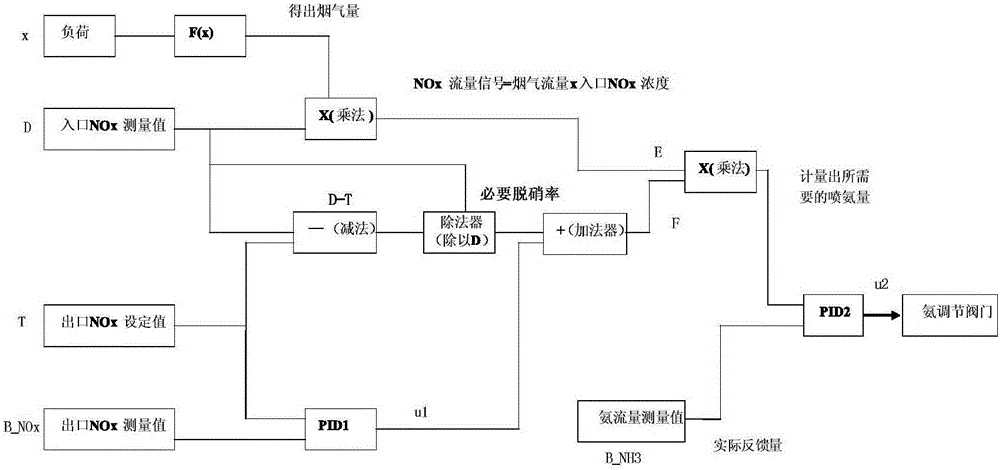

[0045] Such as figure 1 , in the boiler denitrification control process, the following calculation and control processes are involved:

[0046] 1. Calculate the flue gas flow rate of the boiler. The flue gas flow rate of the new ammonia injection automatic logic is based on the empirical value of the corresponding relationship between load and flue gas volume, and through the segmented function FX [this function is obtained based on long-term operation experience in the production process. A more general general formula, applicable to most cases], for inlet flue gas NO x The concentration is corrected, and the ultimate goal is to obtain a more accurate demand for ammonia supply.

[0047] If the boiler is multi-coal mixed combustion, when the coal quality changes, the corresponding relationship between the load and the flue gas volume will also change, and the parameters of FX can be adjusted appropriately according to the actual situation to meet the needs of automatic adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com